Sealing inspection well socket

A technology for checking wells and sealing, which is applied in waterway systems, drainage structures, water supply devices, etc. It can solve the problems of inconvenient maintenance and replacement of sealing devices, and the inability of sealing connection devices to achieve good sealing effects, etc., to achieve convenient operation and strengthen sealing The effect of strong resistance and sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

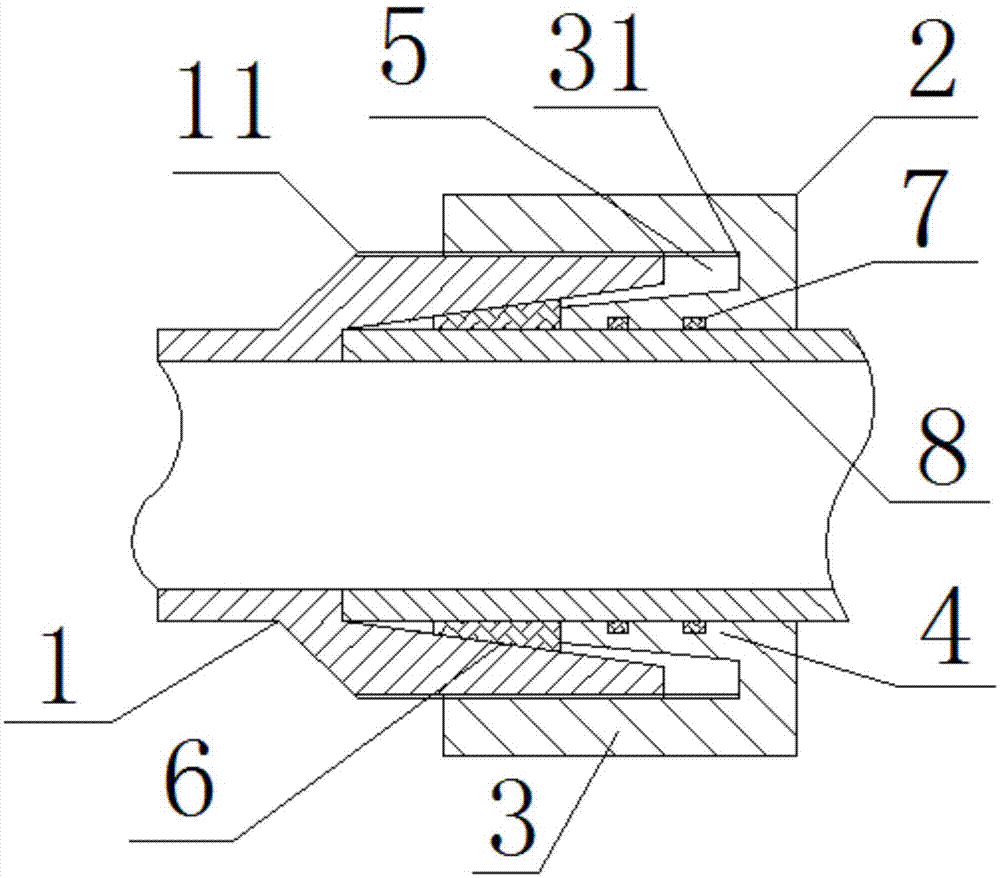

[0024] The technical solutions of the present invention will be further specifically described below in conjunction with the accompanying drawings and specific embodiments.

