Device assembly for horizontal well temporary well plugging operation through coiled tubings and use method

An operation device and technology for horizontal wells, which are applied in wellbore/well components, drill pipes, casings, etc., can solve the problems of high well control safety risks, complicated operation procedures, and long construction periods, so as to reduce the process complexity, The effect of reducing well control safety risks and shortening construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

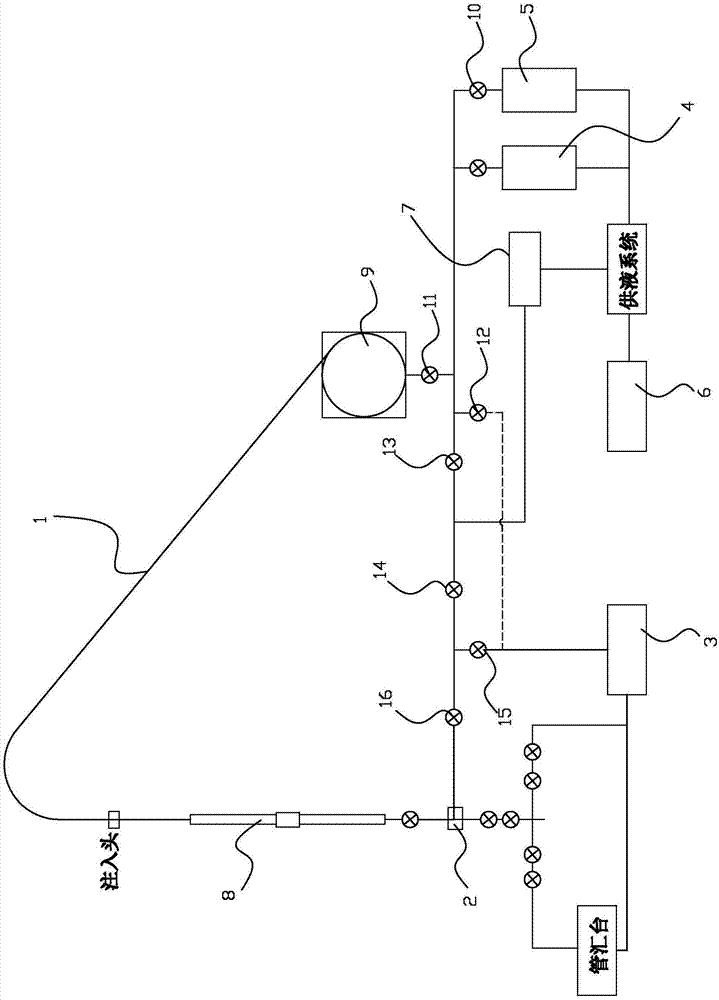

[0025] The coiled tubing is used to integrate the temporary well sealing operation devices of horizontal wells. The integrated devices mainly include coiled tubing vehicles, single-machine cementing vehicles or double-machine cementing vehicles. The operation procedures of temporary well sealing include drilling, lowering bridge plugs, and continuous cement injection plugs and reverse circulation well washing process, the coiled tubing vehicle includes a headstock, a control cabinet, a power system, a drum, a 2-inch coiled tubing, a 2.375-inch coiled tubing 1 and an injection head connected to the 2.375-inch coiled tubing 1 and corresponding accessories, the A single-machine cementing vehicle or a double-machine cementing vehicle includes a headstock, a power system, an instrument control system and a metering liquid tank.

[0026] The device integration process of the well opening and bridge plugging process is that the liquid tank 6 leads to the fracturing vehicle 7 and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com