Function integrated numerically controlled automatic leather cutting method

An integrated leather technology, applied in leather punching/punching/cutting, digital control, small raw leather/big raw leather/leather/fur treatment, etc., to achieve flexible changes, reduce labor force, and improve cutting quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

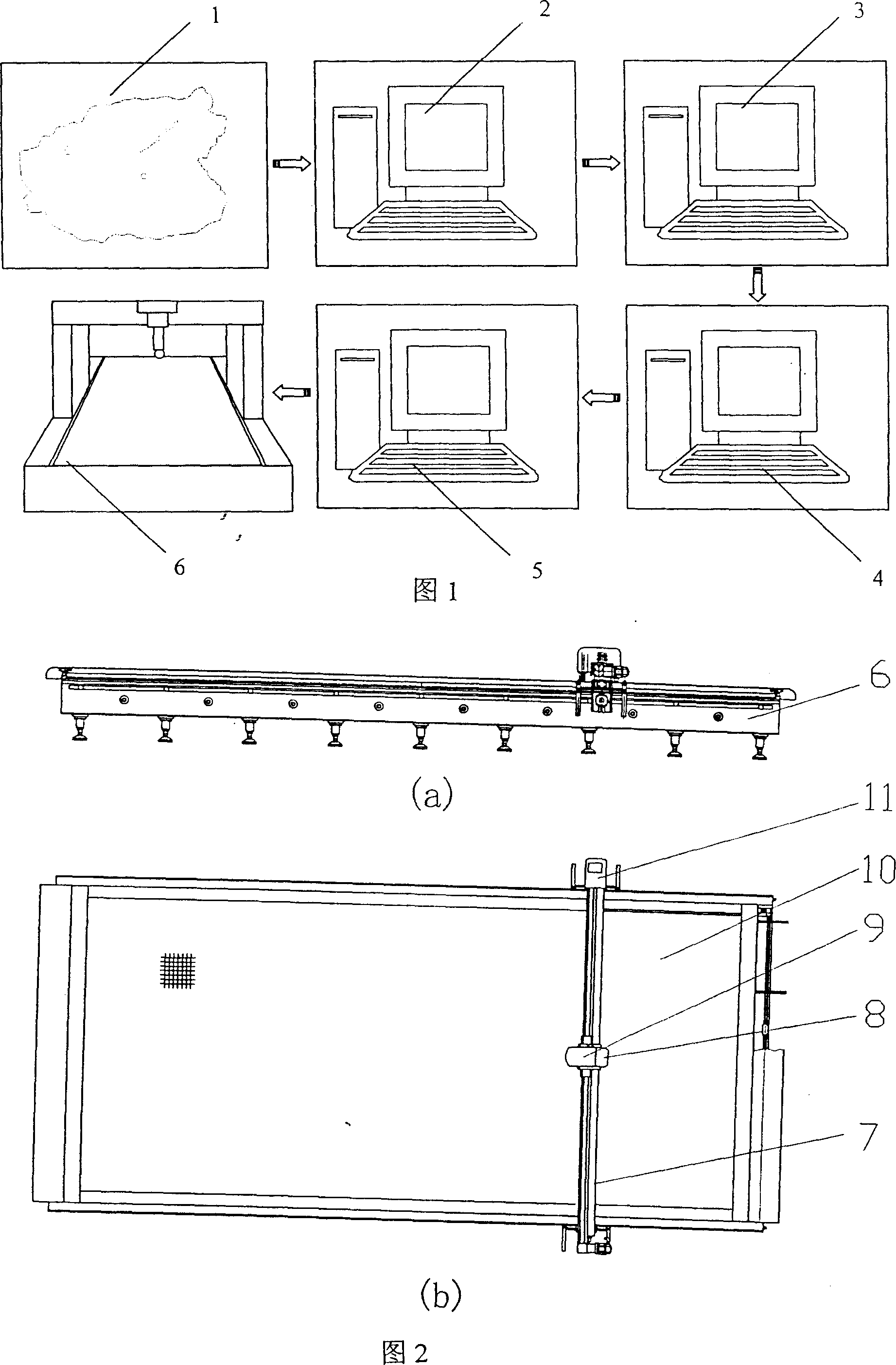

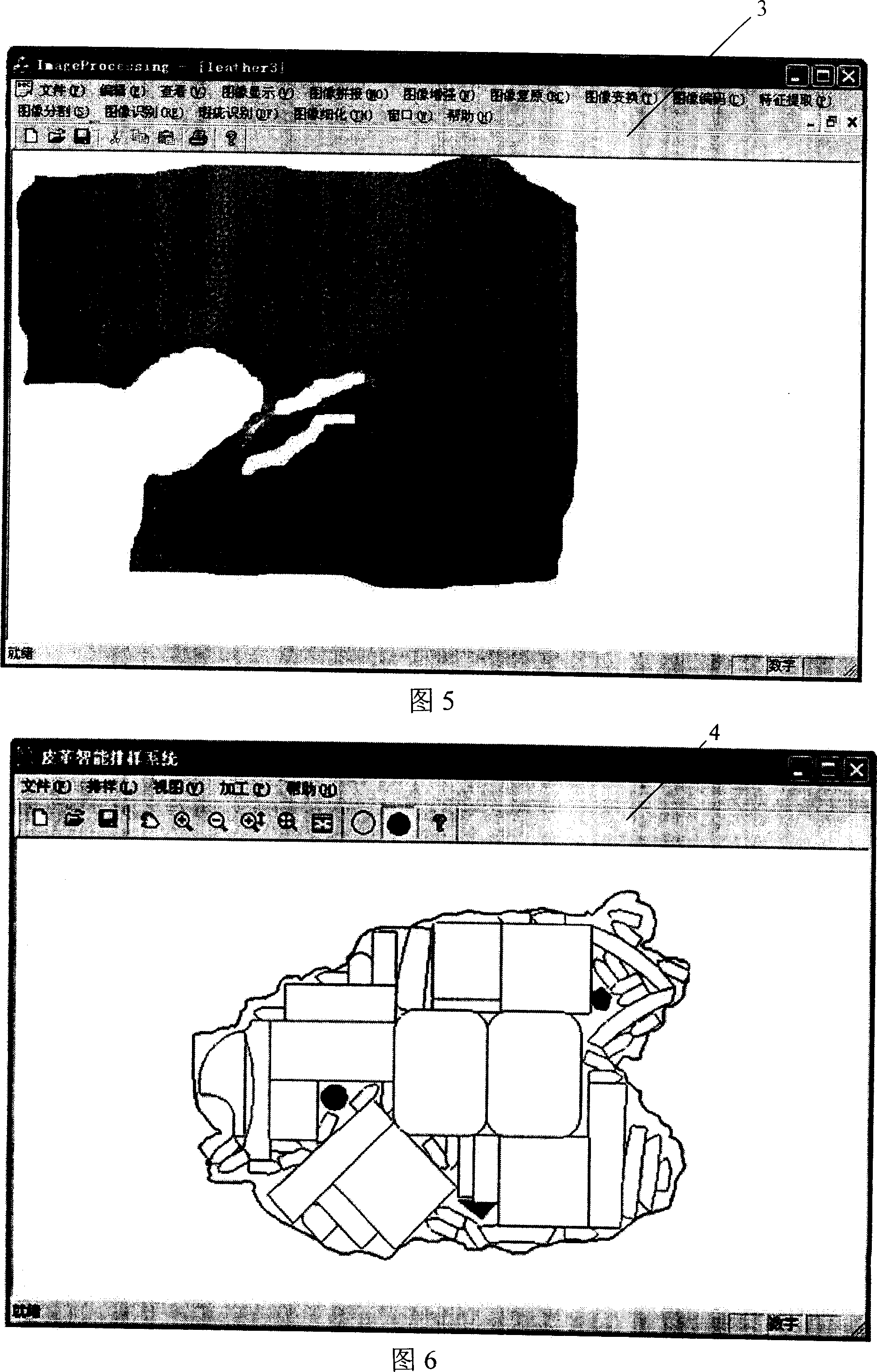

[0019] The present invention will be further described below in conjunction with drawings and embodiments.

