Sand protection matching pipe string for high-throughput sand filter pipe

A high-flux, sand filter technology, applied in casing, drill pipe, wellbore/well components, etc., can solve problems such as inability to use horizontal wells for sand control, oilfield economic losses, and difficulty in replacing sand filters, and reduce seepage. The effect of preventing leakage, improving the speed and volume of liquid collection, and reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

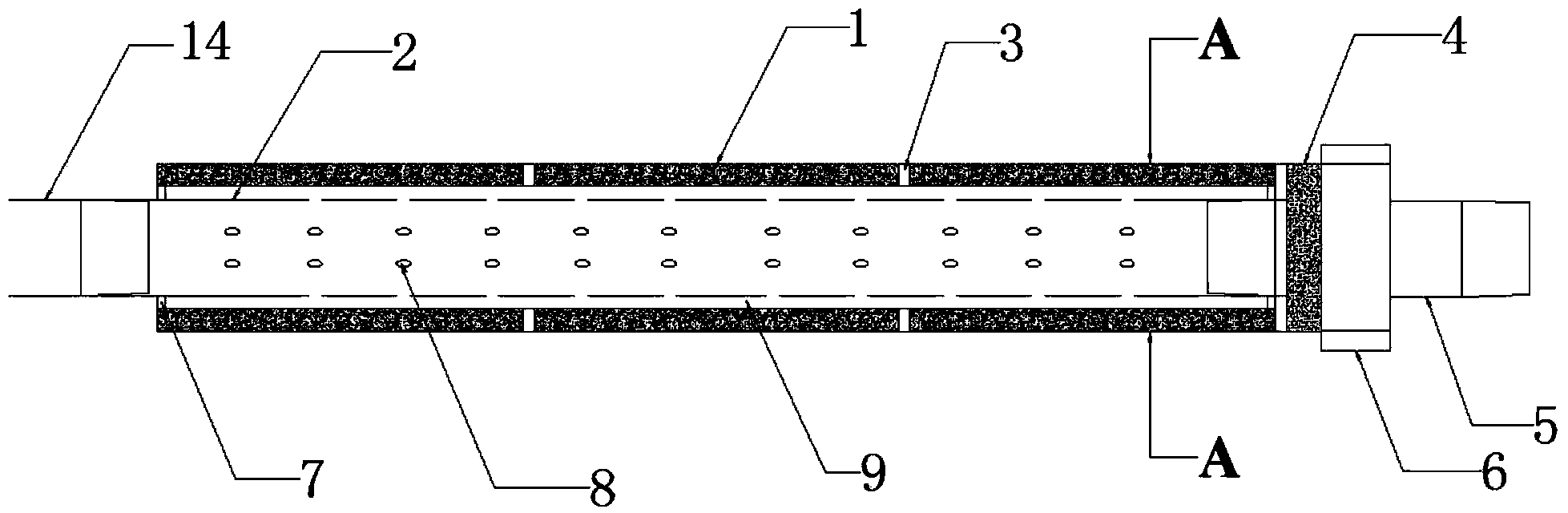

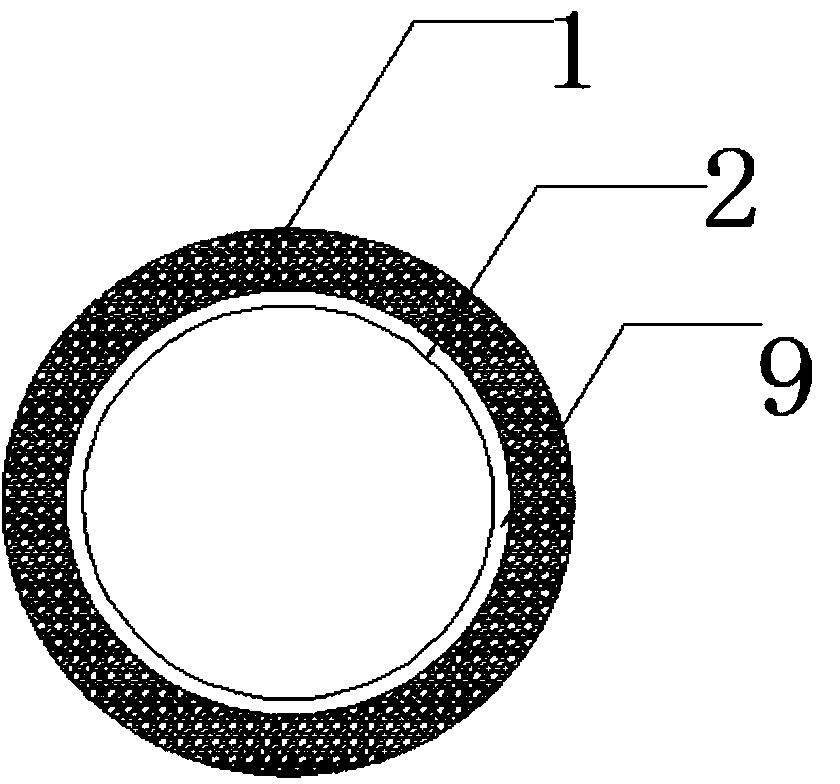

[0044] A high-throughput sand filter pipe sand control matching string suitable for high-temperature thermal recovery horizontal wells, including a packer 19, a conversion collar 14, a high-flux sand filter pipe and a plug 13, and the conversion collar 14 is connected to the packer The device 19 is set at the rear end of the high-throughput sand filter tube, and the plug 13 is set at the front end of the high-flux sand filter tube;

