A kind of electric cutting tool

A cutting tool and electric technology, which is applied in the direction of manufacturing tools, shearing devices, metal processing equipment, etc., can solve the problems of cutting target fixing, etc., and achieve the effects of cutting accuracy, improving flatness, and fixing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

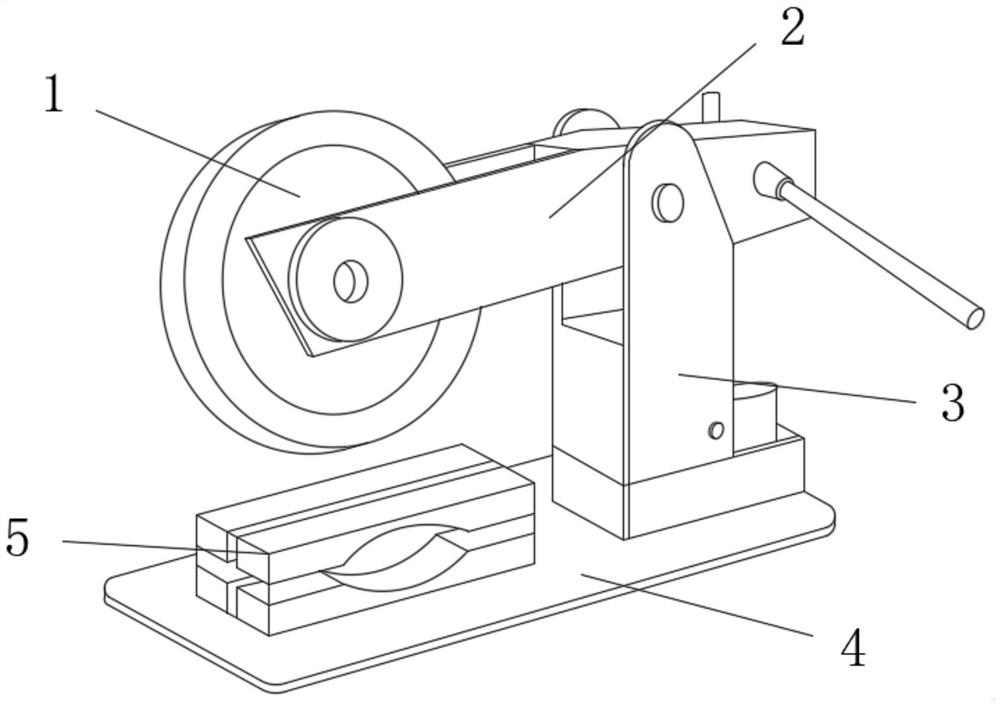

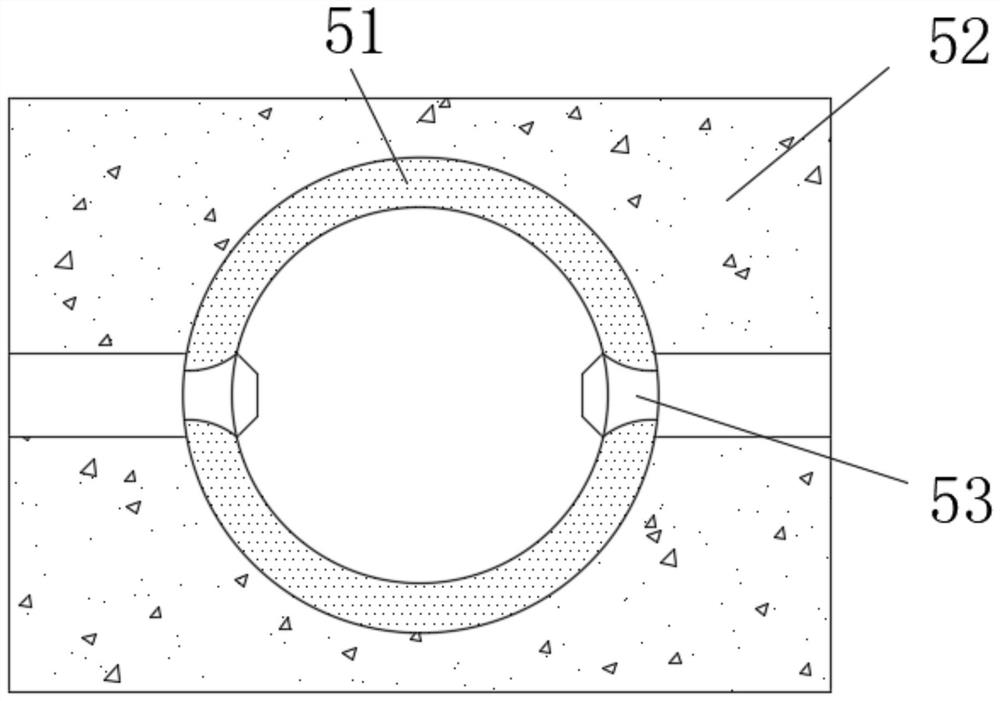

[0030] like Figure 1-3 As shown, the present invention provides a technical solution: an electric cutting tool, comprising a base plate 4, a support column 3 is fixedly connected to the right side of the upper surface of the base plate 4, and a pressing arm 2 is rotatably connected to the top of the support column, A cutting disc 1 is rotatably connected to the left end of the pressing arm 2, and a fixing device 5 is fixedly connected to the upper surface of the bottom plate 4. The fixing device 5 is arranged directly below the cutting disc 1, and the fixing device 5 includes a fixing block. 52. The number of the fixing blocks 52 is two, and the two fixing blocks 52 are stacked on top of each other. It is characterized in that: the depressions on the opposite surfaces of the fixing blocks 52 are fixedly connected with a squeeze bag 51. , the left and right ends of the squeeze bag 51 are movably connected with a pressure device 53, the left and right ends of the squeeze bag 51...

Embodiment 2

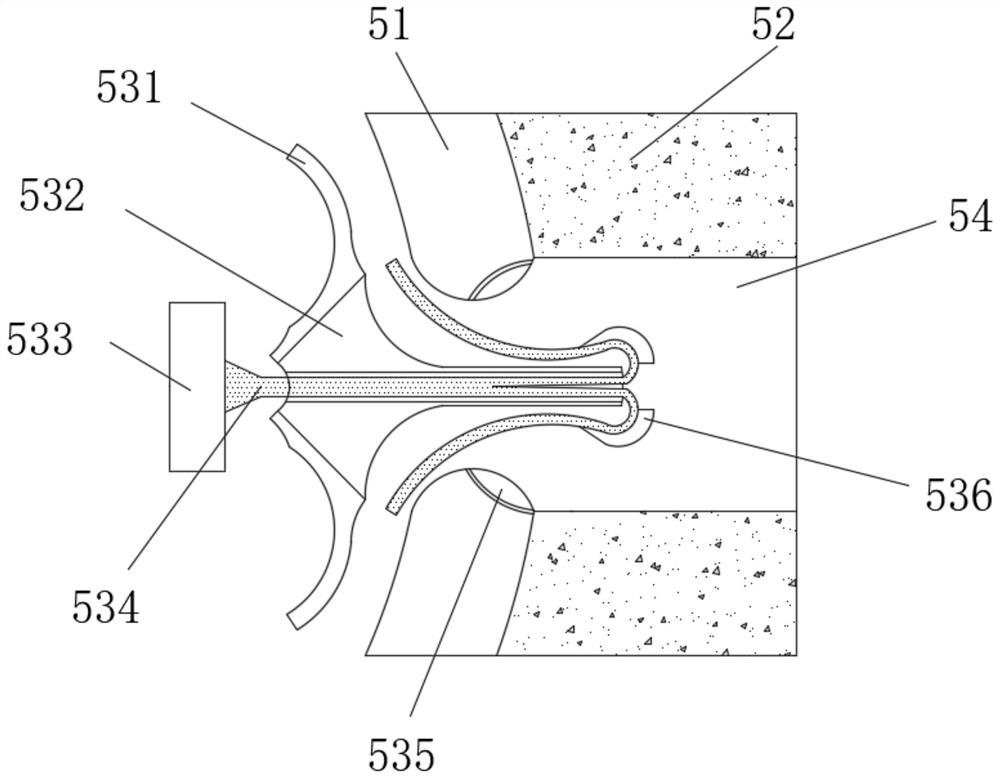

