Electric connector sealing structure

A sealing structure and electrical connector technology, applied in the parts, connections, circuits and other directions of the connecting device, can solve the problems of poor sealing at the joint, cracks in the glue-filled sealing layer, and decreased sealing of the connector, and achieve a good sealing degree. , High sealing level, convenient construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

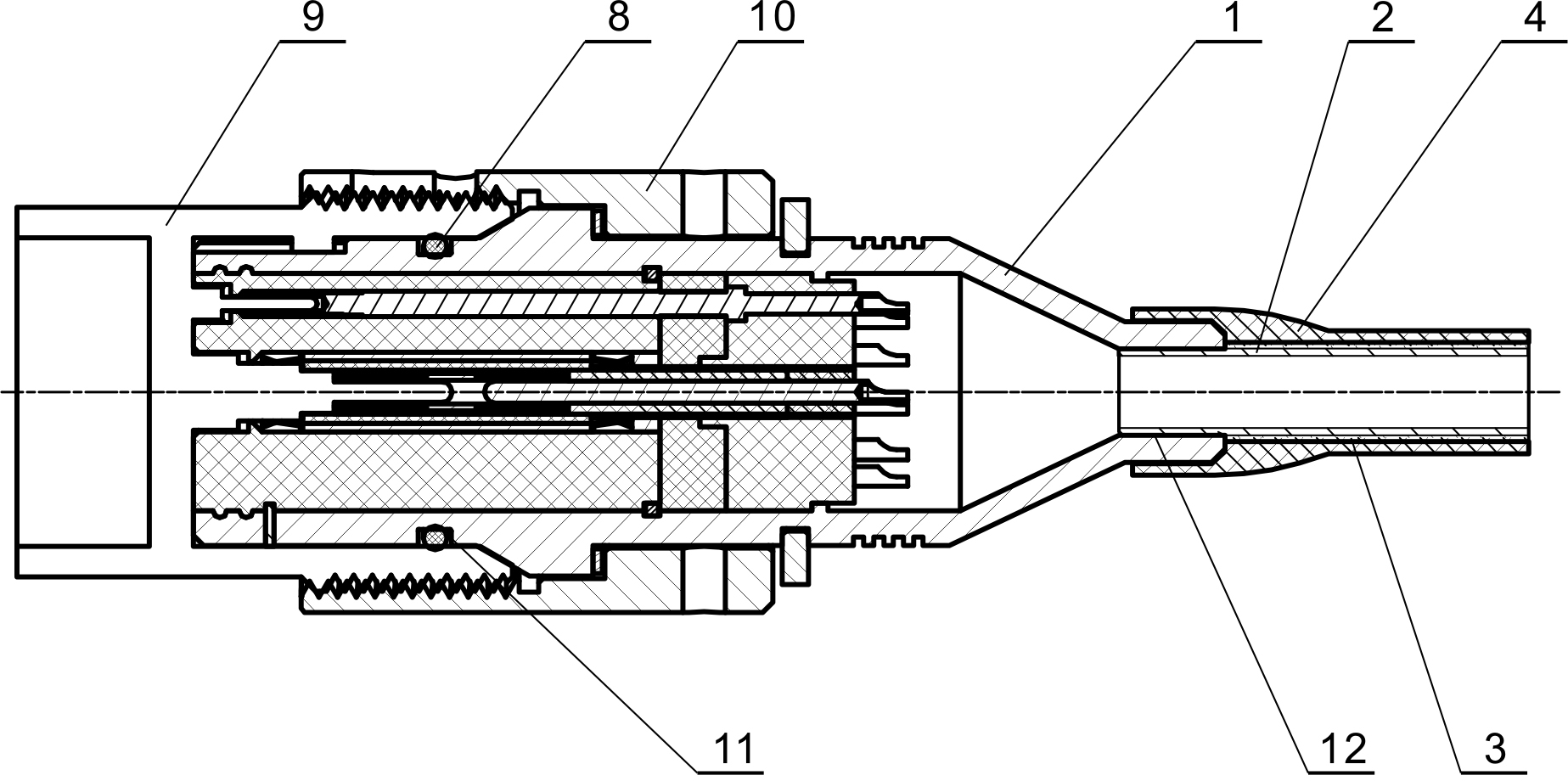

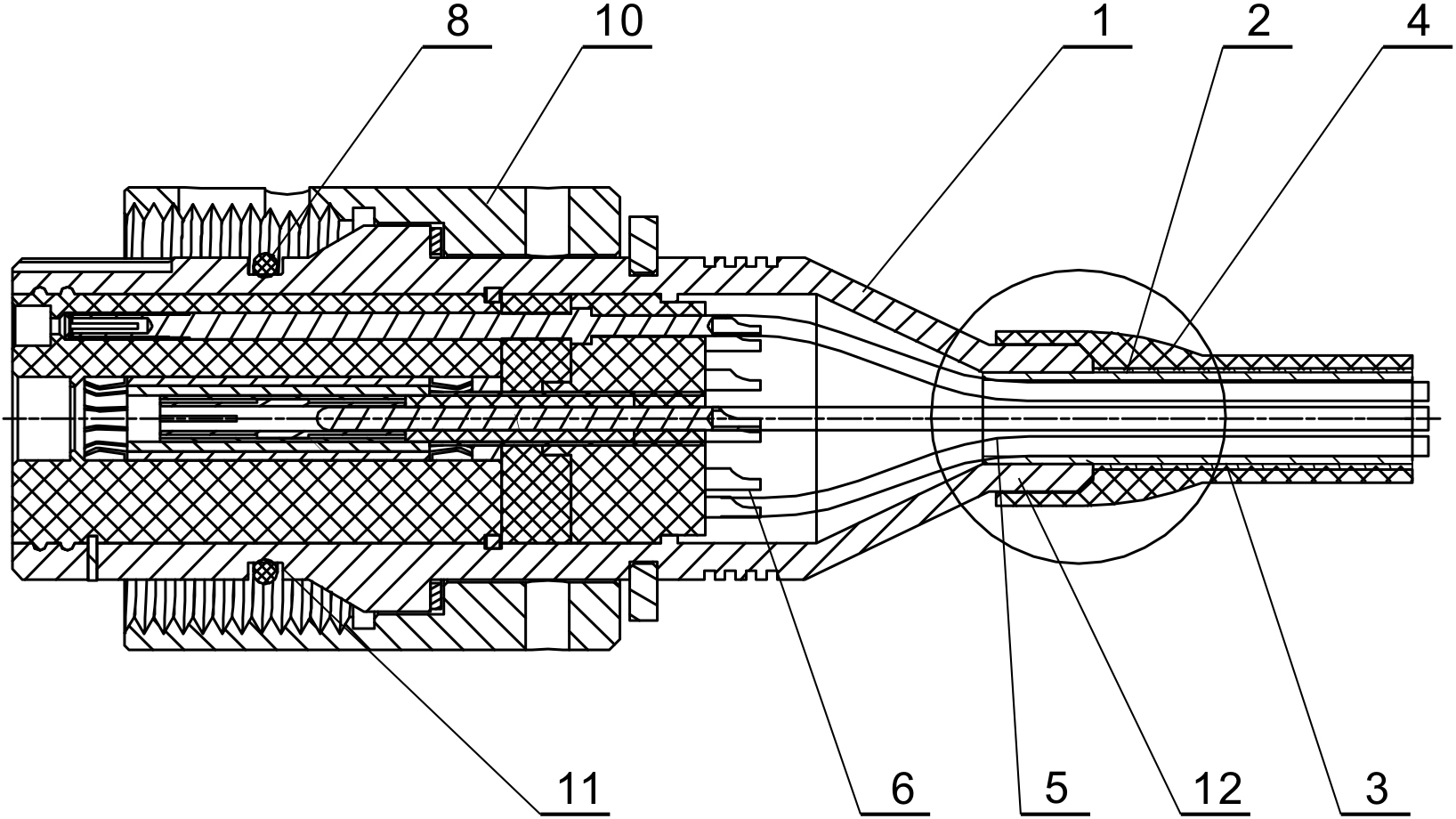

