Sealing structure of pipe faucet of concrete

A technology of concrete pipe and sealing structure, which is applied in the direction of sleeve/socket connection, pipe/pipe joint/fitting, and through components, etc. It can solve the problems of affecting the sealing performance of pipelines, easily scratching the sealing rubber ring, and affecting the cost performance of pipes, etc. Achieve the effects of saving production cost, improving the overall sealing level, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

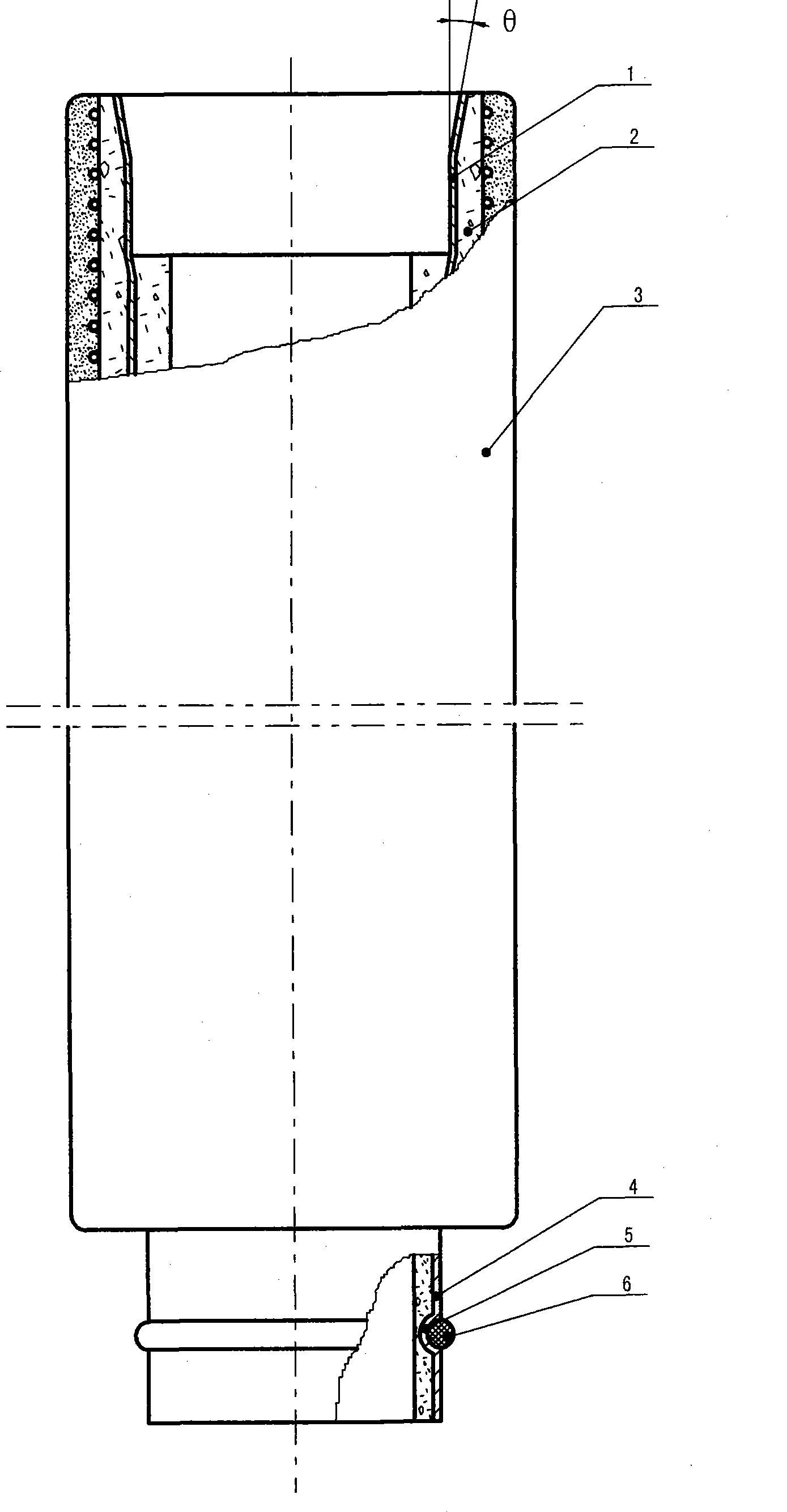

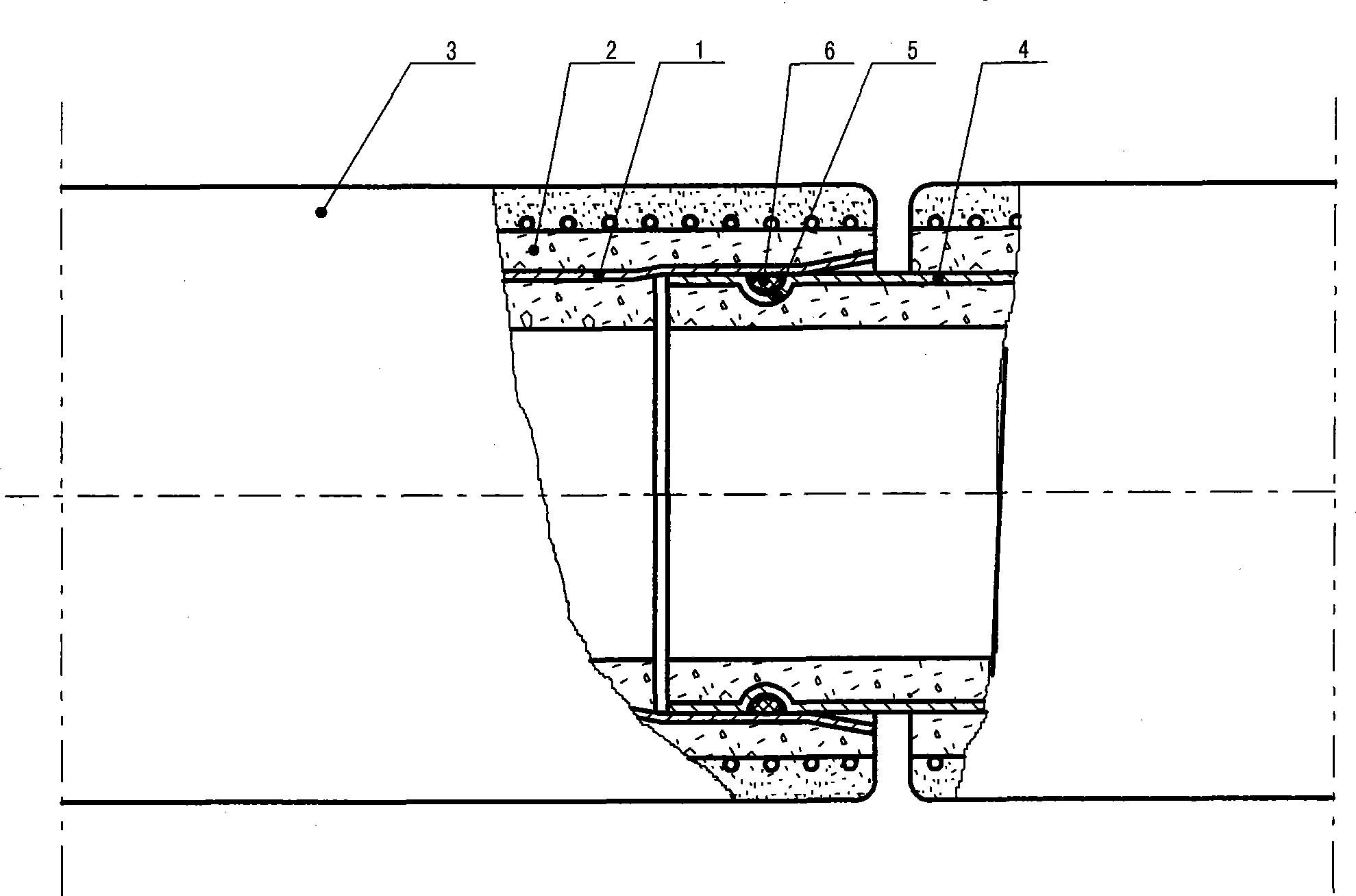

[0016] The sealing structure of the concrete pipe socket, its concrete pipe is composed of a socket 1, a socket 4, and a pipe body 3, and the socket and the socket are fixed in the pipe core 2 at both ends of the pipe body. The technical innovation point of the present invention is: an annular groove 5 is formed radially and coaxially on the outer wall of the concrete pipe socket, and a sealing rubber ring 6 is embedded in the annular groove. When two concrete pipes are connected, the sealing rubber ring can effectively seal the gap between the socket and the socket (see figure 2 ).

[0017] The cross-sectional shape of the annular groove is semicircular, elliptical or square, and it is semicircular as shown in the drawings of this embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com