Hinge wiring harness buckling structure

A clasp structure and wire harness clip technology, which is applied in the direction of electrical components, can solve the problems of affecting the strength of the hinge and the inconvenience of adjusting the installation position of the harness clasp, achieving the effect of good versatility and improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

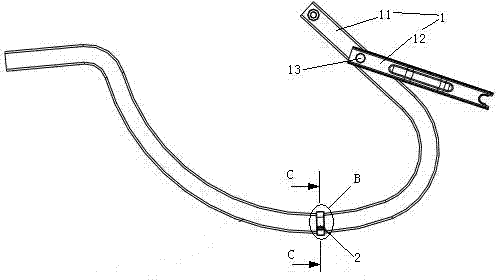

[0030] Embodiment one, see figure 1 , a hinged wire harness buckle structure, comprising a hinge 1 and a wire harness buckle 2 .

[0031] The hinge 1 includes a first connection part 11 and a second connection part 12 , and the first connection part 11 and the second connection part 12 are connected together by a hinge shaft 13 . The first connecting part 11 and the second connecting part 12 can rotate in a plane around the hinge axis 13 . The first connecting portion 11 is a rod-shaped structure. The cross sections of the first connecting portion 11 are congruent geometric figures. The entire first connecting portion 11 is a buckle installation section of the wire harness.

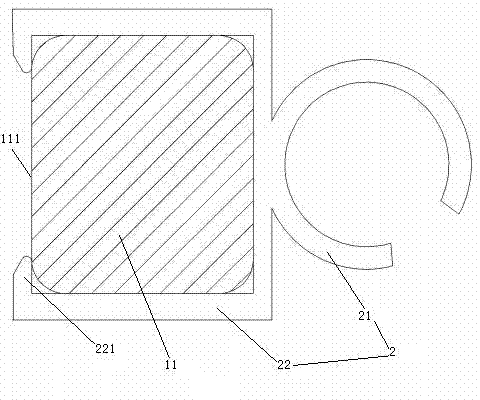

[0032] see figure 2, the wire harness buckle 2 includes a fixed wire harness portion 21 and a clip 22 . The fixed wire harness part 21 is a circular split ring structure with an elastic integral structure. The chuck 22 is a square split ring structure with elasticity. The fixed wire harness part 2...

Embodiment 2

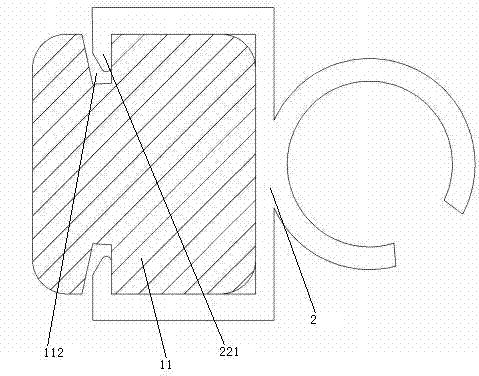

[0034] Embodiment two, see image 3 , the difference from the first embodiment is: the upper and lower surfaces of the first connecting part 11 are respectively provided with a groove 112 extending along the direction of the center line, and the hook head 221 is hooked on the groove 112 .

Embodiment 3

[0035] Embodiment three, see Figure 4 , the difference from the first embodiment is: the two ends of the first connecting portion 11 are provided with plate-shaped mounting heads 114 . The middle part of the first connecting portion 11 is provided with a wire harness buckle installation section 113 . The buckle installation section 113 of the wire harness is a rod-shaped structure. The wire harness buckle 2 is connected to the wire harness buckle installation section 113 .

[0036] see Figure 5 , the cross-section of the buckle installation section 113 of the wire harness is circular, and the clip 22 is a circular split ring structure with elasticity. A fixing surface 111 is cut out on the rear surface of the buckle installation section 113 of the wire harness. The fixing surface 111 extends along the direction of the centerline of the buckle installation section 113 of the wire harness. The generatrix of the fixing surface 111 is a straight line.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com