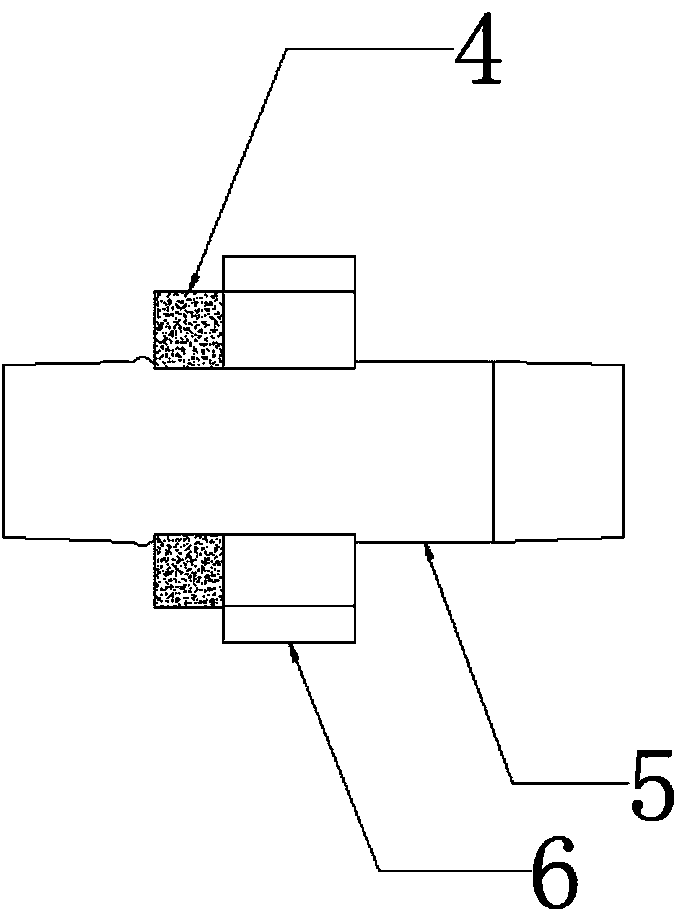

[0045] The high-throughput sand filter pipe is connected end-to-end sequentially by the high-flux sand filter unit through double male reverse buckle couplings 5, and the middle outer surface of the double male reverse buckle couplings 5 is provided with a high temperature resistant mashable centralizer 6, The breakable bracket 4 is arranged between the high-temperature-resistant breakable centralizer 6 on the outer surface of the double-male buckle collar 5 and the high-throughput sand filter unit;

[0046] The above-mentioned high-throughput s...

Embodiment 2

[0055] A high-flux sand filter tube sand control matching string suitable for high-temperature thermal recovery vertical wells, including a packer 19, a conversion collar 14, a high-flux sand filter tube, a tailpipe 20, a plug 13, and a conversion collar 14 The connecting packer 19 is set at the rear end of the high flux sand filter pipe, and the plug 13 communicates with the front end of the high flux sand filter pipe through the tailpipe 20;

[0056] The high-throughput sand filter pipe is connected end-to-end sequentially by the high-flux sand filter unit through double male reverse buckle couplings 5, and the middle outer surface of the double male reverse buckle couplings 5 is provided with a high temperature resistant mashable centralizer 6, The breakable bracket 4 is arranged between the high-temperature-resistant breakable centralizer 6 on the outer surface of the double-male buckle collar 5 and the high-throughput sand filter unit;

[0057] The above-mentioned high-...

Embodiment 3

[0066] A high-throughput sand filter tube sand control matching string suitable for normal temperature horizontal wells, including a packer 19, a conversion collar 14, a high-flux sand filter tube and a time-delay self-locking valve 13, the conversion collar 14 is connected to the seal The spacer 19 is set at the rear end of the high-flux sand filter tube, and the time-delay self-locking valve 13 is set at the front end of the high-flux sand filter tube;

[0067] The high-throughput sand filter pipe is connected end-to-end sequentially by the high-flux sand filter unit through double male reverse buckle couplings 5, and the middle outer surface of the double male reverse buckle couplings 5 is provided with a high temperature resistant mashable centralizer 6, The breakable bracket 4 is arranged between the high-temperature-resistant breakable centralizer 6 on the outer surface of the double-male buckle collar 5 and the high-throughput sand filter unit;

[0068]The above-menti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com