Back-up buzzer assembly

An alarm and assembly technology, which is applied to vehicle components, sound signal devices, bases/shells, etc., can solve problems such as electronic failure, small contact area between connectors and shells, degumming and leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

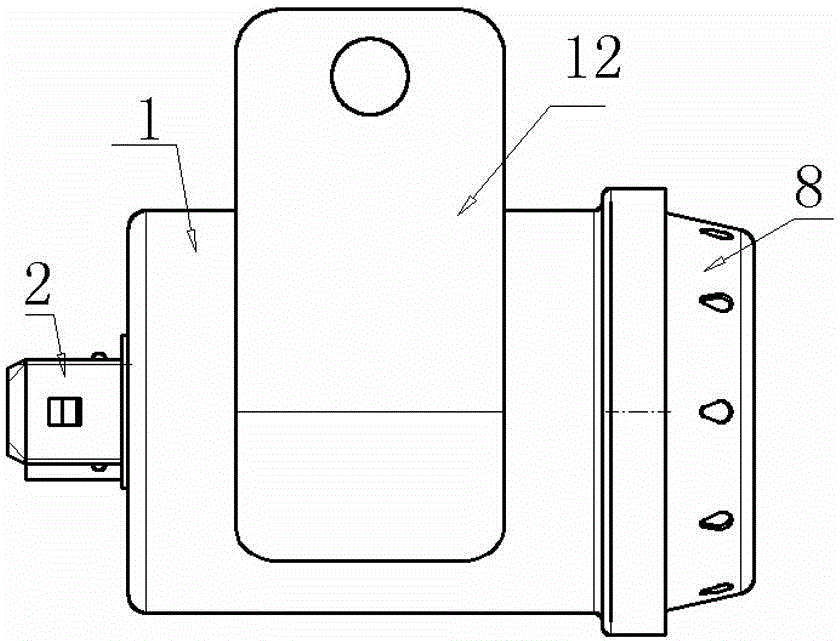

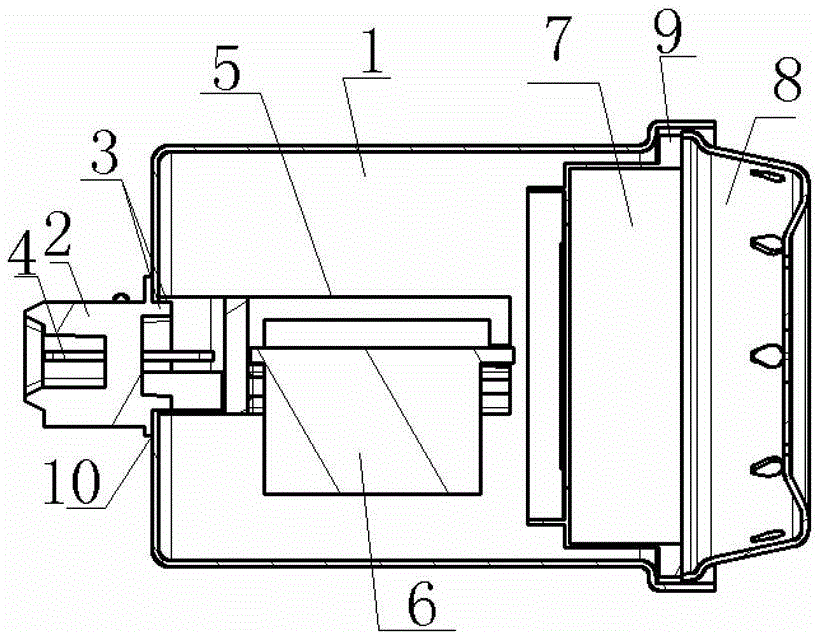

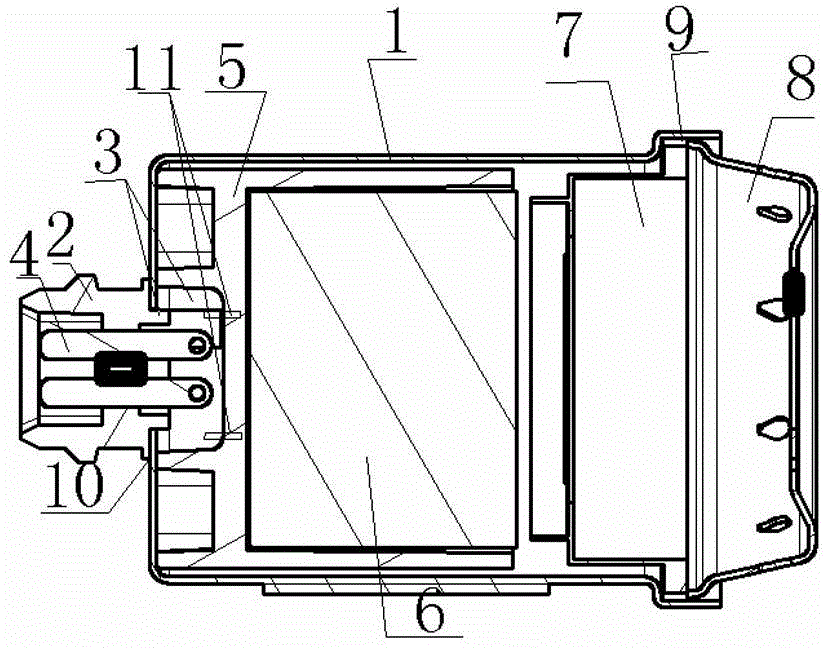

[0020] The present invention as figure 1 , 2 , 3, 4 shown.

[0021] The backup alarm assembly includes a shell 1, the tail of the shell 1 is provided with a socket, and a connector 2 is plugged into the socket, and a snap-in socket 3 is formed between the connector 2 and the socket, wherein The power pin 4 of the connector 2 is an embedded or injection-molded overall structure; the connector 2 is provided with a fixing seat 5 through a snap-in button 3 in the housing 1, and a circuit is arranged on the fixing seat 5 The control board 6 uses the fastener 12 to make the connector 2, the housing 1, and the fixing seat 5 into a whole; the power pin 4 is connected to the circuit control board 6 through the power line, and finally connected to the buzzer 7, which is sealed by sealing Circle 9 is also inlaid with outer cover 8.

[0022] The connector 2 is provided with a sealant or a sealing ring 10 on the end face of the socket.

[0023] The fixing base 5 is a "U"-shaped slot, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com