Small square soft sheet membrane module

A membrane module and film technology, applied in the field of small square film membrane modules, can solve the problems of unsatisfactory sewage treatment field, unfavorable product marketing, and difficulty in meeting daily processing capacity, etc., and achieves durable sealing, simple installation, and reduced The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

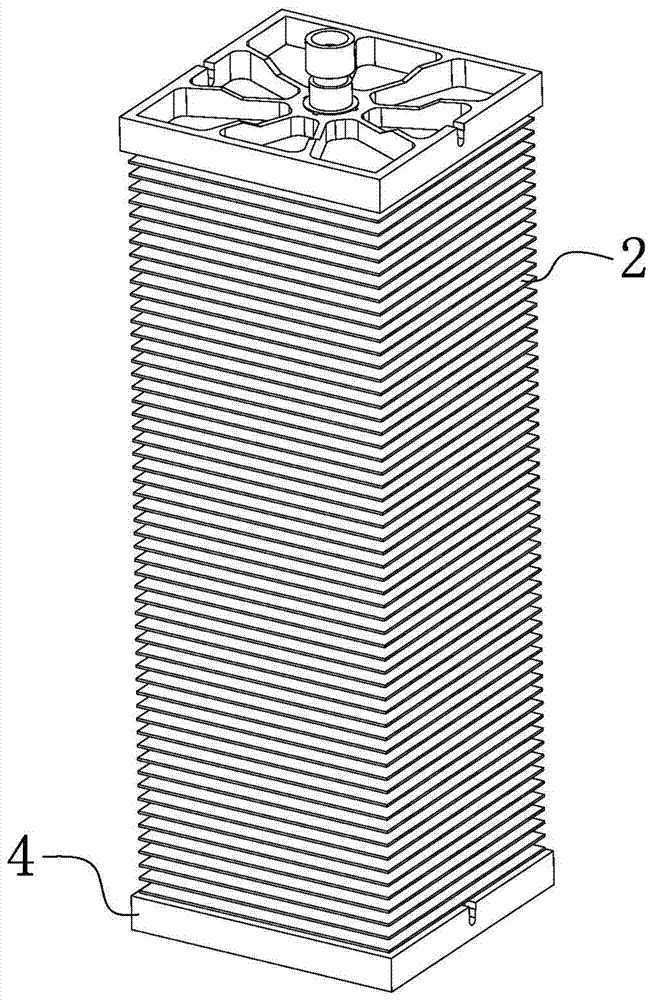

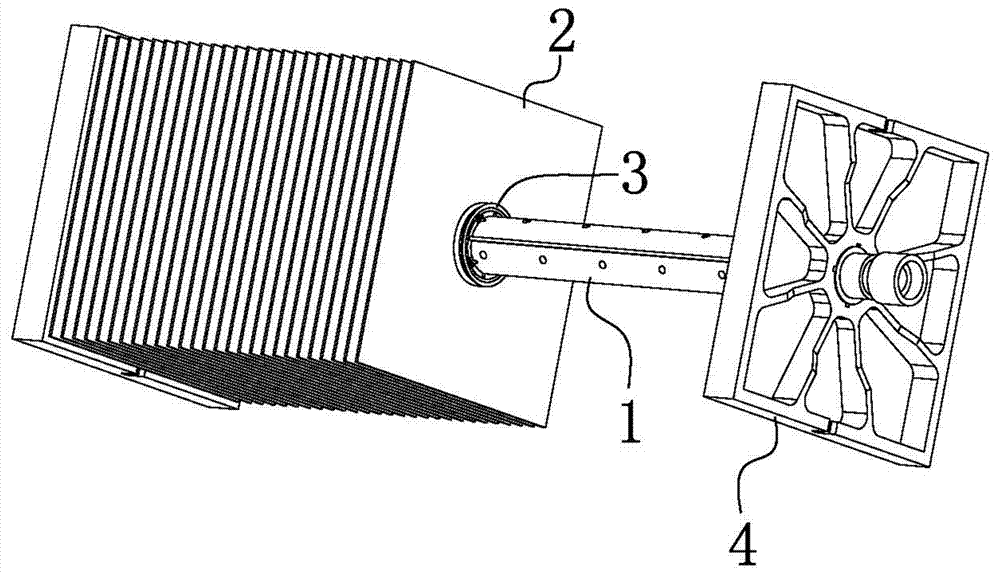

[0051] Embodiment 1: as Figure 1~Figure 7 As shown, a small square film membrane assembly includes a permeate water conduit 1 provided with a permeable hole 11, a soft film 2 and a locking piece 3 arranged on the permeate water conduit 1 interlaced, and the permeate water End plates 4 at both ends of the conduit 1;

