Automotive RF male connector and female connector and connector assembly

A technology of male connectors and connectors, which is applied to parts, connections, and two-part connection devices of connection devices, etc., which can solve the problems of easy loosening of solder joints between RF antennas and PCB boards, unstable signal transmission, and small insertion force, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

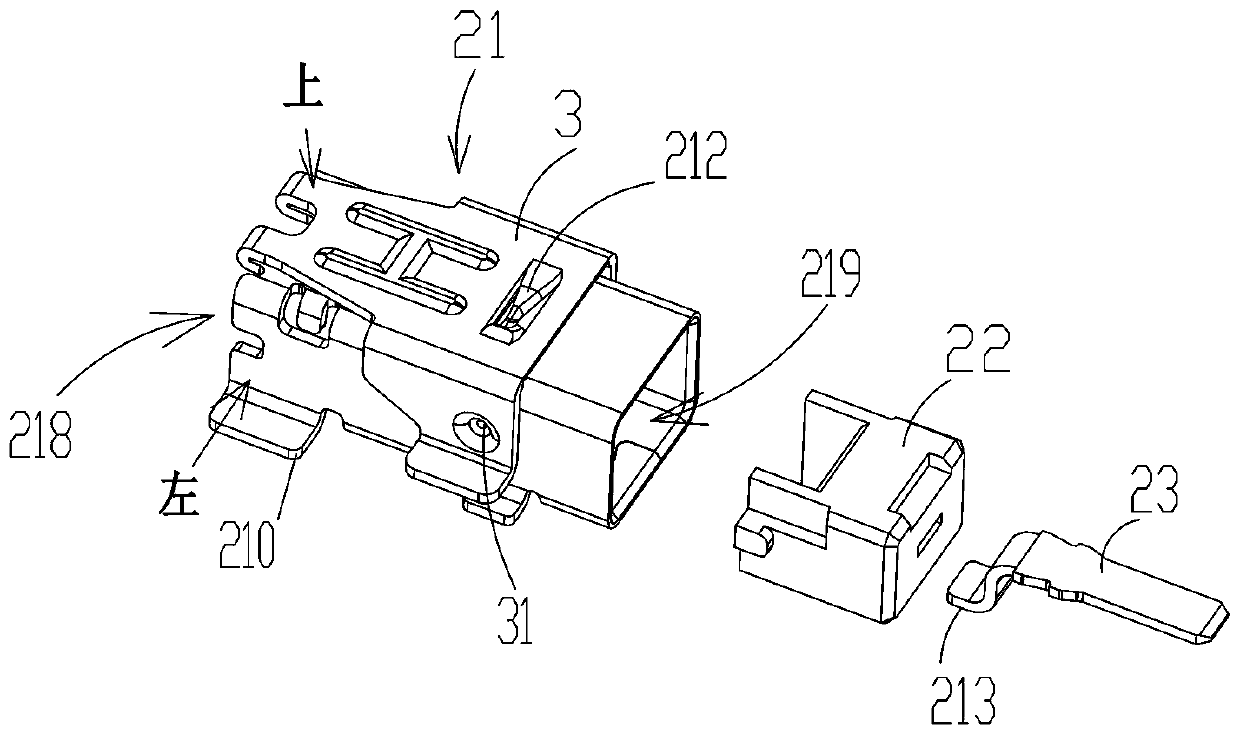

[0040] The present invention also provides a female connector, image 3 and Figure 4 Shown is an embodiment of a female connector, a female connector, including a female housing 21, a female plastic 22 and a female terminal 23, and one end of the female housing 21 is provided with a first socket for receiving a male connector. An opening 219, the left and right sides of the female base housing 21 are partially extended outward to form at least one first veneer 210, the first veneer 210 is perpendicular to the left and right sides, The first bonding panel 210 is used for bonding with the PCB board, thereby replacing the technology in which the wiring harness 9 is directly welded to the PCB board in the prior art; the front and rear ends of the female seat plastic 22 are connected, and the female seat The seat plastic 22 is set in the female seat shell 21; the female seat terminal 23 extends into the female seat plastic 22, the female seat terminal 23 is installed in the femal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com