Ultralow-frequency resin tapping method

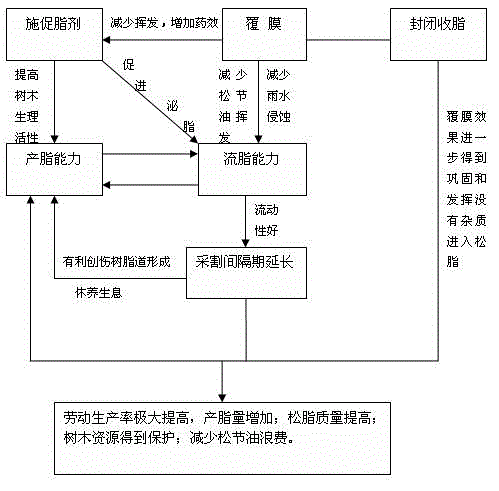

An ultra-low frequency, fat extraction technology, applied in forestry, application, agriculture, etc., can solve the problems of polluting turpentine quality, affecting product quality, increasing costs, etc., to achieve the effect of reducing turpentine evaporation, improving labor productivity, and increasing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific embodiment:

[0026] A method for ultra-low frequency fat extraction, the method comprising the steps of:

[0027] 1. Prefabricated scraping surface: scrape off the rough bark on the sunny side of the trunk with fewer scars, and make a scraping surface for opening the middle and side grooves;

[0028] 2. Set the middle groove: Open the middle groove in the middle of the scraping surface. The middle groove is the flow channel for the collection of turpentine. It is about 20-25 cm long and 1.5-2 cm wide. The groove is wide on the outside and narrow on the inside, straight and smooth;

[0029] 3. Install the grease guide and grease receiver: slightly flatten the two sides of the end of the middle ditch, and build a nail seat for the grease receiving bag. The surface of the nail seat is slightly higher than the surface of the middle groove, and wood chips, paper chips or plastics can be used....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com