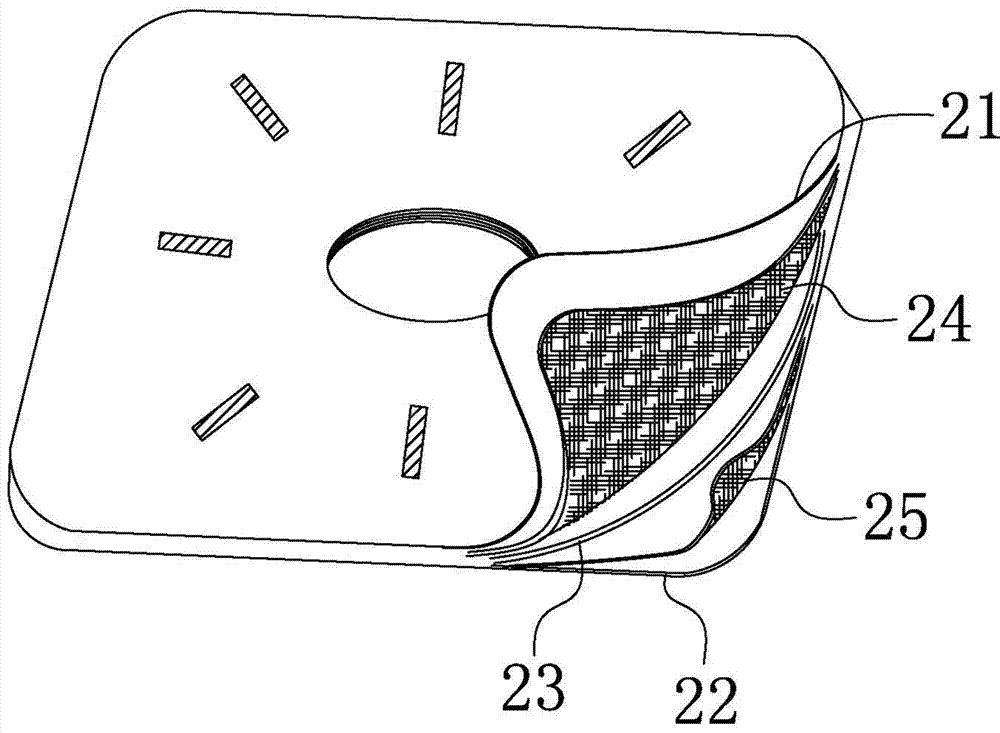

[0052] The soft film 2 includes a first diaphragm 21, a second diaphragm 22 and a supporting sheet 23 arranged between the first diaphragm 21 and the second diaphragm 22, the first diaphragm 21 and the second diaphragm 22 A first runner cloth 24 is arranged between the supporting sheets 23 , and a second runner cloth 25 is arranged between the second diaphragm 22 and the supporting sheet 23 .

[0053] The locking piece 3 is composed of an inner locking ring 31 close to the outer wall of the permeating water conduit 1, an outer locking ring 32 far away from the outer wall of the permeating water conduit 1, and an outer locking ring 32 disposed between the inner l...

Embodiment 2

[0057] Example 2: Reference Figure 1~Figure 7 , a small square film assembly, the difference from Embodiment 1 is that: the support sheet 23 of the film 2 is provided with a pressure regulating channel, and the film is provided with a joint at the pressure regulating channel, so The joint part is a part formed by ultrasonic welding of the first membrane, the second membrane, the first flow channel cloth and the second flow channel cloth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com