Method for manufacturing toilet table top of mobile holiday house

A manufacturing method and toilet technology, which can be applied to indoor sanitary piping devices, components of lighting devices, semiconductor devices of light-emitting elements, etc., and can solve problems such as large spaces, easy cracks, and high water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

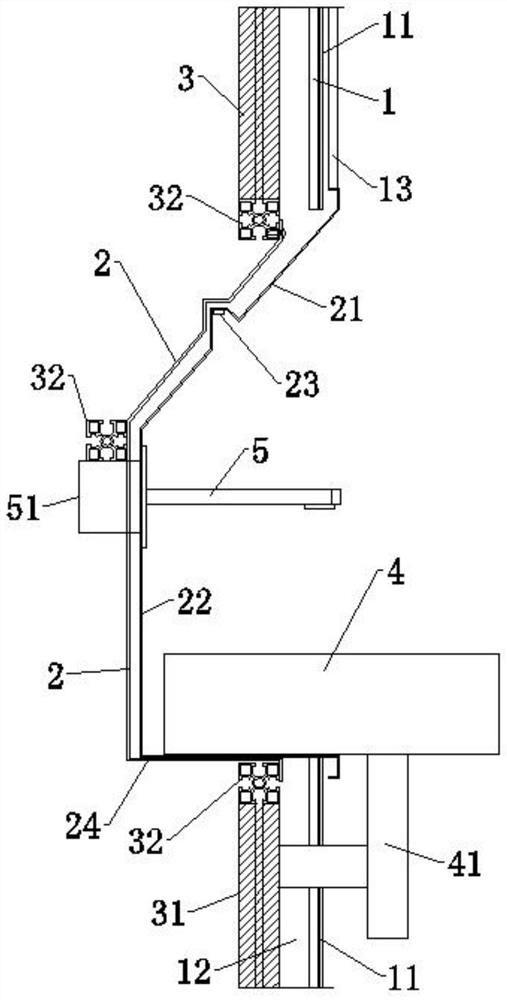

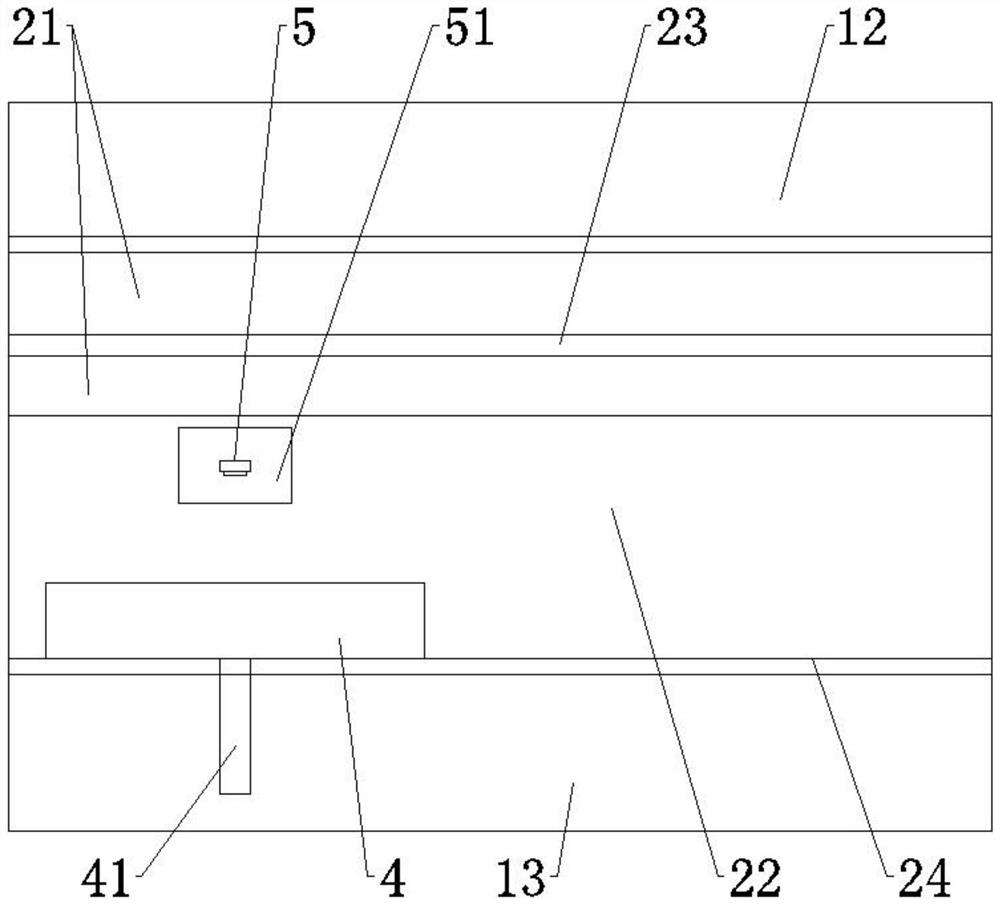

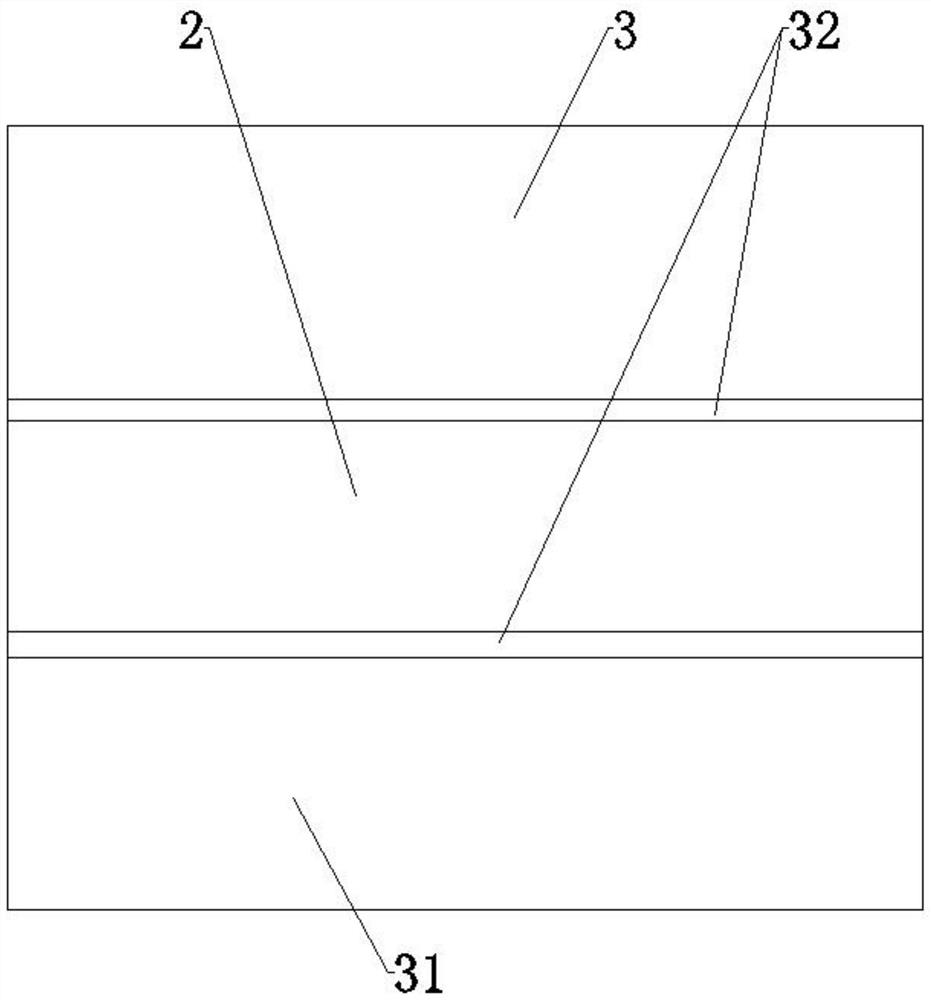

[0030] see Figures 1 to 6 As shown, the present invention provides a technical solution: a method for manufacturing a bathroom countertop for a mobile holiday home, comprising the following steps:

[0031] Step 1, a plurality of profile skeletons 32 are fixedly erected between the equipment room 62 and the living room 6 in the mobile vacation home, and the profile skeletons 32 are built into a vertical frame structure, and the equipment room is formed by the frame structure formed by the profile skeletons 32. 62 is separated from the living room 6, and the upper insulation board 3 and the bottom insulation board 31 are installed on the equipment room 62 side of the profile skeleton 32, and the upper insulation board 3 and the bottom insulation board 31 are vertically fixed on the profile skeleton 32 on the frame structure, the upper insulation board 3 and the bottom insulation board 31 are arranged at a certain distance;

[0032] Step 2, install the upper leveling wall surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com