Internal high-pressure forming pushing and pressing device

A technology of pushing device and internal high pressure, applied in the field of internal high pressure forming and pushing device, can solve the problems of waste, waste of pipe materials, influence on demoulding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

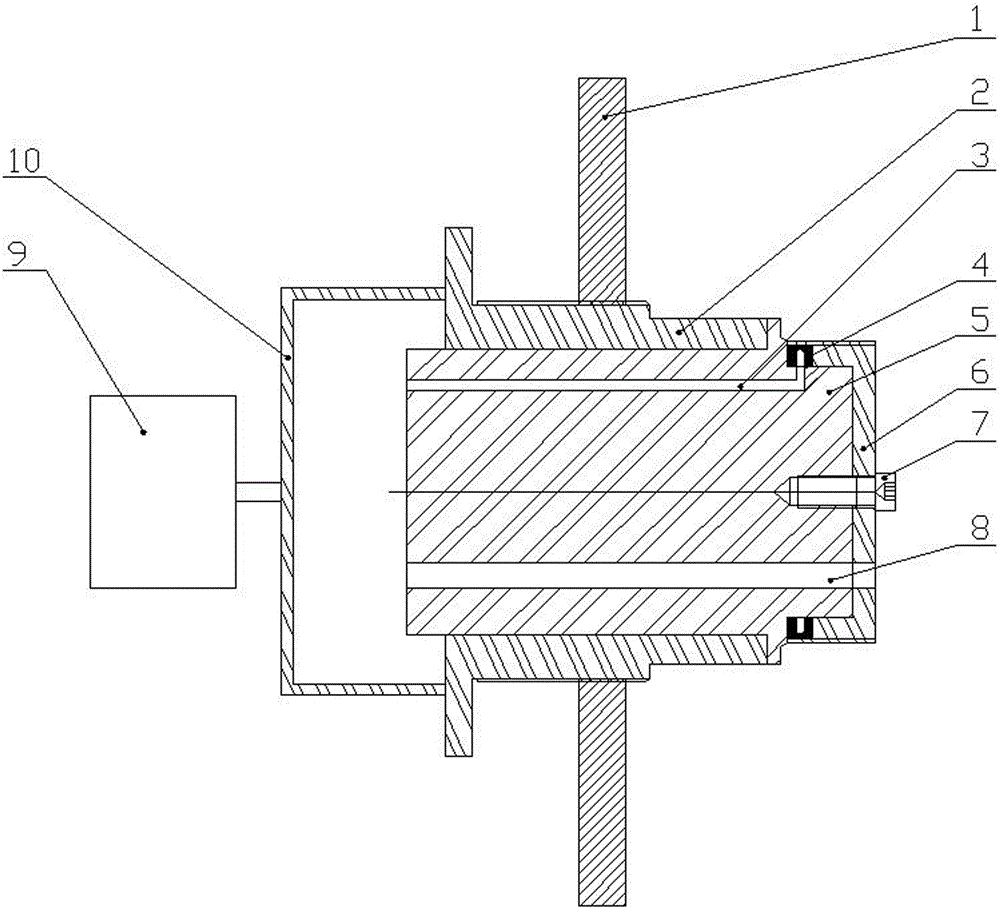

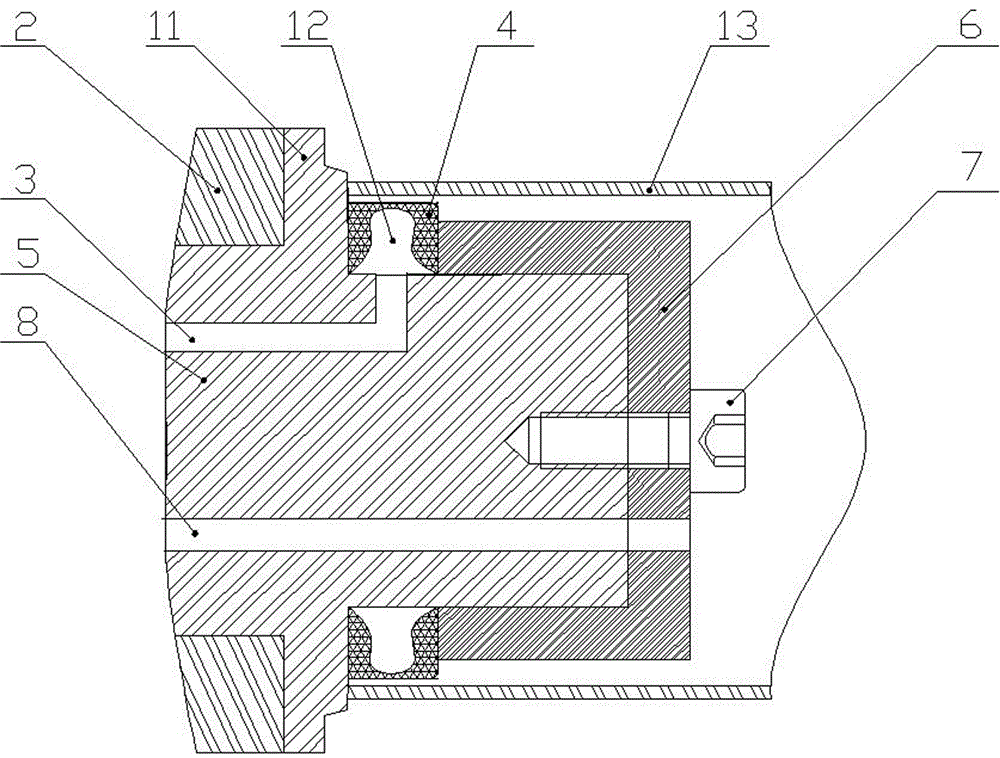

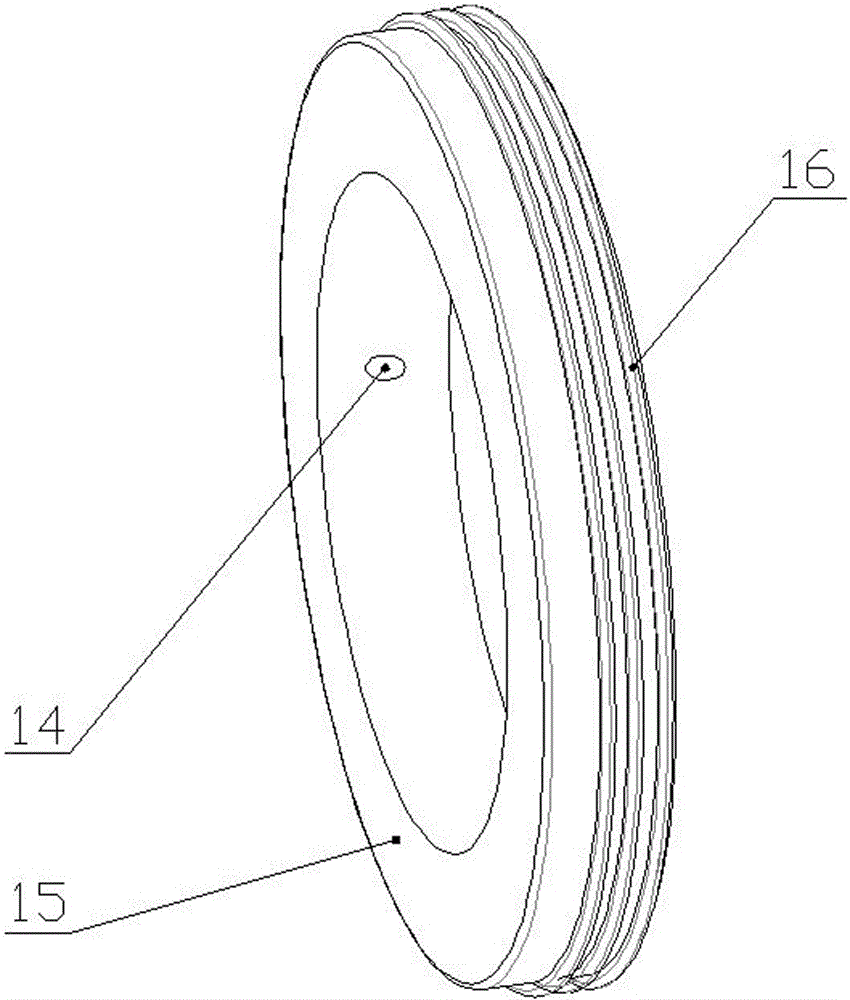

[0039] Refer to the attached Figure 1-4 , showing the relevant structure of the present invention in the form of a simplified diagram. exist figure 1 Among them, for the push head 2, according to the conventional understanding, it has the conventional reference system of the head end and the tail end, and the side where the head end is located in the head-to-tail direction is usually called the front side, while the side where the tail end is located is the rear side. side.

[0040] At the same time, for the push head assembly, since the tube blanks 13 of the internal high pressure forming device are all tube fittings, although they are not necessarily round tubes, they all have a nominal axis.

[0041] The end surface of the tube blank 13 is a pressure-bearing surface, which is fed by pushing the pusher 2, and the part to be formed is hydraulically formed based on the relatively high internal forming medium.

[0042] In view of this, an internal high-pressure forming push...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com