Shrinkage fitting tool device for stator core of shielded motor

A stator core and shielded motor technology, applied in the manufacture of the stator/rotor body, etc., can solve the problems of insufficient lifting points, core accuracy and strength damage, etc., and achieve the effect of ensuring hot-fitting work, easy operation, and satisfying precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

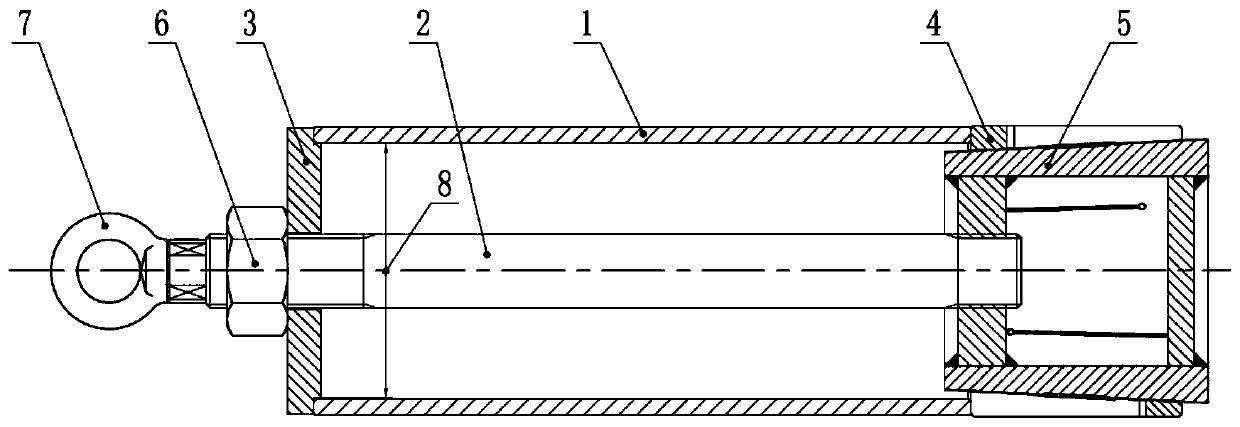

[0011] Such as figure 1 The tooling device shown is composed of a pressing device, a force applying device, a hoisting device and a tensioning device. The shape of the pressing device is an overall elongated cylinder 1, and the inner circle at one end of the cylinder 1 has a matching stop 8, and the matching stop The mouth 8 is matched with the outer diameter of the pressure plate 3 in the force applying device, and the end face on the other side of the cylinder 1 is pressed against the expansion ring 4 of the tensioning device. 6. The joint is connected into a whole, and one end of the double-ended stud 2 is threaded and tightened on the cone 5 of the tensioning device. After the outer circular seam of the pressure plate 3 and the inner circular seam of the cylinder 1 cooperate with each other, the cylinder 1 is set On the double-ended stud 2, the nut 6 and the thread on the other end of the double-ended stud 2 are screwed together to assemble the various parts; in the threa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com