Organic mineral fertilizer and preparation method thereof

A technology of organic minerals and fertilizers, applied in the field of agriculture and forestry, can solve the problems of easily damaged soil nutrient content, low nutrient content of farmyard manure, and low degree of harmlessness, and achieve good soil conditions, high organic matter content, and enhanced disease resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

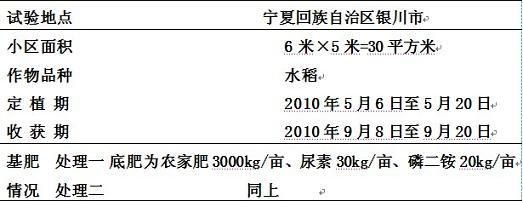

Embodiment 1

[0052] Prepare 1000kg organic mineral fertilizer:

[0053] Step 1: Choose zeolite powder less than or equal to 60 mesh, humic acid (salt), calcium magnesium phosphate fertilizer, and plant ash, and air-dry or dry them for later use;

[0054] Step 2: Weigh the spare zeolite powder less than or equal to 60 mesh, humic acid (salt), calcium magnesium phosphate fertilizer, and plant ash in step 1 according to the weight of the components, 400kg of zeolite powder less than or equal to 60 mesh, humic acid (salt) ) 250kg, calcium magnesium phosphate fertilizer 200kg and plant ash 150kg, put them in a mixer and mix them, granulate with a granulator, bake in a baking machine at 300°C for 35 minutes, and sieve with a sieving machine to make an organic mineral fertilizer .

Embodiment 2

[0056] Prepare 1000kg organic mineral fertilizer:

[0057] Step 1: Choose zeolite powder less than or equal to 60 mesh, humic acid (salt), calcium magnesium phosphate fertilizer, and plant ash, and air-dry or dry them for later use;

[0058] Step 2: Weigh the spare zeolite powder less than or equal to 60 mesh, humic acid (salt), calcium magnesium phosphate fertilizer, and plant ash in step 1 according to the weight of the components, 600kg of zeolite powder less than or equal to 60 mesh, humic acid (salt) ) 200kg, calcium magnesium phosphate fertilizer 100kg and plant ash 100kg, put them in a mixer and mix them, granulate through a granulator, bake in a baking machine at 400°C for 20 minutes, and sieve with a sieving machine to make an organic mineral fertilizer .

Embodiment 3

[0060] Prepare 1000kg organic mineral fertilizer:

[0061] Step 1: Choose zeolite powder less than or equal to 60 mesh, humic acid (salt), calcium magnesium phosphate fertilizer, and plant ash, and air-dry or dry them for later use;

[0062] Step 2: Weigh the spare zeolite powder less than or equal to 60 mesh, humic acid (salt), calcium magnesium phosphate fertilizer, and plant ash in step 1 according to the weight of the components, 150kg of zeolite powder less than or equal to 60 mesh, humic acid (salt) ) 300kg, calcium magnesium phosphate fertilizer 300kg and plant ash 250kg, put them in a mixer and mix them, granulate with a granulator, bake in a baking machine at 200°C for 50 minutes, and sieve with a sieving machine to make an organic mineral fertilizer .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com