Pressurizing pilot-operated type high-temperature and high-pressure labyrinth valve

A high-temperature, high-pressure, pilot-operated technology, applied in the direction of valve lift, valve details, valve devices, etc., can solve the problems of reducing the unbalanced force of the medium, high sealing level of the valve seat, and few decompression stages, so as to ensure the adjustment accuracy and Reliability, improvement of valve sealing level, space and cost saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

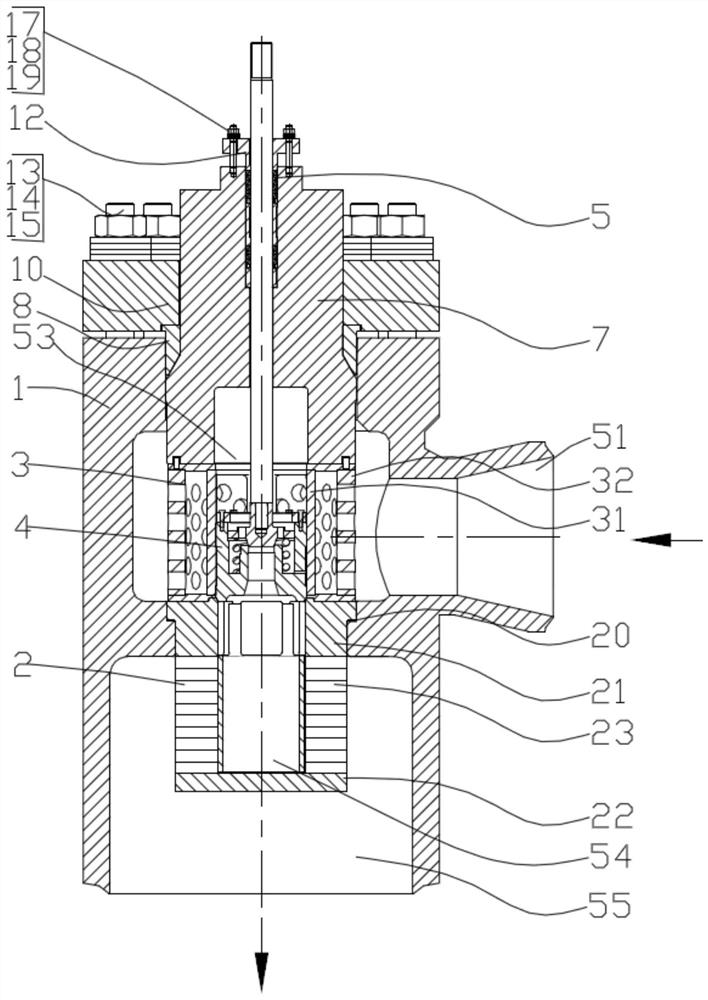

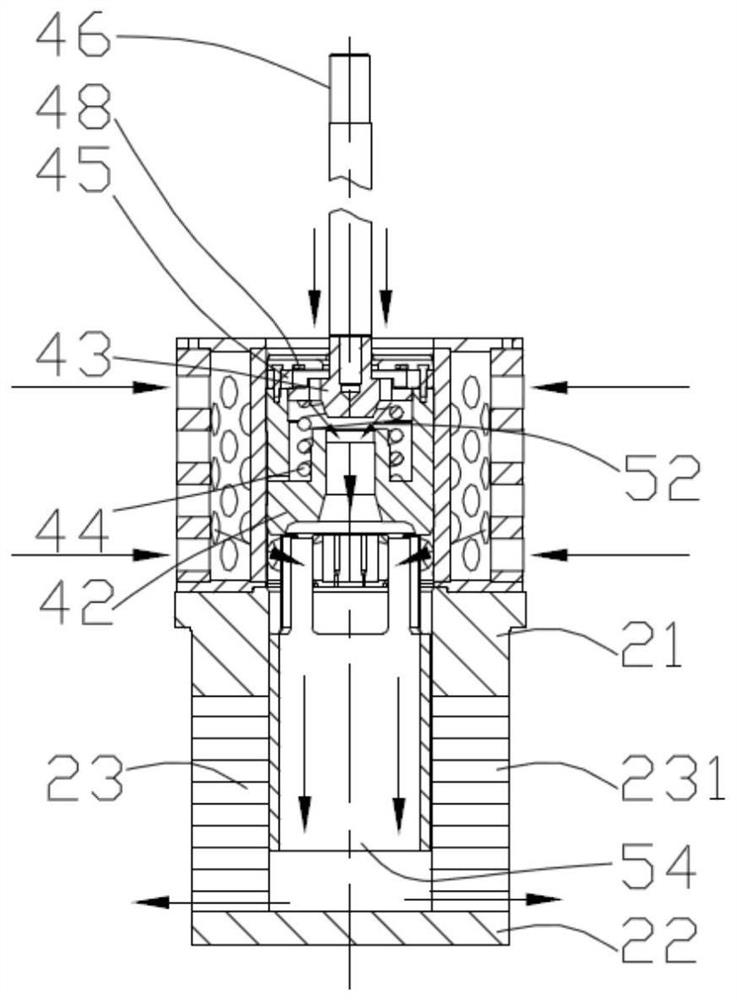

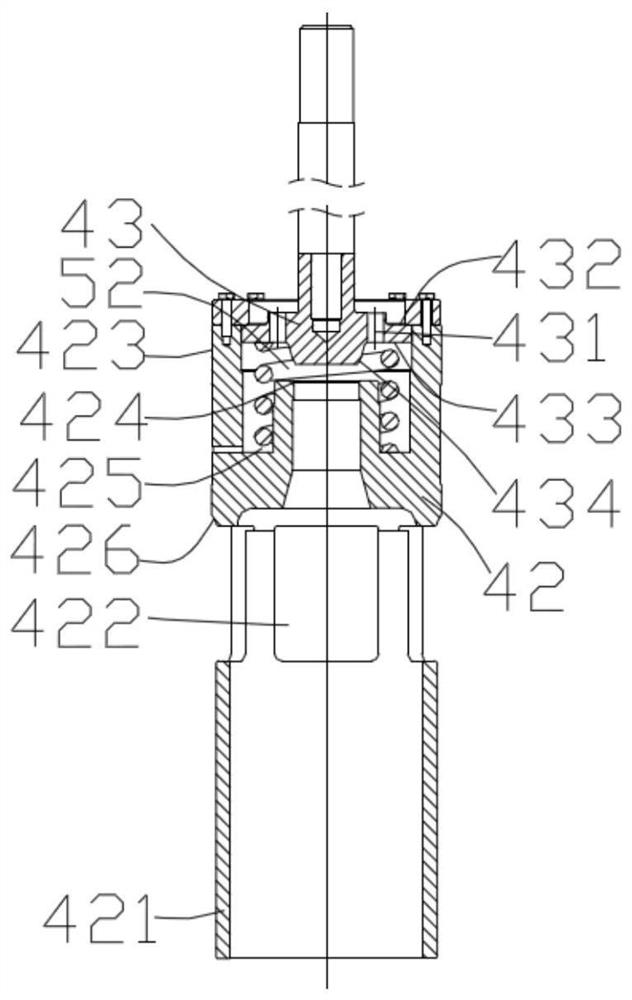

[0063] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0064] like figure 1 As shown, a pressure-charging pilot-operated high-temperature and high-pressure labyrinth valve of the present invention includes a valve body 1, and an integrated labyrinth combined valve seat assembly 2 is placed in the valve body 1, and the valve body 1 and the integrated labyrinth combined valve seat assembly 2 are installed. There are winding pads 20;

[0065] The flow equalizing sleeve 3 is placed on the integrated labyrinth combined valve seat assembly 2;

[0066] The stuffing box 7 is placed on the flow equalizing sleeve 3;

[0067] The self-sealing ring 8 is placed between the valve body 1 and the stuffing box 7;

[0068] The middle flange 10 is placed on the self-sealing ring 8, and is fastened to the valve body 1 by bolts 13, nuts 14, disc springs 15;

[0069] One end of the valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com