Tightly-propping pulling type detaching device for bearing neck bush

A technology for dismantling device and inner bushing, applied in the directions of hand-held tools, manufacturing tools, etc., can solve the problems of low work efficiency, damage to the body structure and bearing inner bushing 9, difficulty, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

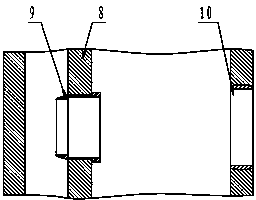

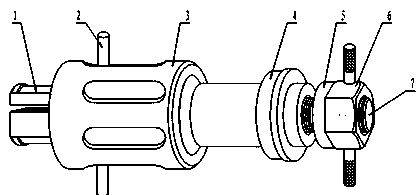

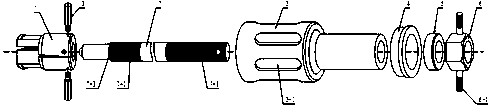

[0022] See Figure 2, image 3 , the present invention includes a stretching sleeve 1, a guide support sleeve 3, an annular support seat 4, a pressure plate 5, a rotating nut assembly 6 and a pull rod 7, and the stretching sleeve 1 is a split-type hinged structure, which is assembled with the left end of the pull rod 7 , the right end of the pull rod 7 is assembled with the rotating nut assembly 6, and the guide support sleeve 3, the ring support seat 4 and the pressure plate 5 are sequentially set on the outside of the pull rod 7 from left to right, and the ring support seat 4 is connected with the bearing hole of the body 10 outfits.

[0023] see Figure 4 ~ Figure 7 , the tensioning sleeve 1 of the present invention includes an upper tensioning sleeve 1-1 and a lower tensioning sleeve 1-2, and the upper tensioning sleeve 1-1 and the lower tensioning sleeve 1-2 are hinged through a pin assembly 1-3 , on the left end of the outer wall of the upper tension sleeve 1-1, an uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com