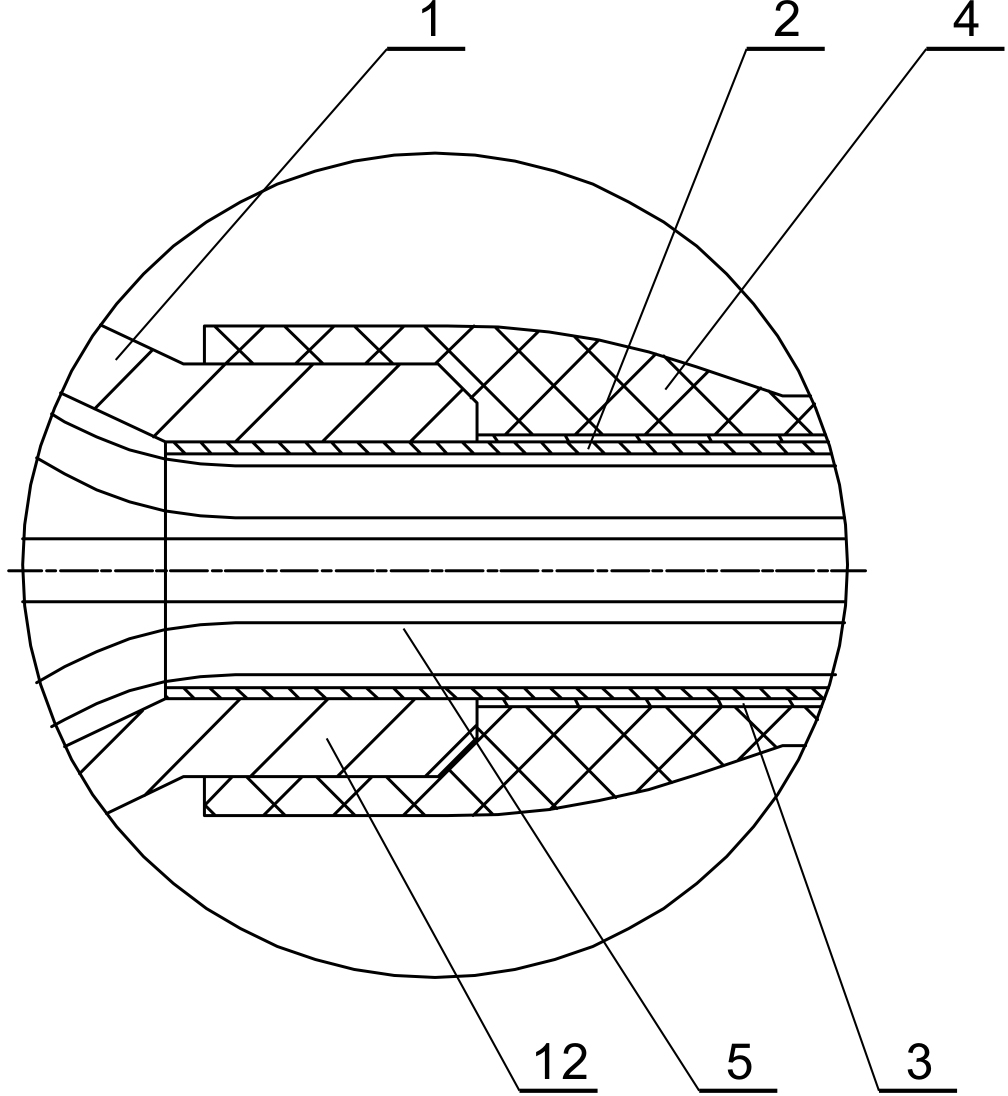

[0010] refer to figure 1 , figure 2 , image 3 , the present invention includes a plug shell 1, a copper tube 2, a heat shrinkable tube 3, a rubber sleeve 4, a sealing ring 8, a socket 9 and a connecting nut 10, the plug shell 1 is provided with a sealing groove 11 and a cable socket 12, The socket 9 is provided with external threads; the copper tube 2 is partially inserted into the cable socket 12 and welded thereto, the heat shrinkable tube 3 is wrapped on the exposed surface of the copper tube 2, and the rubber sleeve 4 is wrapped around the wire of the plug shell 1. The outer surface of the cable socket 12 and the heat shrinkable tube 3, the sealing ring 8 is set in the sealing groove 11 of the plug shell 1, the socket 9 is set on one end of the plug shell 1 and compresses the sealing ring 8, and the connecting nut 10 is set on the other end of the plug shell 1 And engage with the external thread of socket 9.

[0011] The present invention is used like this:

[0012] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com