Cascading valve clack type adjusting valve

A technology of regulating valve and valve disc, which is applied in valve details, lift valve, parts contacting between valve elements and valve seat, etc. The effect of improving the sealing level of the valve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

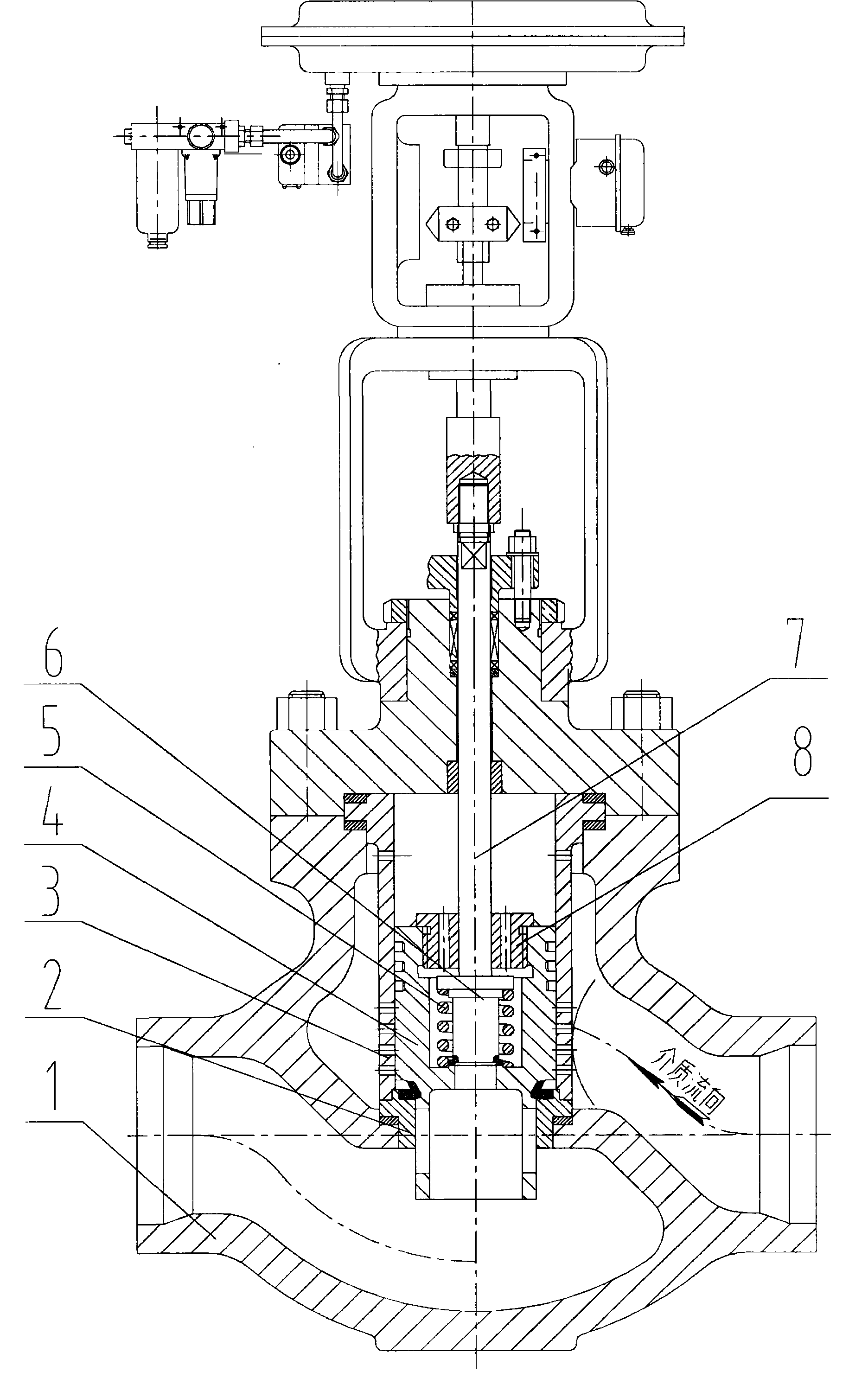

[0013] In the embodiment shown in the figure, the center of the valve disc 4 is drilled with an inner flow channel hole, and the upper part is processed with a sealing surface. The valve stem 7 and the auxiliary valve disc 6 are of an integrated structure. The valve disc 4 and the spring 5 pass through the valve disc gland 8 Connect with valve stem 7. When the valve is closed, the valve stem 7 compresses the spring 5, the auxiliary disc 6 presses the inner sealing surface of the valve disc 4, and the lower sealing surface of the valve disc 4 presses the sealing surface of the valve seat 2 to realize the sealing of the two sealing surfaces, and the valve disc 4 becomes non-contact. Balanced structure; when the valve is opened, the auxiliary valve disc 6 is opened first, the upper and lower chambers of the valve disc 4 are connected, the valve disc 4 becomes a balanced structure, and the valve stem 7 drives the valve disc 4 to move up and down through the valve disc gland 8 and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com