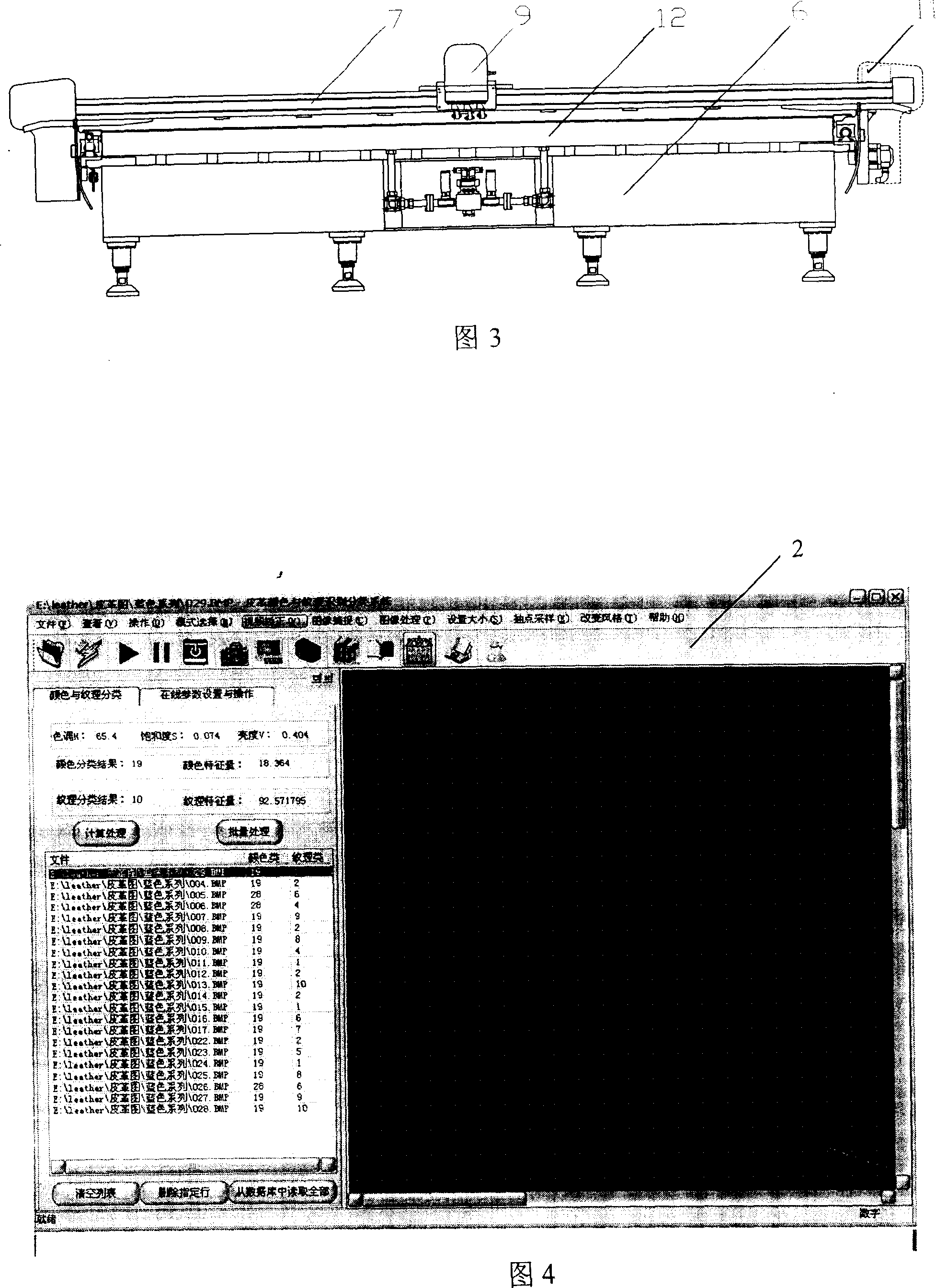

[0020] As shown in Figures 1 and 2, the leather material 1 is placed on the porous work surface 10 of the cutting bed 6, and the vacuum adsorption system 12 is opened as shown in Figure 3. Through the suction port on the work surface, the vacuum adsorption system 12 will The leather material 1 is adsorbed on the porous work surface 10 as shown in FIG. 2 , and other leather material 1 positioning methods can also be used to position the leather material 1 on the work surface. As shown in Figure 2, open the crossbeam 7 drive motor, drive the crossbeam 7 to move with a certain step along the longitudinal direction of the cutting bed 6, and when the crossbeam 7 moves a step every time, start the multifunctional cutting knife rest 9 on the crossbeam 7 The drive motor drives the multifunctional cutting tool rest 9 to move along the crossbeam 7. At this time, when the crossbea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com