Combined lathedog for fixing harnesses and pipelines

A combined and fixed line technology, applied in the direction of pipeline supports, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the problems of complicated clamp installation process and high cost, and achieve simple structure, low manufacturing cost and convenient installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the present invention is further described:

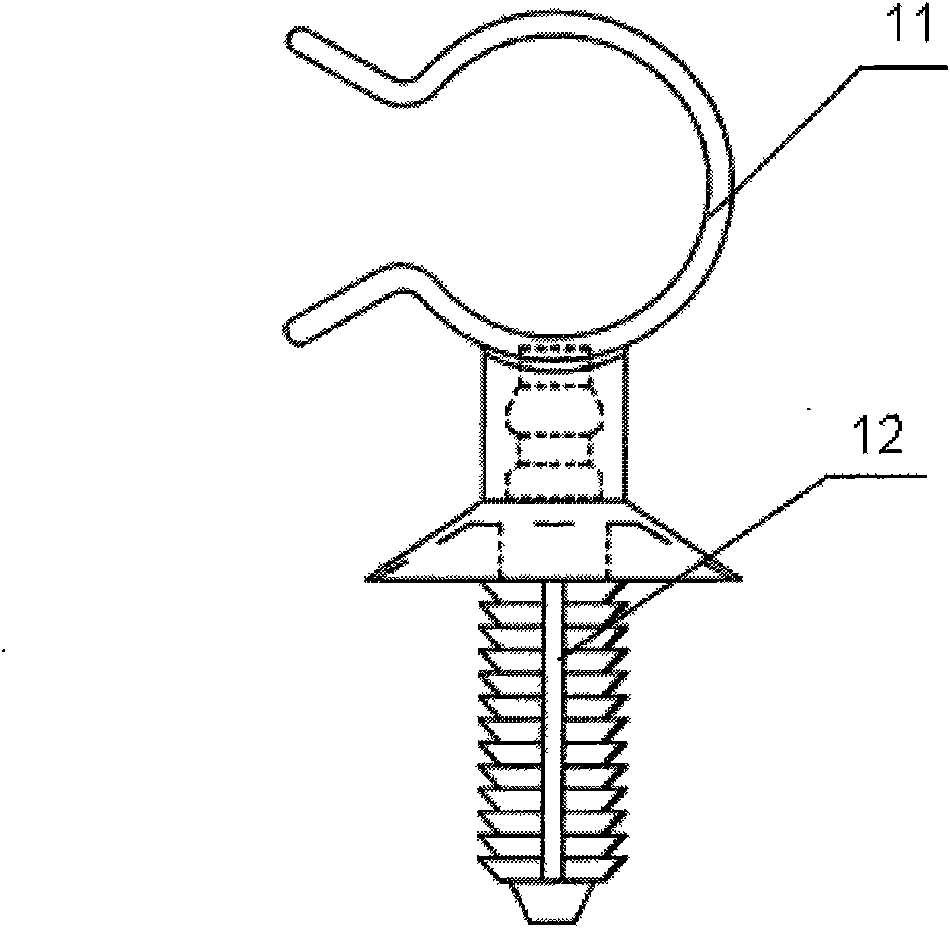

[0016] Such as figure 1 As shown, the combination clamp 1 is composed of a collar 11 and a buckle 12 .

