Apparatus for producing plastic parts interspersed with reinforcing fibres

A technology of plastic parts, reinforcing fibers, used in mixers, fluid mixers, transportation and packaging, etc., can solve problems such as unusable clean pistons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

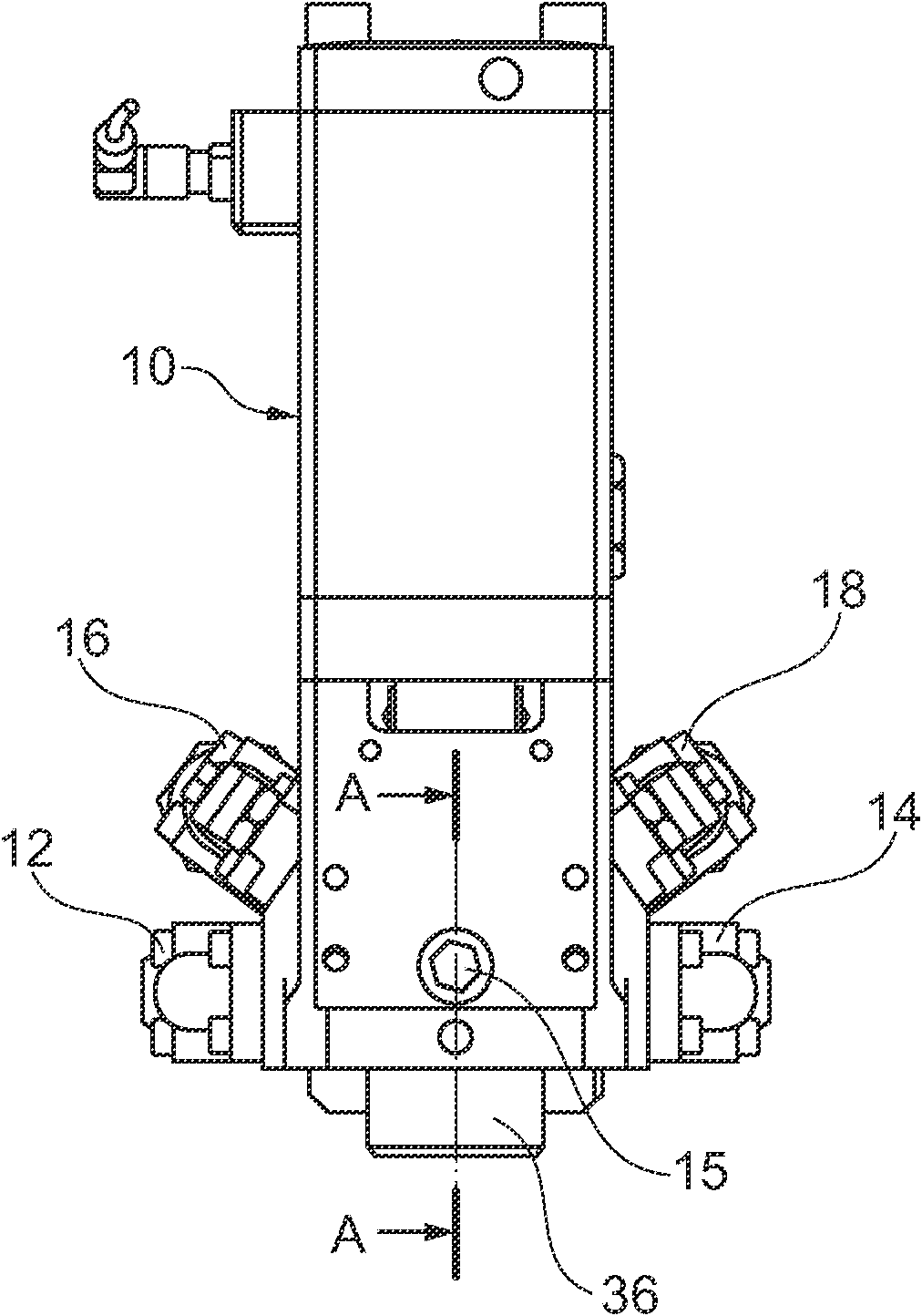

[0022] exist figure 1 A schematic front view of a mixing head 10 with a corresponding housing and two material supply lines 12 and 14 and two material recirculation lines 16 and 18 is shown in . At the lower end of the mixing head 10 can be seen an outlet duct 36 from which the mixture of fibers and reaction components exits, as will be described below.