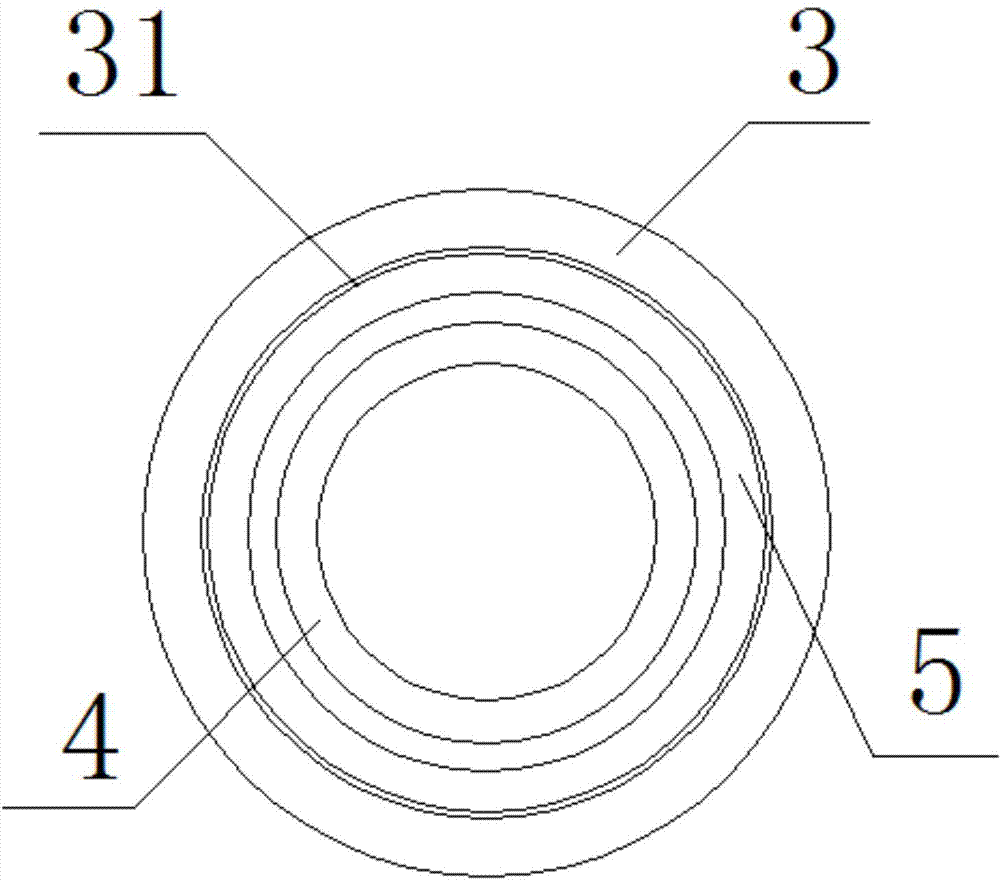

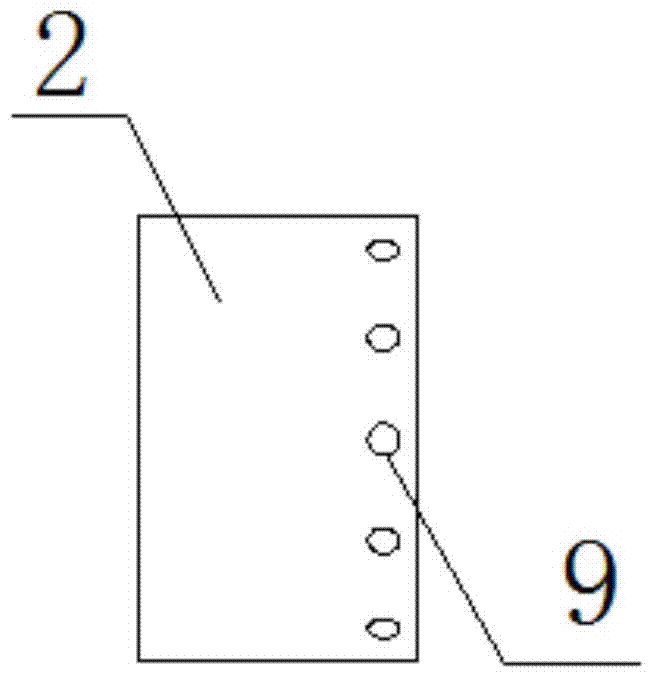

[0025] combine Figure 1~3 , a sealing inspection well socket of the present invention includes a socket, and the socket includes a fixed socket 1 and a detachable socket 2, and the detachable socket 2 is composed of an outer sleeve 3, an inner sleeve 4, and a gap between the inner sleeve and the outer sleeve. The formed annular groove 5 is formed, the outer wall of the fixed socket 1 is provided with an external thread 11, the inner wall of the outer sleeve 3 is provided with an internal thread 31 corresponding to the external thread 11, and the inner diameter of the fixed socket 1 is larger than that of the inner sleeve 4 the outer diameter. In addition, the section of the fixed socket 1 is wedge-shaped with gradually decreasing inner diameter from the outside to the inside, the section of the inner sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com