Connector, adapter and quick-plug optic fiber connection component

An optical fiber connection and connector technology, applied in the field of optical distribution network, can solve the problem of small pull-out force, and achieve the effect of small pull-out force, large locking force and small insertion force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

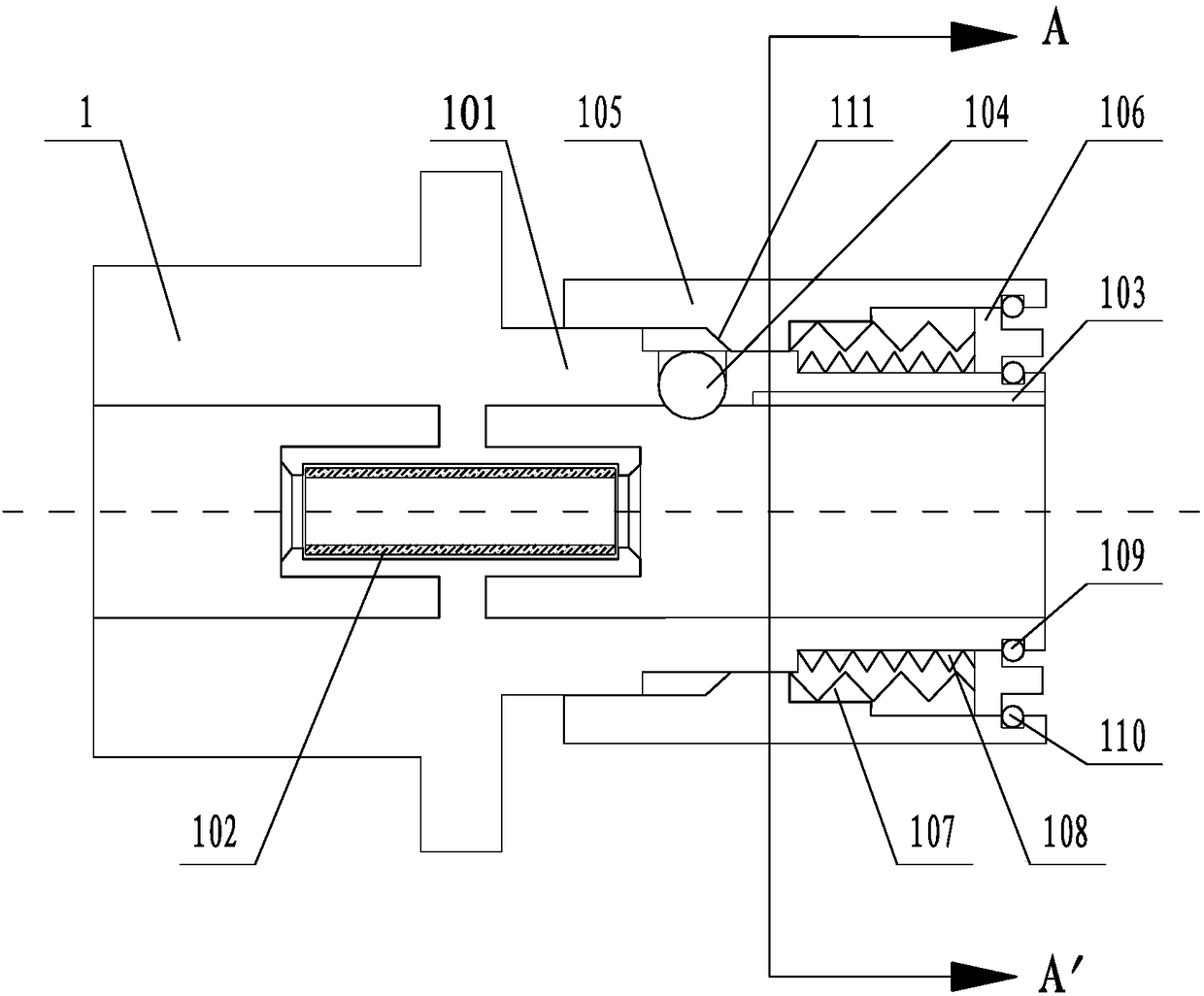

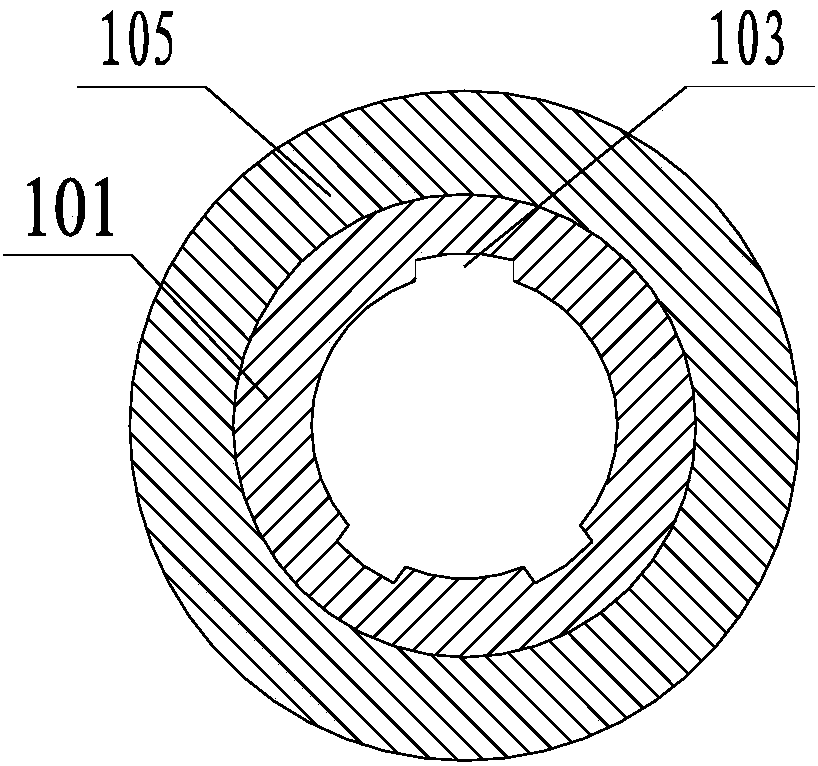

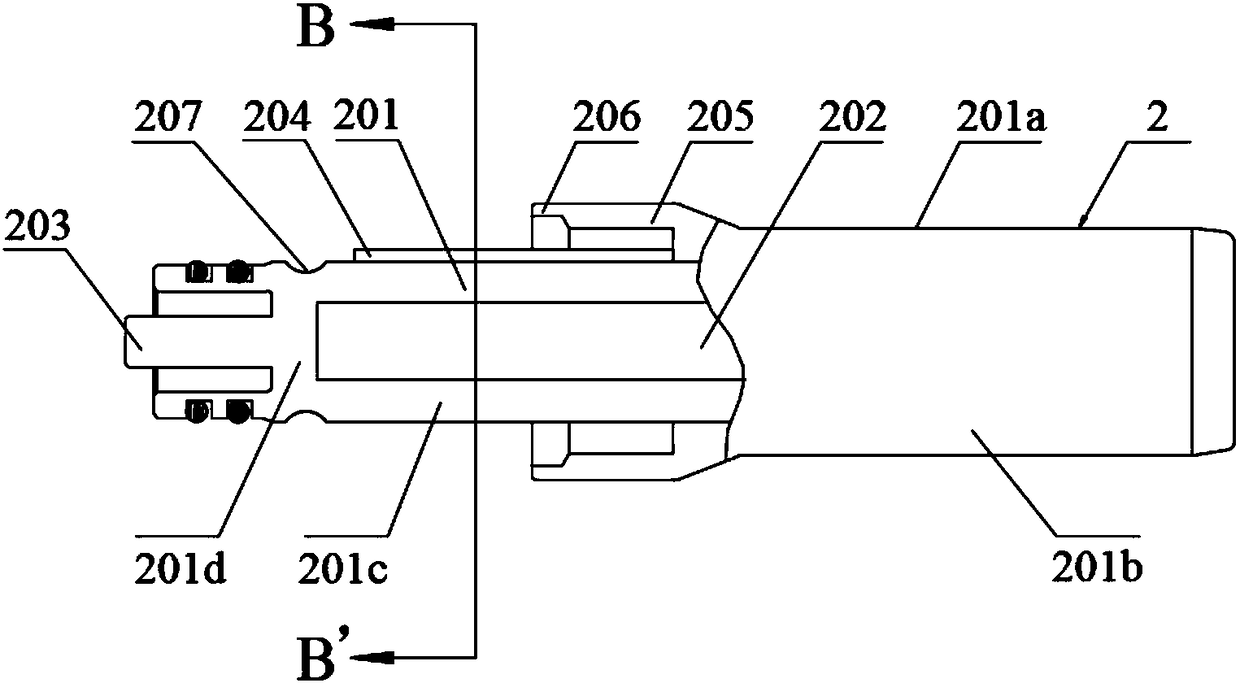

[0105] Please also refer to Figure 1 to Figure 19 , the embodiment of the present invention provides a connector 2, which is used for optical fiber connection, and the connector 2 includes a plug body 201, and the plug body 201 is used for carrying an optical cable 215 and for hand-held operation. The outside of the plug body 201 is provided with a plug housing 205, and the front end of the plug housing 205 has a pushing device 206; the outer surface of the plug body 201 is provided with a groove for engaging with an adapter matching the connector. The groove may be an annular groove 207 . Compared with the connection method using threads in the prior art, the use of grooves as the connection structure can withstand greater pull-off force, and does not need to be rotated, can be inserted directly, and is easy to operate. And since there is no need to rotate, the space required for hand operation is small, which can increase the density of the connector on the panel.

Embodiment 2

[0107] Please also refer to Figure 1 to Figure 19 , as an optional embodiment, the difference between this embodiment and Embodiment 1 is that: the pushing device 206 is used to push the inner sleeve 106 of the adapter 1 adapted to the connector 2 . To make adapter 1 change state to connect with connector. Of course, the ejecting device 206 can also eject other similar structures of the adapter 1, as long as it can change the state of the adapter 1 and achieve the effect of connection.

Embodiment 3

[0109] Please also refer to Figure 1 to Figure 19 , as an optional embodiment, the difference between this embodiment and Embodiment 1 is that the ejecting device 206 is an ejecting block formed by extending from the outer surface of the plug body 201 . If the ejector device 206 adopts this structure, then the inner sleeve 106 matched with the ejector device 206 can be provided with a protrusion protruding from the outer sleeve 205 (not shown), so that the ejector device 206 can push the inner sleeve 106 And move axially relative to the outer sleeve 205 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com