Separator for battery, battery using same and method for producing battery

一种隔膜、电池的技术,应用在隔膜的改良领域,能够解决漏电的制品不良、隔膜表面滑动性低、隔膜损伤等问题,达到降低摩擦的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

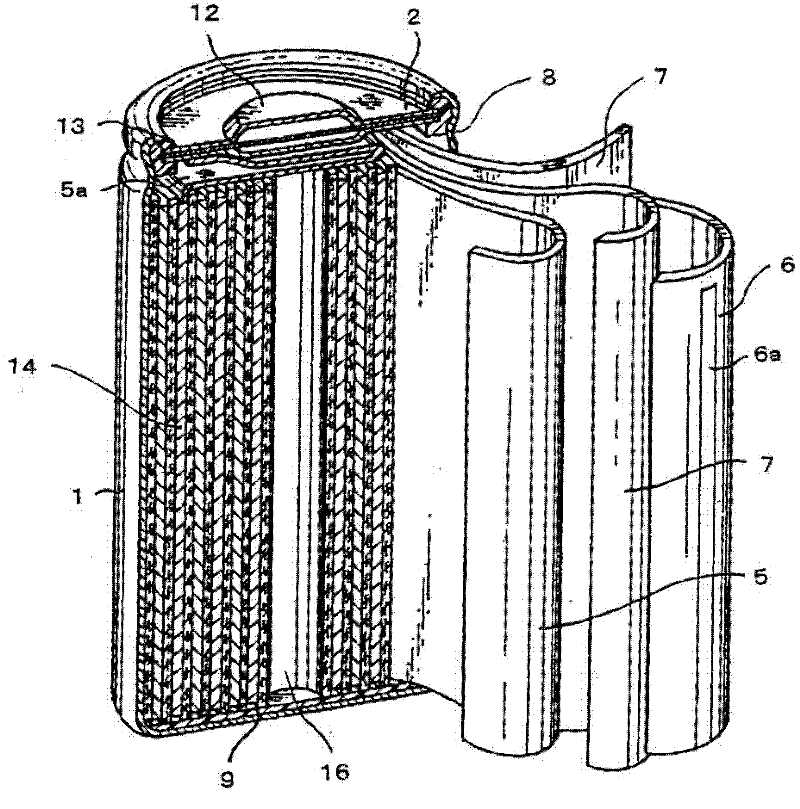

[0117] make figure 1 Shown is a cylindrical lithium ion secondary battery (battery A) equipped with a wound electrode group. The battery is a 18650 type with a diameter of 18.1mm and a height of 65.0mm, and a nominal capacity of 2600mAh. As the battery case 1 , a metal case (diameter: 17.8 mm, overall height: 64.8 mm) obtained by press-forming a nickel-plated steel sheet (wall thickness: 0.20 mm) was used.

[0118] The non-aqueous electrolyte was prepared as follows: LiPF was dissolved at a concentration of 1.0M in a mixed solvent of ethylene carbonate and ethyl methyl carbonate (volume ratio 2:1) 6 , and prepared by adding cyclohexylbenzene at a concentration of 0.5% by weight.

[0119] In addition, the wound electrode group was produced as follows (1) to (4).

[0120] (1) Fabrication of diaphragm

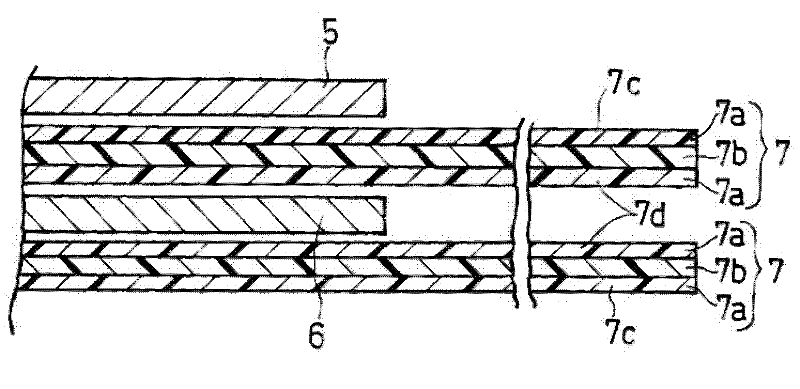

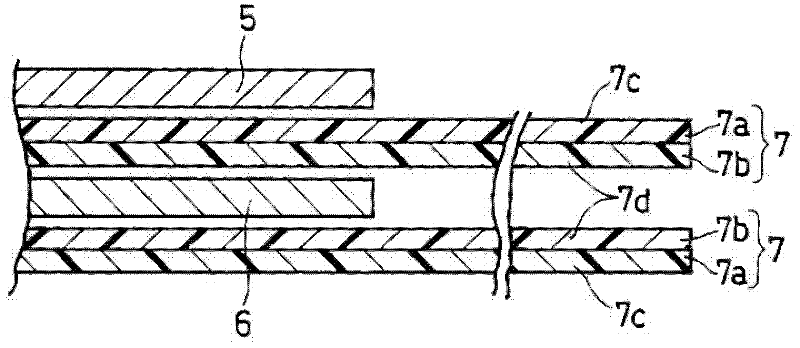

[0121] form figure 2 A separator 7 having a three-layer structure (20 μm in thickness) having a porous polyethylene layer 7 a as an inner layer and a pair of porous polyprop...

Embodiment 2 and comparative example 1

[0139] A separator having a three-layer structure was produced in the same manner as in Example 1, except that the porosity and pore diameter range on the surface of the porous polypropylene film were changed to the values shown in Table 1. Except having used the obtained separator, it carried out similarly to Example 1, and produced 300 electrode groups for each example. Batteries B to L were produced using the remaining electrode group except for the electrode group in which the separator could not be fed out well by the roller during winding, and the winding misalignment occurred due to poor winding of the separator. In Table 1, the number of electrode groups in which winding defects occurred among the 300 electrode groups is represented by "defective winding".

[0140] In addition, the opening ratio and opening diameter range were adjusted by adjusting the stretching conditions of the porous polypropylene film. The thicknesses of the separators 7 were all set to 20 μm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| apparent porosity | aaaaa | aaaaa |

| apparent porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com