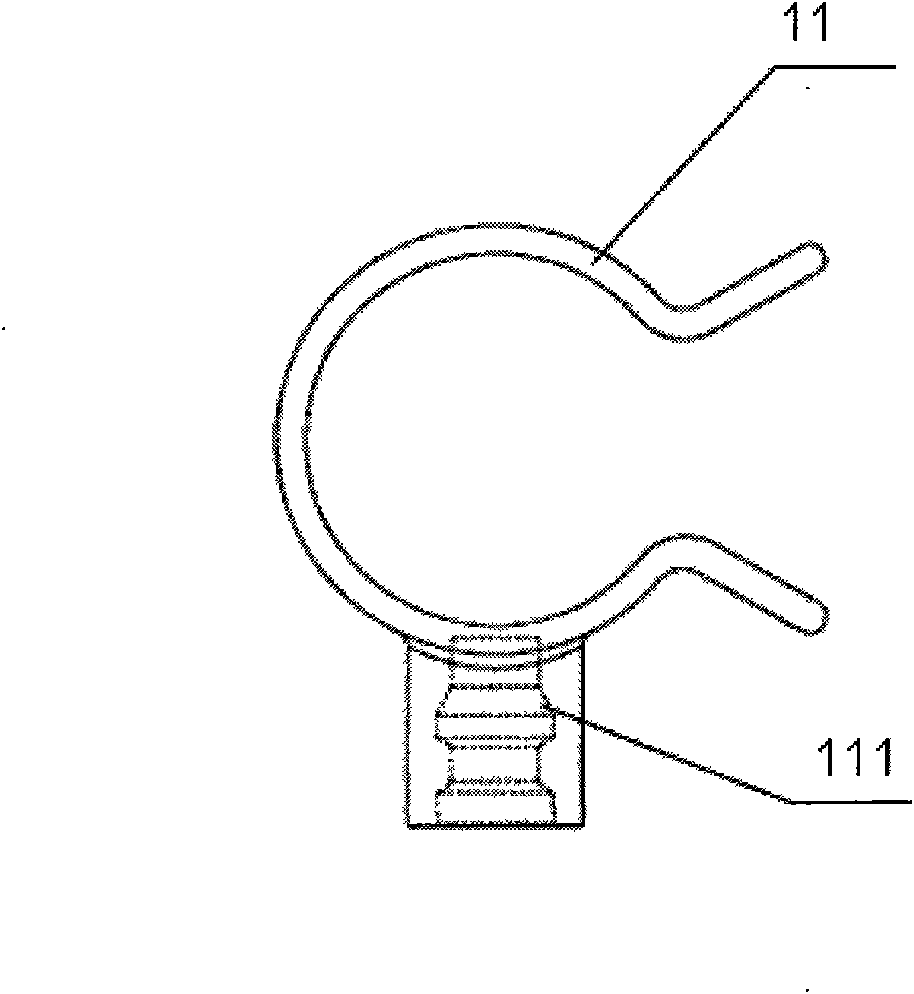

[0017] see figure 2 , The collar 11 is circular, with an opening on the front side, and a connecting pipe 111 with a stepped slot structure is fixed on the lower part of the collar.

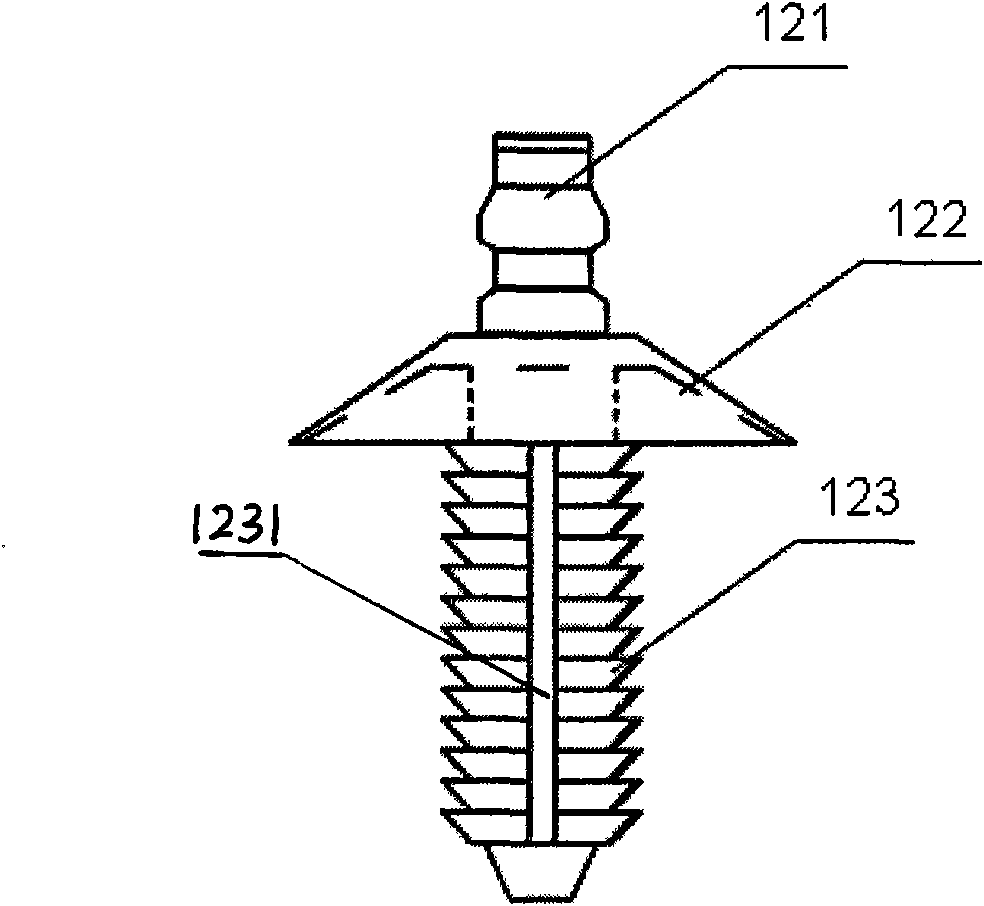

[0018] see image 3 , The buckle 12 is composed of a chuck head 121 , a lampshade-type snap cap 122 and an installation pawl 123 . The chuck 121 has a stepped structure corresponding to the stepped groove of the connecting pipe 111 . The buckle 12 cooperates with the connecting pipe 111 of the collar 11 through the chuck head 121 , and the buckle 12 can rotate in the connecting pipe of the collar 11 so as to fix the pipeline in 360-degree directions. The cap 122 of the buckle 12 is a lampshade type, and its lower edge is used to abut on the installation surface (such as the installation b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com