[0033] like Figure 4-6 As shown, on the basis of the first embodiment, the present invention provides a technical solution: the blocking device 536 includes a rubber casing 5363 and an elastic rubber block 5361, and the rubber casing 5363 and the elastic rubber block 5361 are both fixedly connected to the special-shaped On the surface of the elastic iron rod 534, the elastic rubber block 5361 is fixedly connected to the inside of the rubber shell 5363, the outer surface of the elastic rubber block 5361 is provided with a groove 5364, and the surface of the rubber shell 5363 is fixedly connected with a locking device 5362, and the locking devices 5362 are symmetrically arranged at both ends of the groove 5364, and the special-shaped elastic iron rod 534 moves to the right side, so that the special-shaped elastic iron rod 534 flattens and contracts the elastic rubber block 5361, so that the space in the groove 5364 becomes larger , when the blocking device 536 contacts the sque...

Embodiment 3

[0037] like Figure 7 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the docking device 533 includes a docking block 5332, a sliding rod 5333 and a pressing block 5335. The left end of the elastic iron rod 534 is fixedly connected. The docking block 5332 is provided with a sliding hole 5331. The sliding rod 5333 penetrates the docking block 5332 through the sliding hole 5331 and extends to the upper and lower ends of the left side. Both are rotatably connected with a rotating shaft 5336, the upper end of the sliding rod 5333 is rotatably connected with the upper end of the pressure block 5335 through the rotating shaft 5336, and the upper end of the sliding rod 5333 is fixedly connected with the pressure block 5335 through the elastic block 5334, the said The number of pressing blocks 5335 is three, and the pressing blocks 5335 are rotatably connected to each other by the rotating shaft 5336 and the elastic block 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com