Method of inserting wire in rubber sleeving and rubber sleeving expander

A technology of diameter expander and sleeve, applied in the direction of electrical components, etc., can solve the problems of poor insertion operability, low rigidity, and difficult to shorten the state.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The method for inserting electric wires into a rubber sleeve and the rubber sleeve diameter expanding machine according to one embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

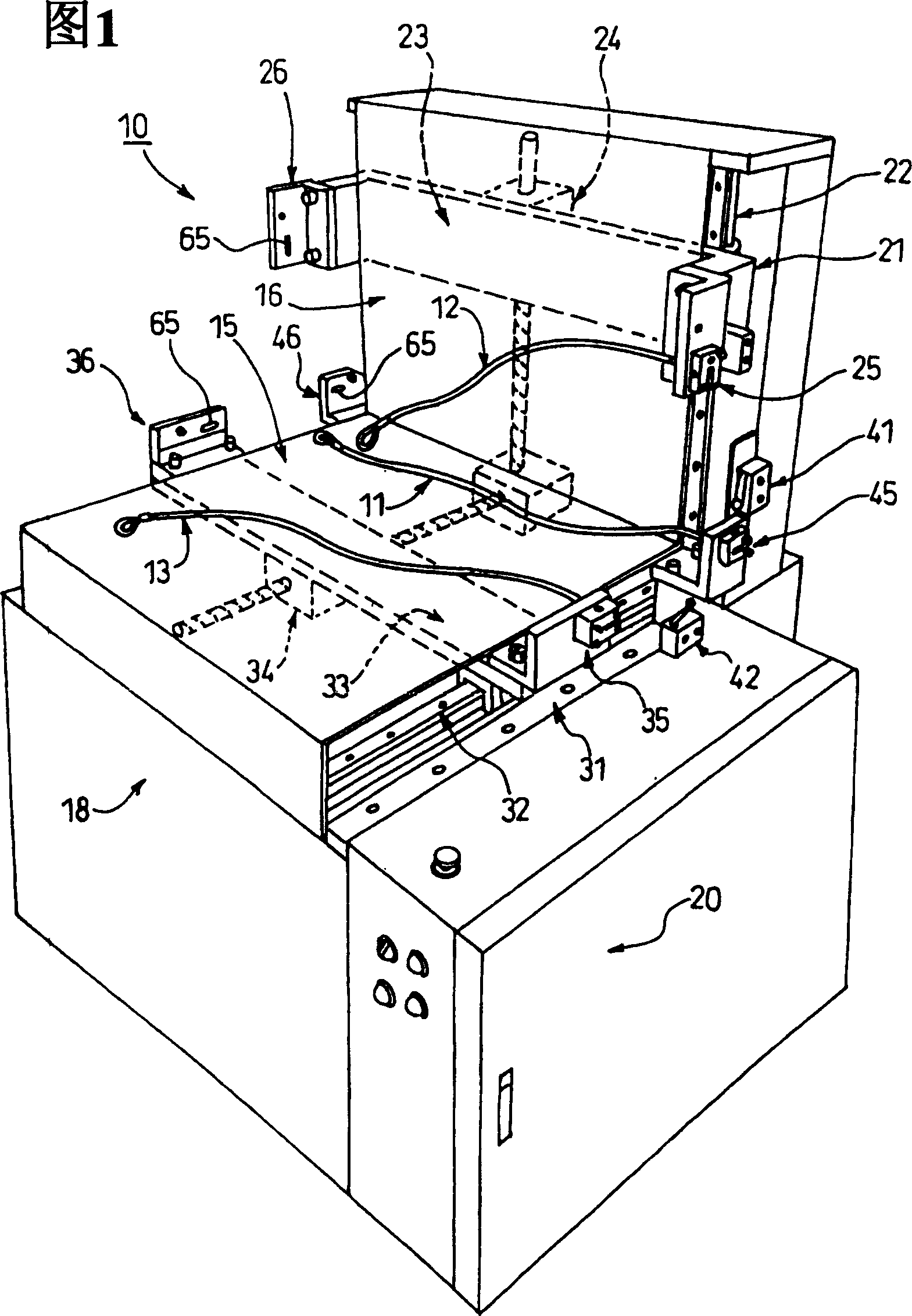

[0039] FIG. 1 shows an embodiment of a rubber tube expanding machine 10 of the present invention.

[0040] The rubber tube diameter expanding machine 10 of this embodiment, as shown in FIG. , 12, 13; drive means 21, 31 for changing the above-mentioned 2nd and 3rd diameter-expanding flexible long members 12, 13 supporting both ends to separate positions; console 18; and control means 20.

[0041]Above-mentioned driving device 21 comprises: a pair of linear guide rails 22,22 respectively configured on the left and right sides of the vertical plate 16 on the console 18; a movable member 23; and a roller screw 24 that converts the rotation of an unshown motor into linear motion in order to drive the movable member 23 in the vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com