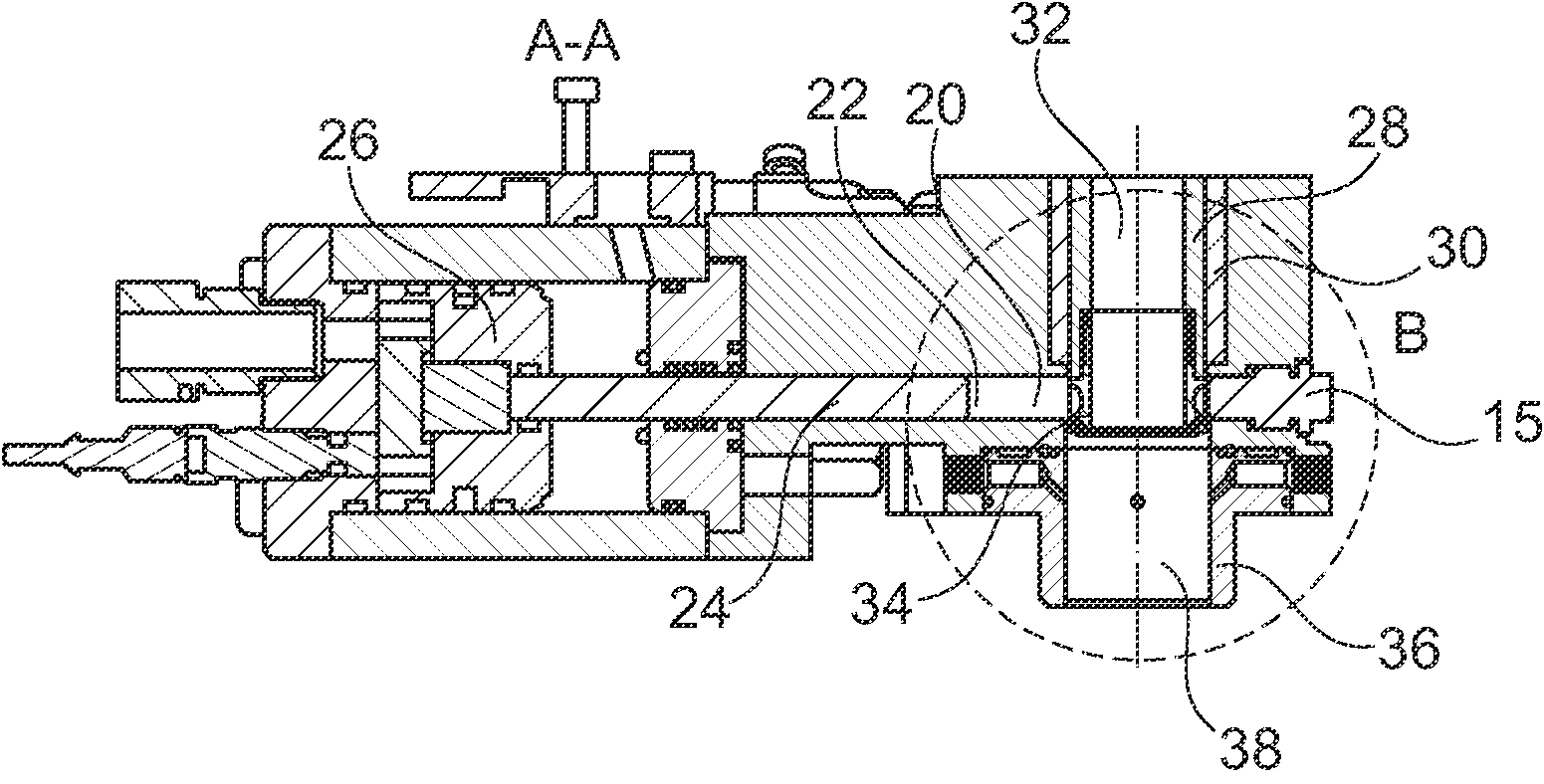

[0023] exist figure 2 shown in figure 1 A sectional view of the lower portion of the mixing head shown along the line A-A. In this case, the mixing head 10 has, in a bore of its housing, a bushing 30 in which the cleaning piston 28 is guided so as to be movable back and forth. Both the bushing 30 and the cleaning piston are only partially shown here (the respective lower region). A fiber feed channel 32 of circular cross-section is formed in the interior of the cleaning piston 28 and extends coaxially to the housing bore.

