Continuous power supply device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

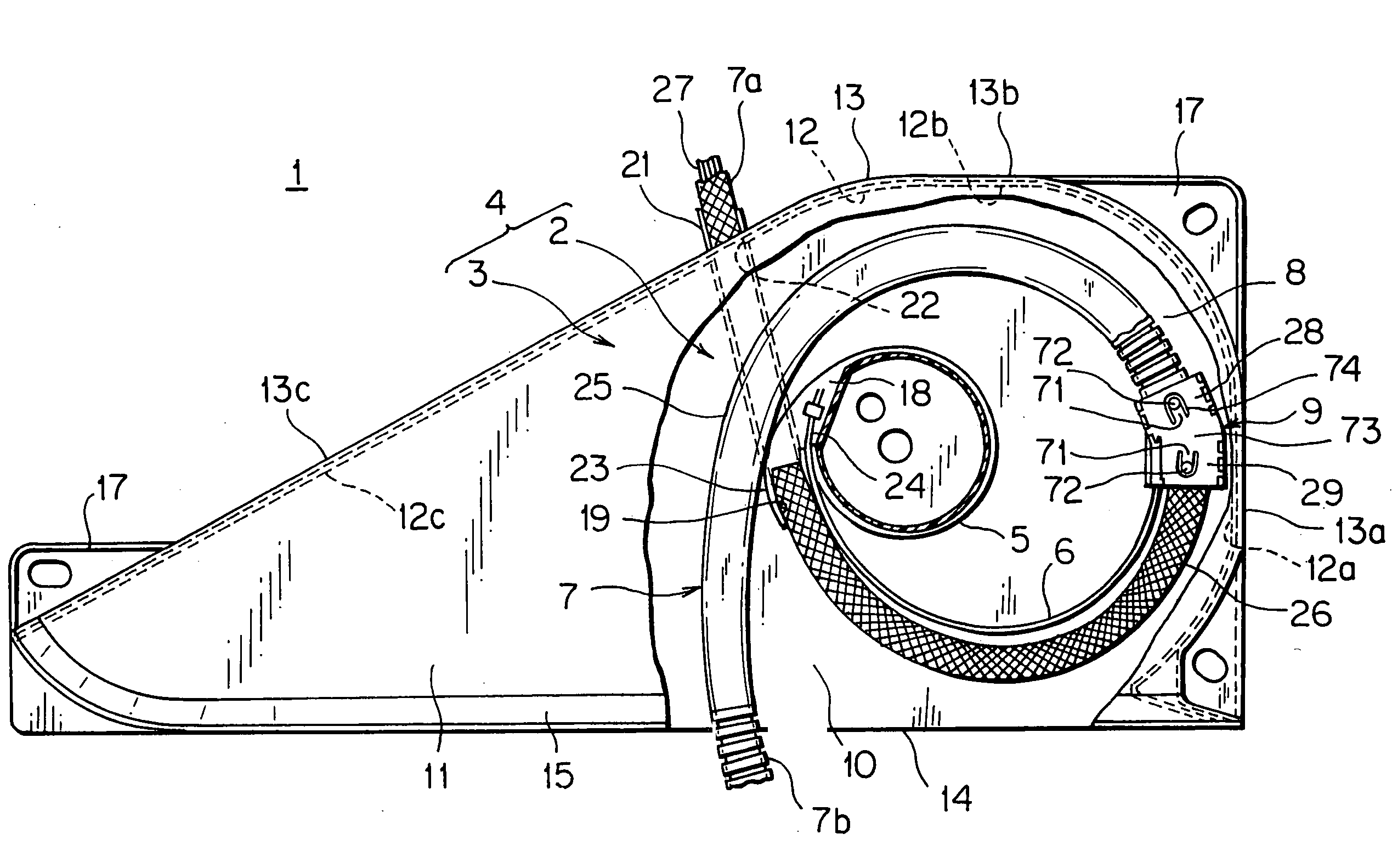

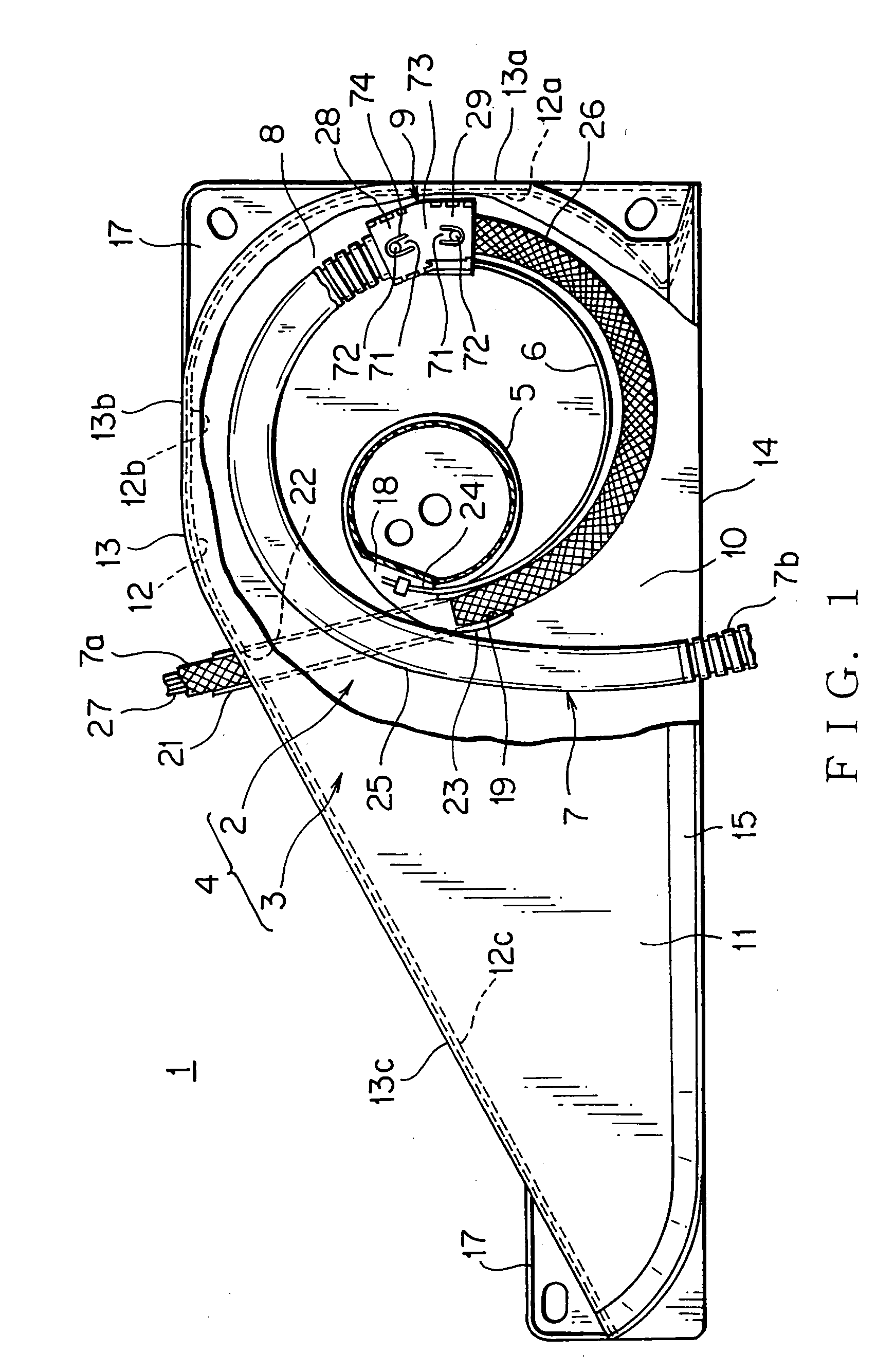

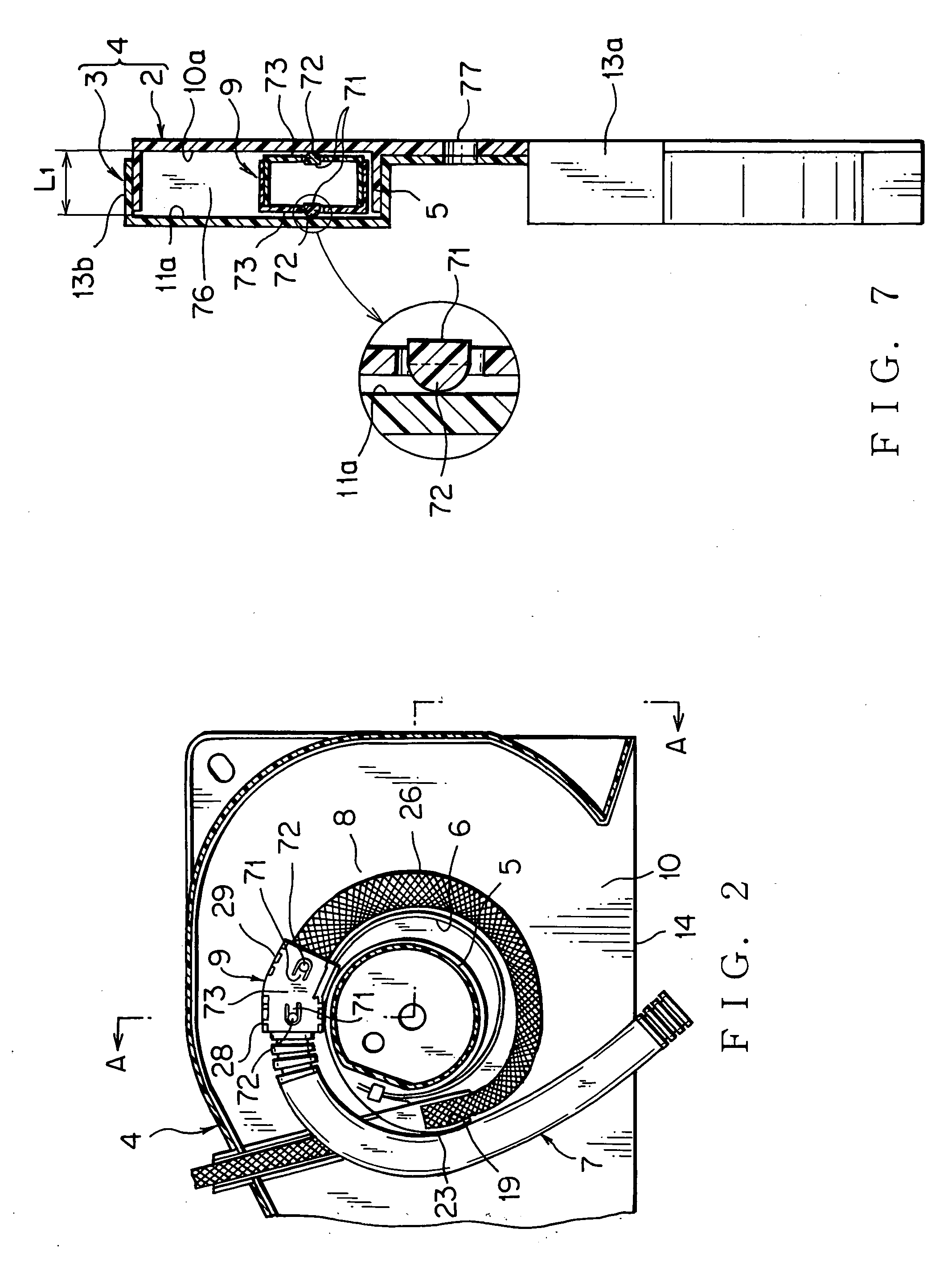

[0046]FIGS. 1, 2 show an embodiment of a continuous power supply device according to the present invention.

[0047] A continuous power supply device 1 includes a protector 4 having a base 2 made of synthetic resin and a cover 3, a metal flat spring 6 curved freely along an annular wall 5 inside the base 2, a wiring harness 7 wired outside the flat spring 6 to be bent in a loop shape along the annular wall 5 and a spring holder 9 made of synthetic resin, which is fixed at a front end of the flat spring 6, for holding the wiring harness 7 to connect and fix a protection tubes 25 and 26, which are outer covers of the wiring harness 7, with each other at a loop 8 of the wiring harness 7. The spring holder 9 includes elastic arms 71, which are continuously and elastically in contact with an inner wall of each base plate 10, 11 of the base 2 and the cover 3 of the protector 4, for preventing a sound noise. The power supply device 1 is usually installed in a slide door (not shown) of a vehi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com