Cloth cutting machine

A cutting machine and fabric technology, which is applied in the cutting of textile materials, textiles and paper making, etc., can solve the problems of inconvenient use and hiding of pulleys, no electro-hydraulic rods, no rotating handles, etc., so as to avoid cutting. The effect of accuracy, improving cutting quality, increasing stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

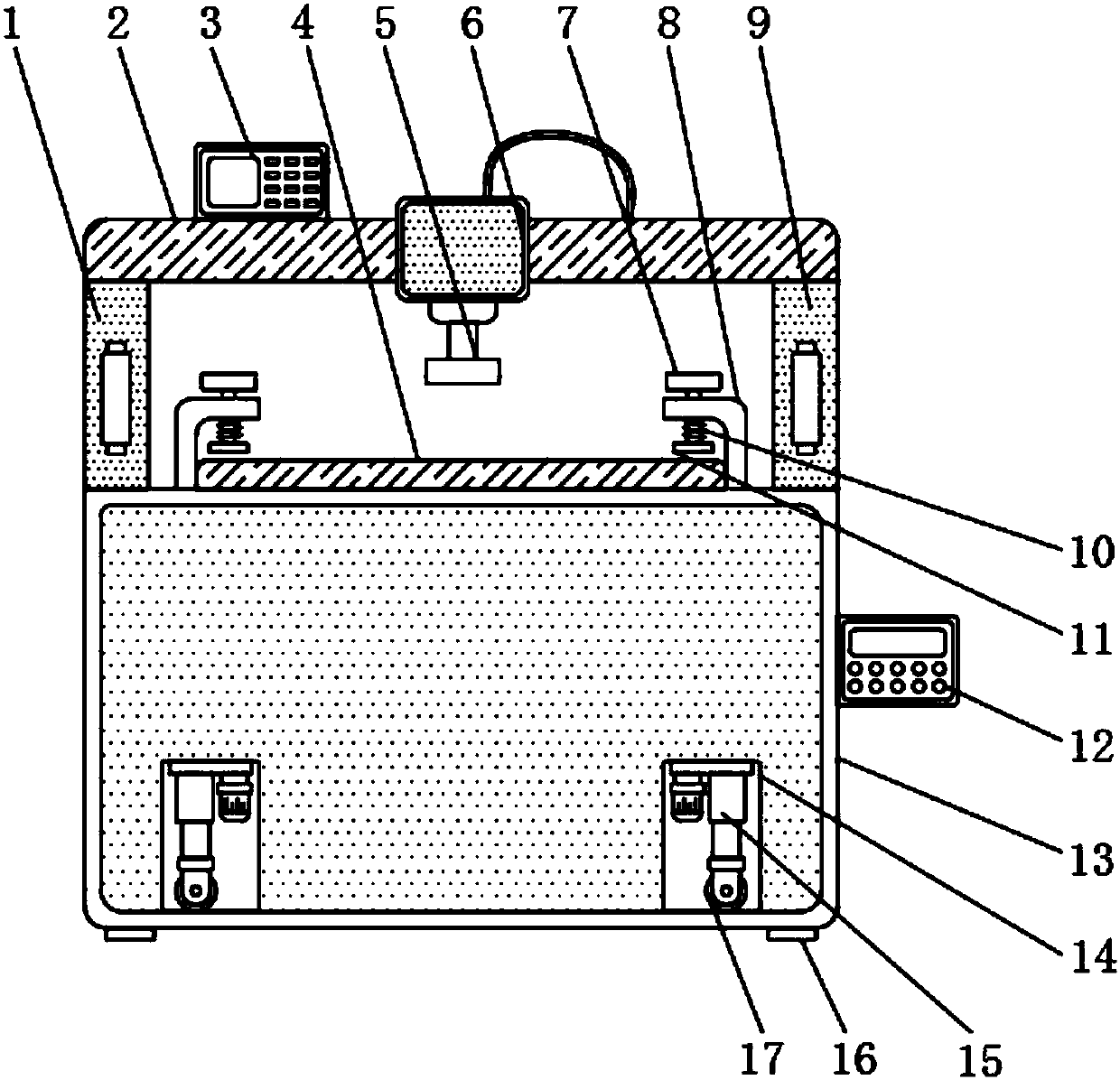

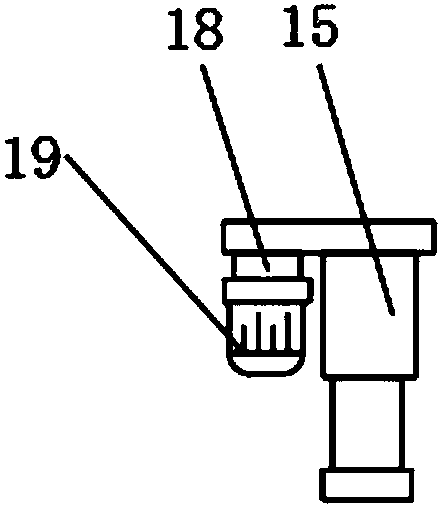

[0021] Example: such as Figure 1-2 As shown, the present invention provides a technical solution, a cloth cutting machine, including a cutting machine body 13 and a fixed frame 8, the top of the cutting machine body 13 is provided with a cutting table 4, and the cutting machine body 13 One side is provided with a PLC controller 12, the top of the cutting machine body 13 is provided with a right bracket 9 near the position on one side of the cutting table 4, and the top of the cutting machine body 13 is provided near the other side of the cutting table 4 Left support 1 is arranged, the inside of cutting machine body 13 is provided with chute 14, and the bottom end of cutting machine body 13 is provided with supporting foot 16, and fixed frame 8 is installed on one end of cutting table 4, and the end of fixed frame 8 The interior is embedded with a threaded rod 10, the top of the threaded rod 10 is provided with a rotating handle 7, and the bottom of the threaded rod 10 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com