Loader for municipal engineering

A loader and engineering technology, applied in the direction of earth mover/shovel, mechanically driven excavator/dredger, construction, etc., can solve the problems of inconvenient movement, low work efficiency, easy overheating, etc., and achieve excellent reduction. The effect of shock-absorbing performance, high work efficiency, high mechanical strength and tear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

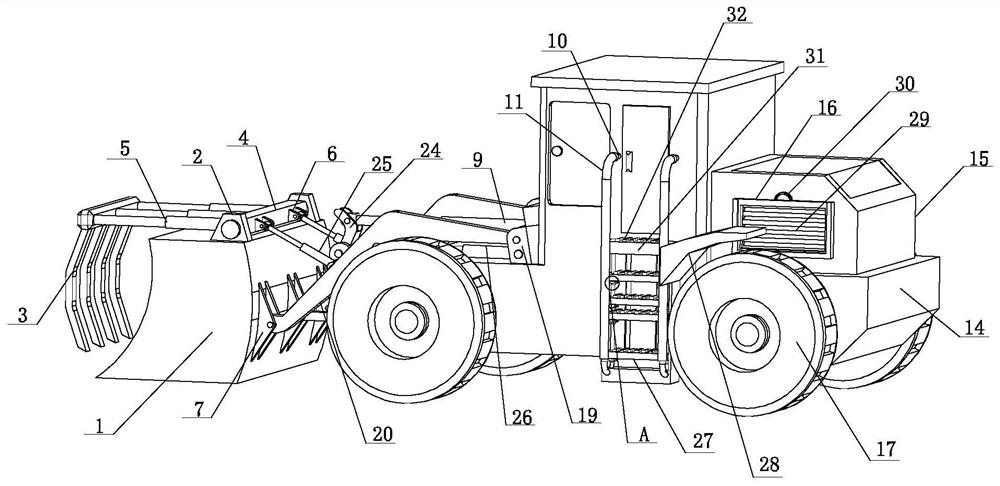

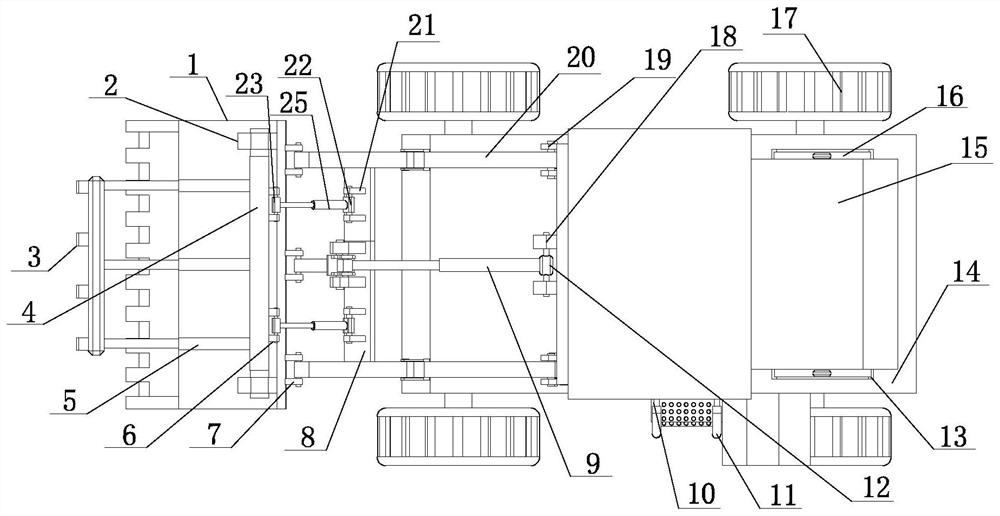

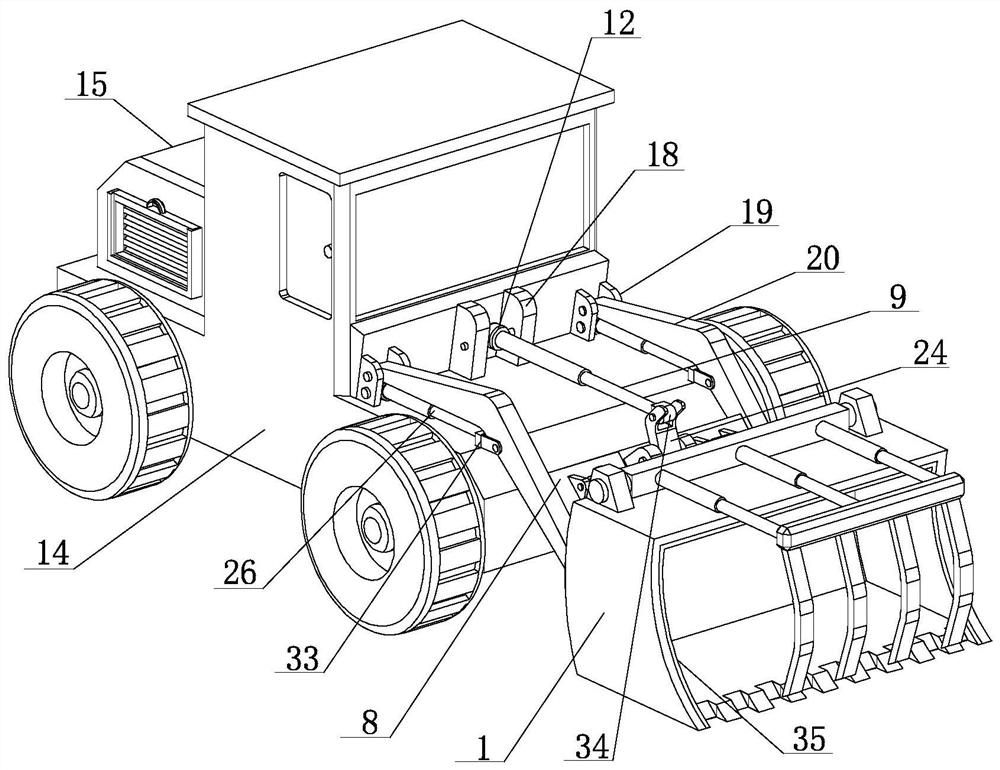

[0032] see Figure 1-10 , the present invention provides a technical solution: a loader for municipal engineering, comprising a vehicle body 14, a first telescopic rod 5, a mechanical arm 20 and a bucket 1, and the inner wall of the vehicle body 14 is fixedly connected with four identical Wheels 17, two fifth fixed mounts 19 are fixedly connected to one side of the top of the vehicle body 14, and a fourth fixed mount 18 is fixedly connected to the top of the vehicle body 14, and the fourth fixed mount 18 is located between the two fifth fixed mounts 19. The other side of the top of 14 is fixedly connected with a box body 15, the inner wall of the fourth fixed frame 18 is fixedly connected with the second connecting block 12 through the rotating shaft provided, and the outer wall of the second connecting block 12 is fixedly connected with the second telescopic rod 9. The other end of the two telescopic rods 9 is fixedly connected with the fifth connecting block 34, the inner wa...

Embodiment 2

