Hollow blade shaft-end sealing mechanism

A technology of shaft end sealing and hollow blades, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of loss of sealing performance, wear of moving and static plates, and short service life, so as to improve the sealing level, The effect of prolonging the sealing performance and securing the sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

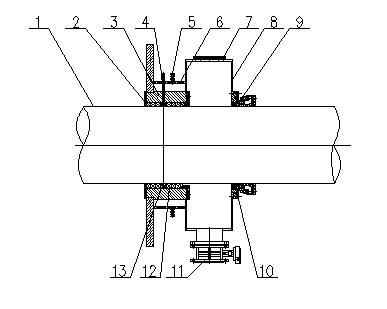

[0014] The present invention is sleeved on the circumferential outer surface of the main shaft 1, and includes: a bottom ring 2 and a packing seat 3 cooperating with the bottom ring 2, a number of packing seals 12 are arranged inside the packing seat 3, and the packing seals 12 are blocked by the bottom ring 2, The other end of the packing seat 3 is provided with a collection box 8;

[0015] A cooling jacket 6 is provided at the outer end of the packing seat 3 , and the packing seat 3 is provided with an air pipe 4 passing through the packing seat 3 and extending into the packing seat 3 .

[0016] A protective ring 13 is arranged between the packing seats 3 , and the air pipe 4 extends into the protective ring 13 .

[0017] The end of the collection box 8 is provided with a mechanical seal 9 .

[0018] A mirror port 7 is provided on the collecting box.

[0019] A dustproof ring 10 is provided at the end of the collection box 8 .

[0020] The shaft end sealing mechanism of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com