Method for using gel foaming agent for suppressing bottom water coning of heavy oil thermal recovery

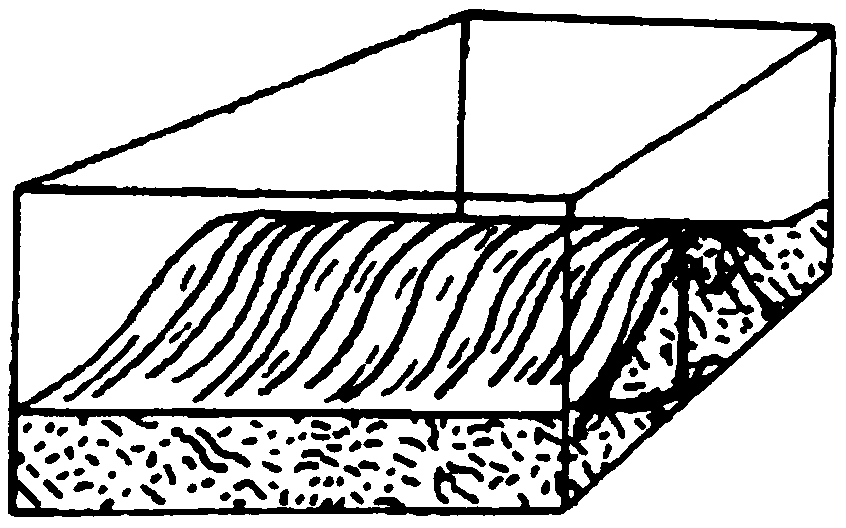

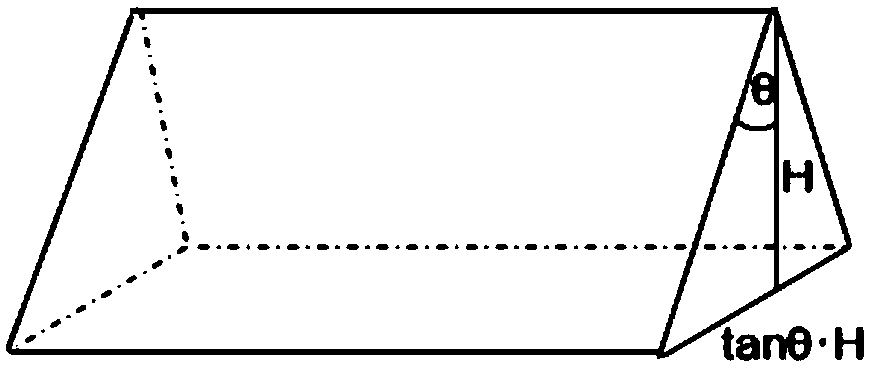

一种凝胶泡沫、稠油热采的技术,应用在凝胶泡沫剂领域,能够解决降低水平井含水率、无法使用颗粒性堵剂、封堵底水等问题,达到提高蒸汽波及系数及利用率、改善开发效果、延缓锥进速度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 1. Basic situation of oil wells

[0048] Measure Well Chun 10Ⅱ2-9-3H is a horizontal oil production well in the eastern Junggar Basin. The drilling completion layer is the Ⅱ2 sublayer of the first member of the Shawan Formation. N 1 S 1 II 2 Sand roof): the oblique depth is 1066.00m, the vertical depth is 960.41m, and the horizontal displacement is 195.19m.

[0049] 2. Design idea and water shutoff parameter design

[0050] Design ideas:

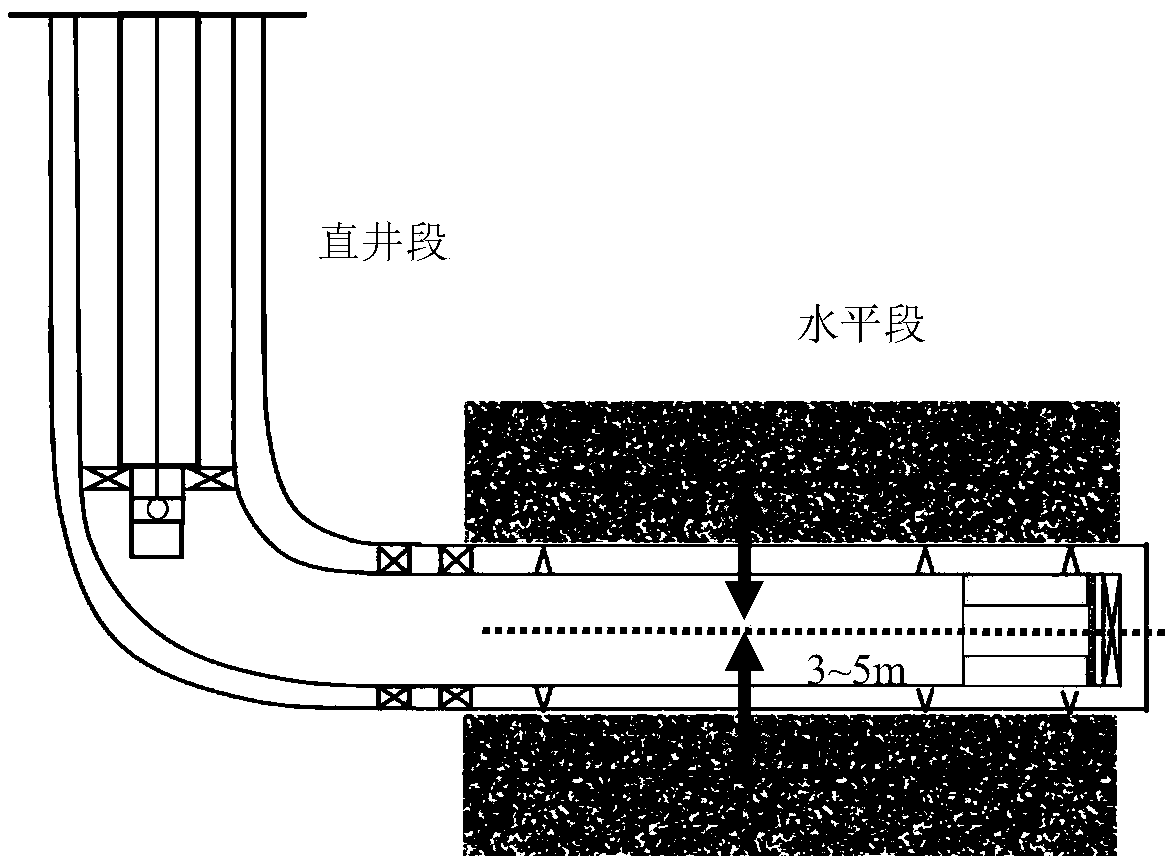

[0051] Using gel foam water blocking technology, the design idea is to use three slugs: front slug, main body slug and replacement slug. The front slug mainly uses nitrogen, which pushes the water in the wellbore and the formation near the wellbore to the oil layer, and at the same time balances the formation pressure; the main slug injects nitrogen and gel foam agent to form a nitrogen-gel foam section in the water channeling channel plug to suppress bottom water intrusion; the replacement slug is a nitrogen slug, which mainly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com