[0035] Such as Figure 1-10 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the top of the back-shaped fixed block 31 is fixedly connected with a plurality of anti-slip blocks 32, and the inner wall of the back-shaped fixed block 31 is fixedly connected with two fixed Rod 49, the outer wall of each fixed rod 49 is movably connected with a plurality of foot plates 27, the top of each foot plate 27 is fixedly connected with a plurality of identical anti-slip blocks 32, and the outer wall of the back-shaped fixed block 31 is fixedly connected with two handrails 10 , the other end of each handrail 10 is fixedly connected with the outer wall of the vehicle body 14, the outer wall of each handrail 10 is fixedly connected with a sponge cover 11, and the outer wall of the back-shaped fixed block 31 is fixedly connected with a baffle plate 28 near the box body 15 side.

[0036] In this embodiment, the anti-slip block 32 provided is made of r...

Embodiment 3

[0038] Such as Figure 1-10 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the inner wall of the box body 15 is fixedly connected with an engine 39 by being provided with bolts, and the outer wall of the engine 39 is fixedly connected with four sixth connecting blocks 37, each The inner wall of the sixth connecting block 37 is fixedly connected with two cooling pipes 38, and the inner wall of the box body 15 is fixedly connected with two second fixing blocks 50, and the side of each second fixing block 50 away from the inner wall of the box body 15 is toward the The slope of the engine 39 is inclined at 45 degrees, and the slope of each second fixed block 50 is fixedly connected with a cooling fan 40. The front and back sides of the casing 15 are provided with a plurality of cooling holes 29, and the bottom of the cooling hole 29 is to the casing 15. The outer wall is sloped at 30 degrees.

[0039] In the present embodiment, when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com