Wire harness clamping mechanism

A clamping mechanism and wire harness technology, used in workpiece clamping devices, manufacturing tools, etc., can solve the problems of fixing the end of the wire harness, unable to adjust the wire harness, affecting the detection of the wire harness, etc., to achieve the effect of facilitating detection and ensuring stable clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

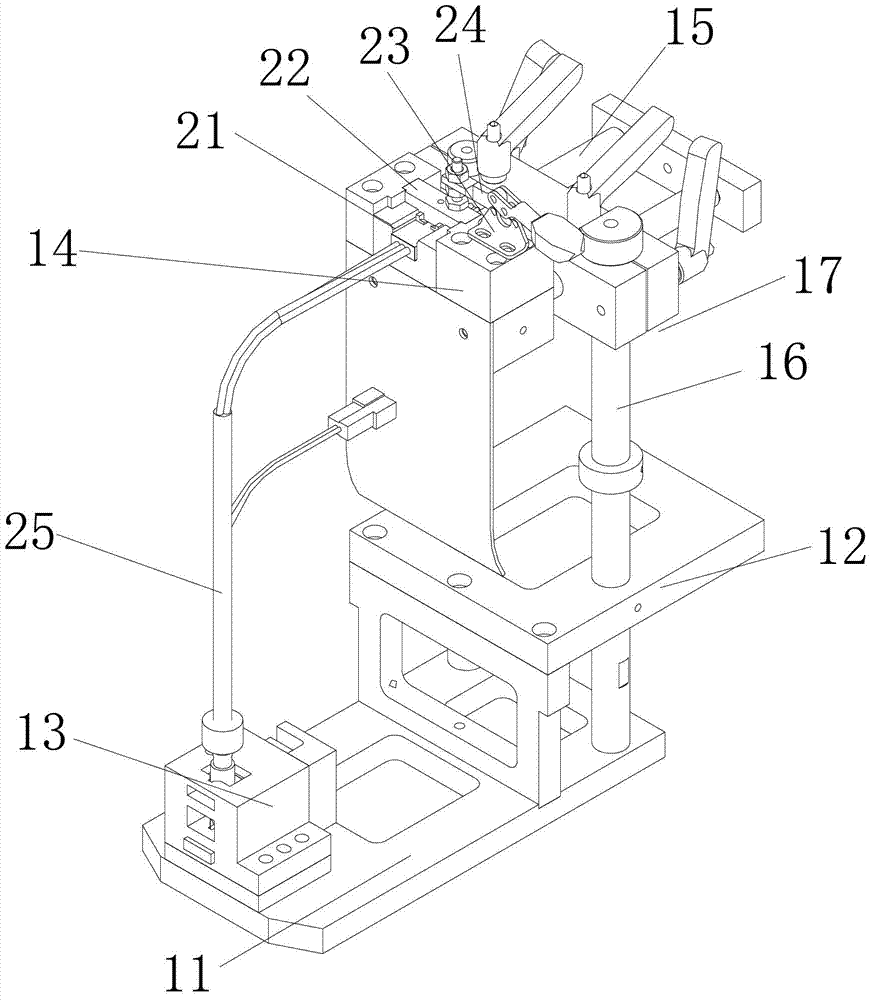

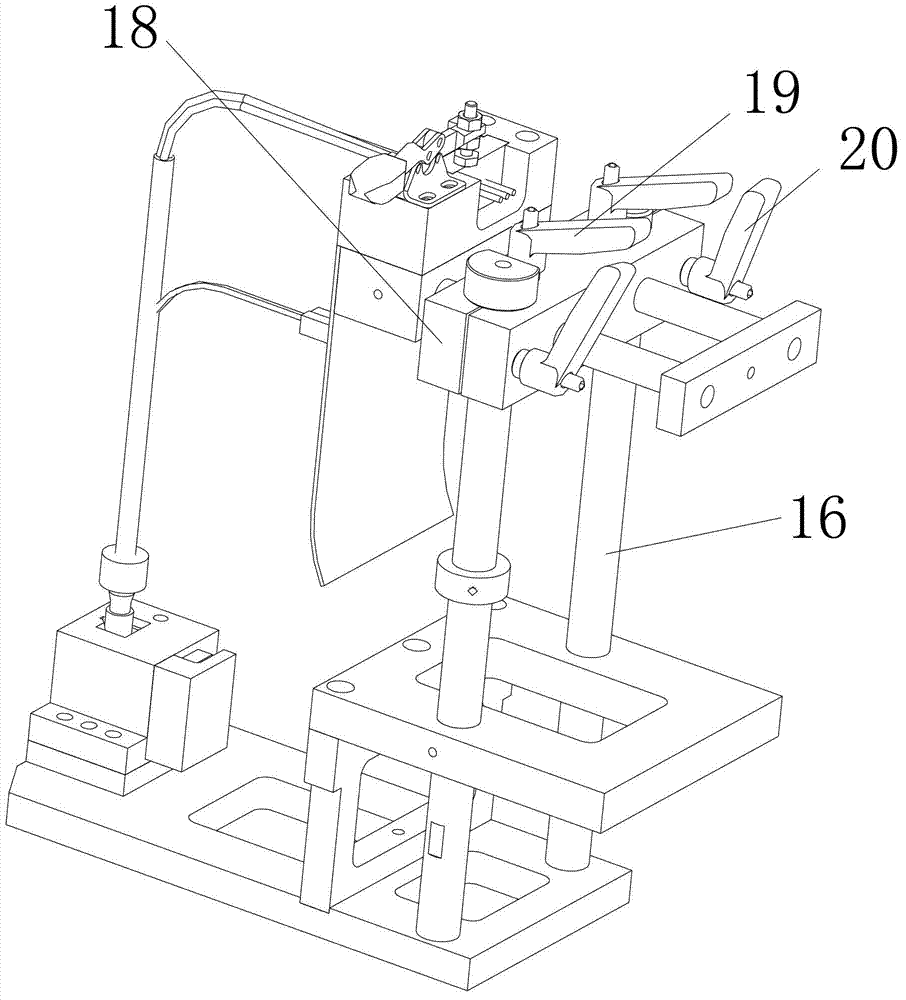

[0016] Such as Figure 1-2 As shown, a wire harness clamping mechanism includes a base 11 , a bracket 12 , a wire harness insertion block 13 , a wire harness fixing block 14 , a horizontal guide rail 15 , a vertical guide rail 16 and a sliding block 17 . The rear end of the base 11 is provided with a wiring harness plugging block 13, the front end of the base 11 is provided with a bracket 12, the top of the bracket 12 is provided with a wiring harness fixing block 14, and the front of the wiring harness fixing block 14 is provided with a sliding block 17, sliding Block 17 is made up of two sliding plates 18 provided with transverse openings and vertical openings. Two horizontal guide rails 15 pass through the transverse opening of the sliding block 17 and are connected to the wire harness fixing block 14 , and two vertical guide rails 16 pass through the vertical open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com