Wood pattern with loose piece

A technology of wooden molds and live blocks, which is applied in casting and molding equipment and other directions, can solve the problems of difficult fixing, reduced work efficiency, easy to fall off, etc., and achieves the effects of convenient mold removal, accurate size and improved work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

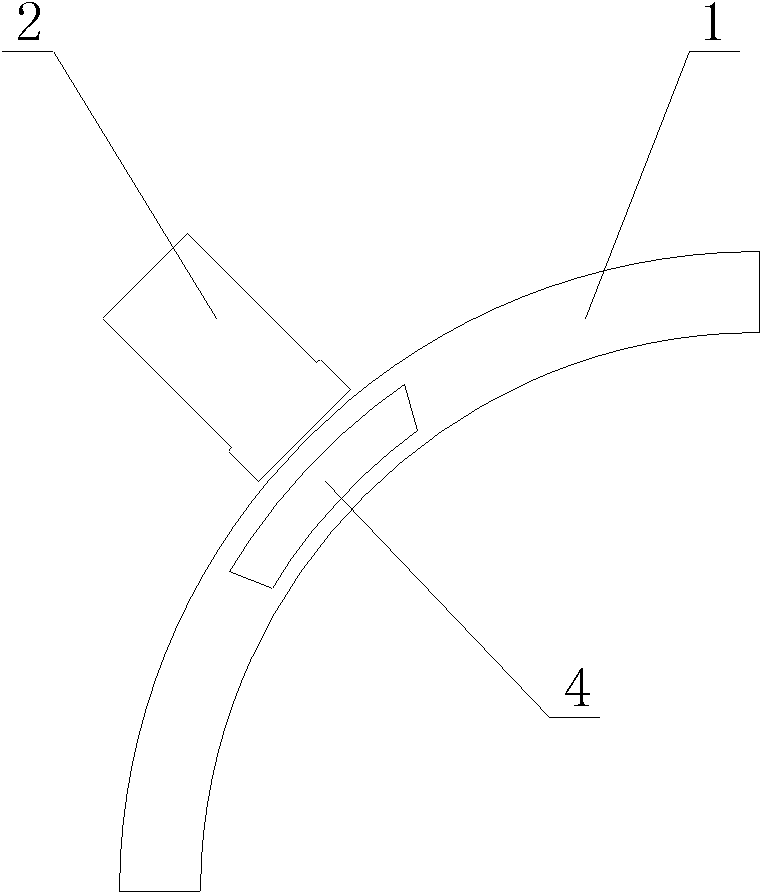

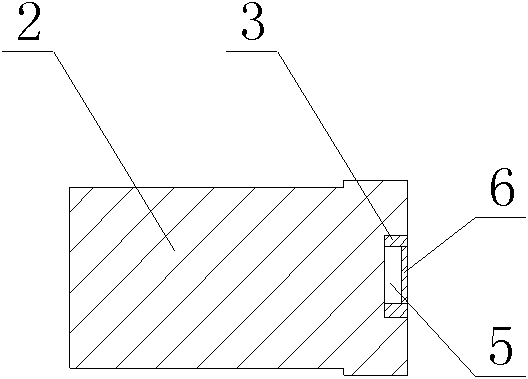

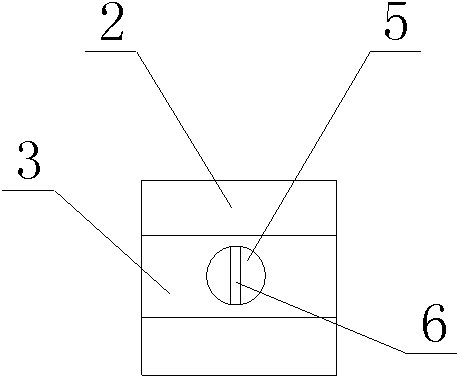

[0011] Such as figure 1 , figure 2 and image 3 Shown, a kind of wooden formwork with movable block, comprises wooden formwork main body 1, the movable block 2 that is located on wooden formwork main body 1, the rear end center of described movable block 2 is provided with iron plate 3, and described wooden formwork The main body 1 is provided with a magnet 4 corresponding to the iron plate 3 . When the loose block 2 was placed on the wooden formwork main body 1, due to the effect of the iron plate 3 and the magnet 4, the loose block 2 was not easy to drop. The center of the iron plate 3 is provided with a lifting hole 5, and the lifting hole 5 is provided with a lifting handle 6. It is convenient to use the hook to hook the lifting handle 6 to pull out the movable block 2 smoothly, the structure is simple, the mold is convenient to pull out, the size of the casting is guaranteed to be accurate, and the work efficiency is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com