Motorcycle handlebar pipe structure

A technology for handlebars and motorcycles, used in steering mechanisms, bicycle accessories, transportation and packaging, etc., can solve problems such as increased safety hazards, the impact of rigidity of the whole vehicle, and the connection is not firm, to improve safety, strengthen strength, The effect of making the most of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

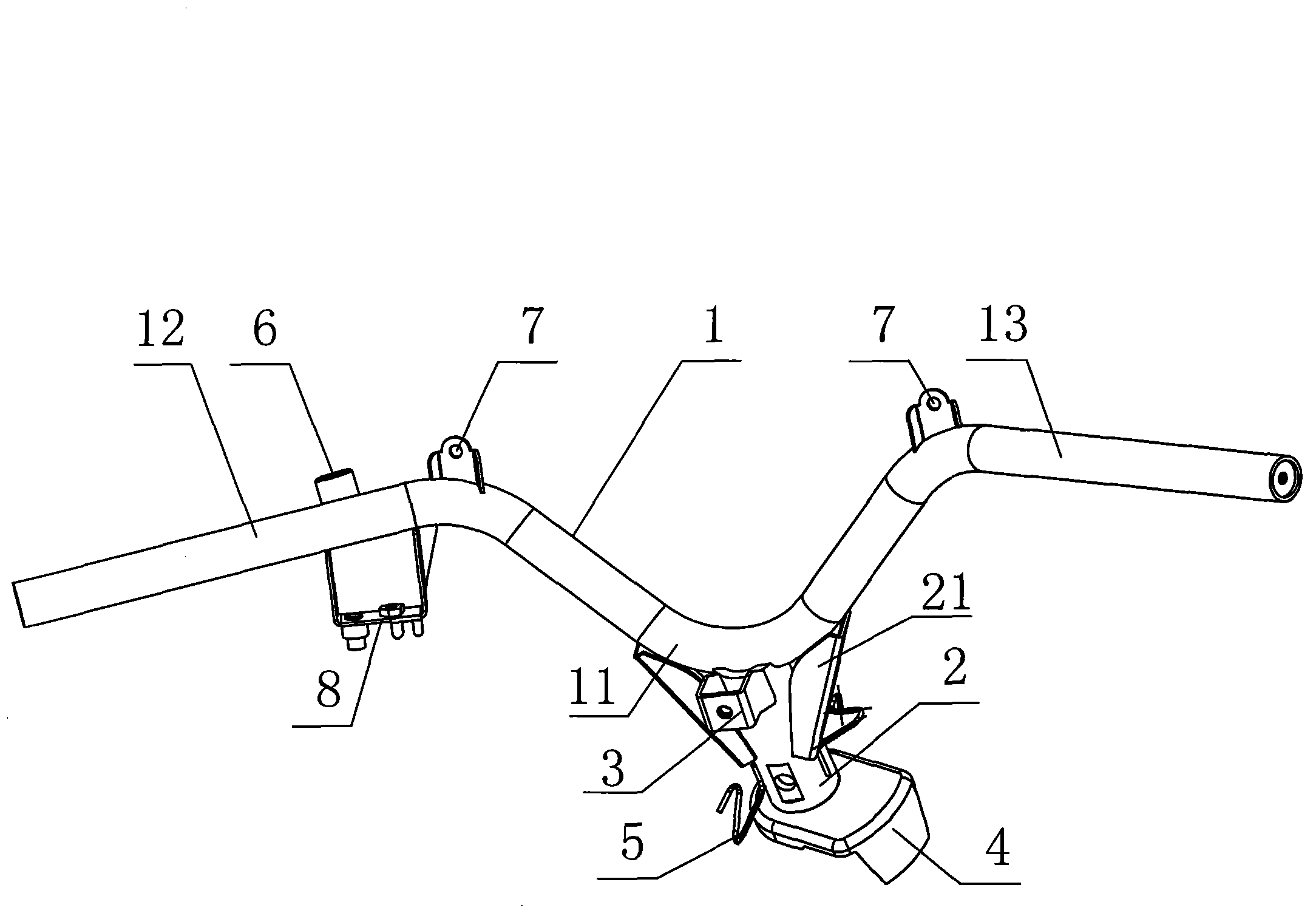

[0009] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention.

[0010] See attached figure 1 , the motorcycle handle pipe structure of the present invention comprises a handle pipe body 1, the handle pipe body 1 is a round steel pipe, the two ends of the handle pipe body 1 are provided with a left hand handle 12 and a right hand handle 13, and the right hand handle is also used To install the handle glue and the oiler fixing seat; the middle position of the handle pipe body 1 is provided with a bending part 11 that bends forward and downward, and the lower part of the bending part 11 is fixedly connected to the frame riser 2, and the frame riser 2 Ribs 21 are welded between the two sides and the curved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com