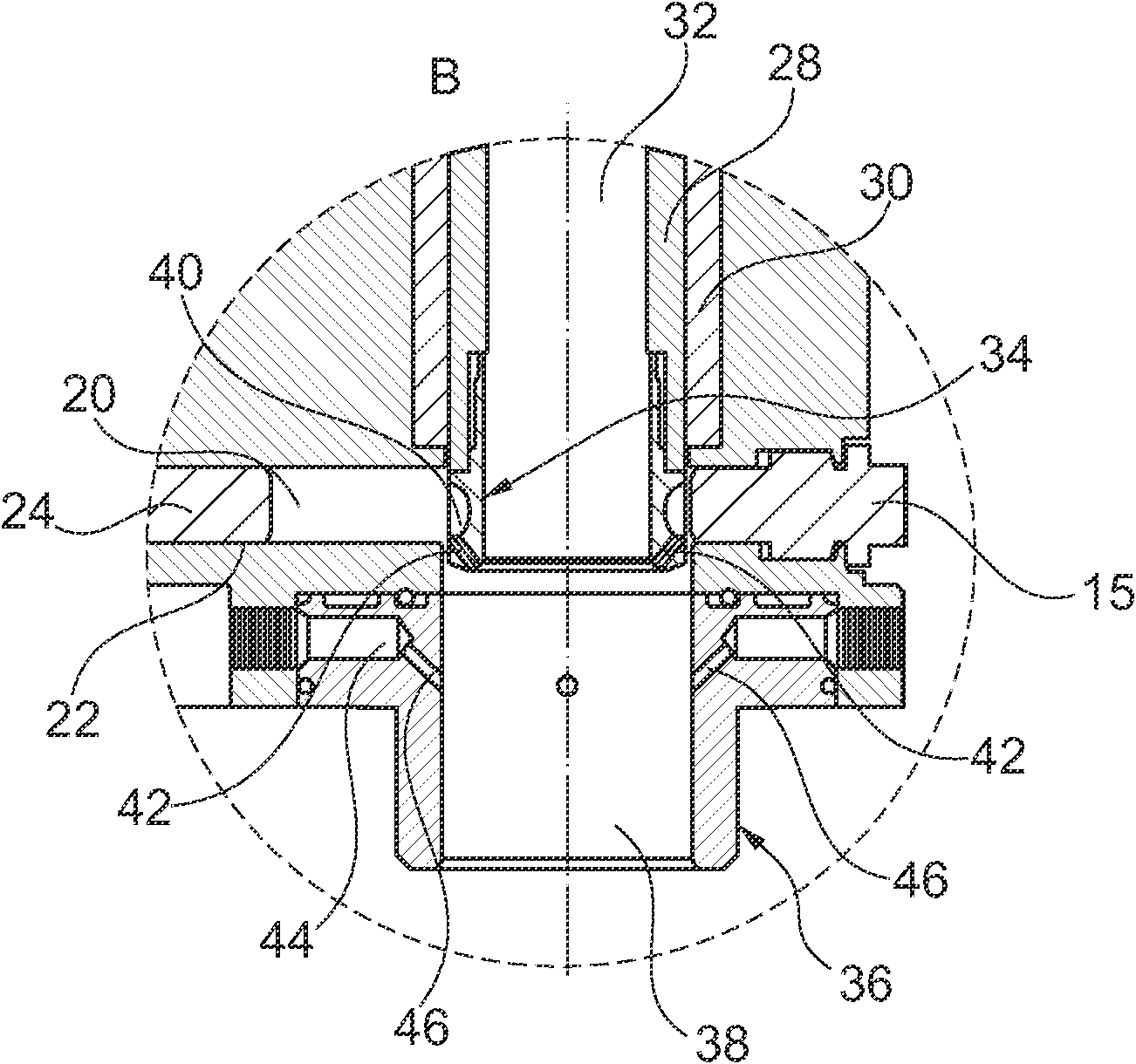

[0024] The fiber feed channel 32 of the cleaning piston 28 opens into a coaxial cylindrical outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com