Operation method of concrete box girder sling by using bevel attaching mechanisms

A technology of concrete box girder and operation method, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of increased manpower and material resources expenditure, complicated operation, small contact area, etc., to improve hoisting safety, simplify hoisting steps, Even pressure distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

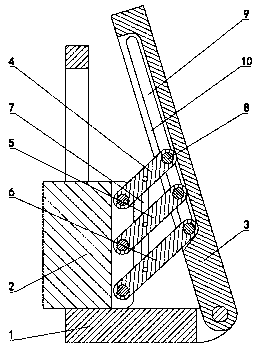

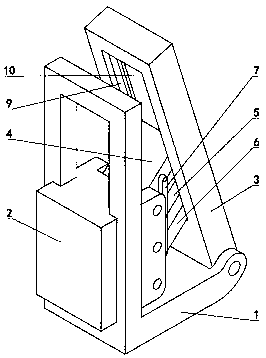

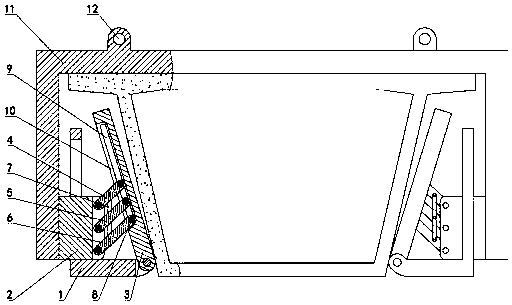

[0013] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0014] combine Figure 1 to Figure 4 , the present invention provides a kind of bevel fitting mechanism, including a base 1 arranged horizontally, the left end of the base 1 is installed with a connecting block 2 that is above the base 1 and can slide vertically on the base 1, the base The right end of 1 is hinged with an extrusion plate 3 inclined to the left; the connecting block 2 has a first connecting rod 4, a second connecting rod 5 and a third connecting rod placed on the right side of the connecting block 2 and parallel to each other. Rod 6, the left end of the first connecting rod 4, the second connecting rod 5 and the third connecting rod 6 are hinged on the right end of the connecting block 2, and the right side of the connecting block 2 has a vertical rod 7, which is connected with the first connecting rod si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com