Multifunctional damper

A shock absorber and multi-functional technology, applied in the direction of low internal friction spring, coil spring, etc., can solve the problem of poor shock absorption effect of shock absorber and achieve good shock absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

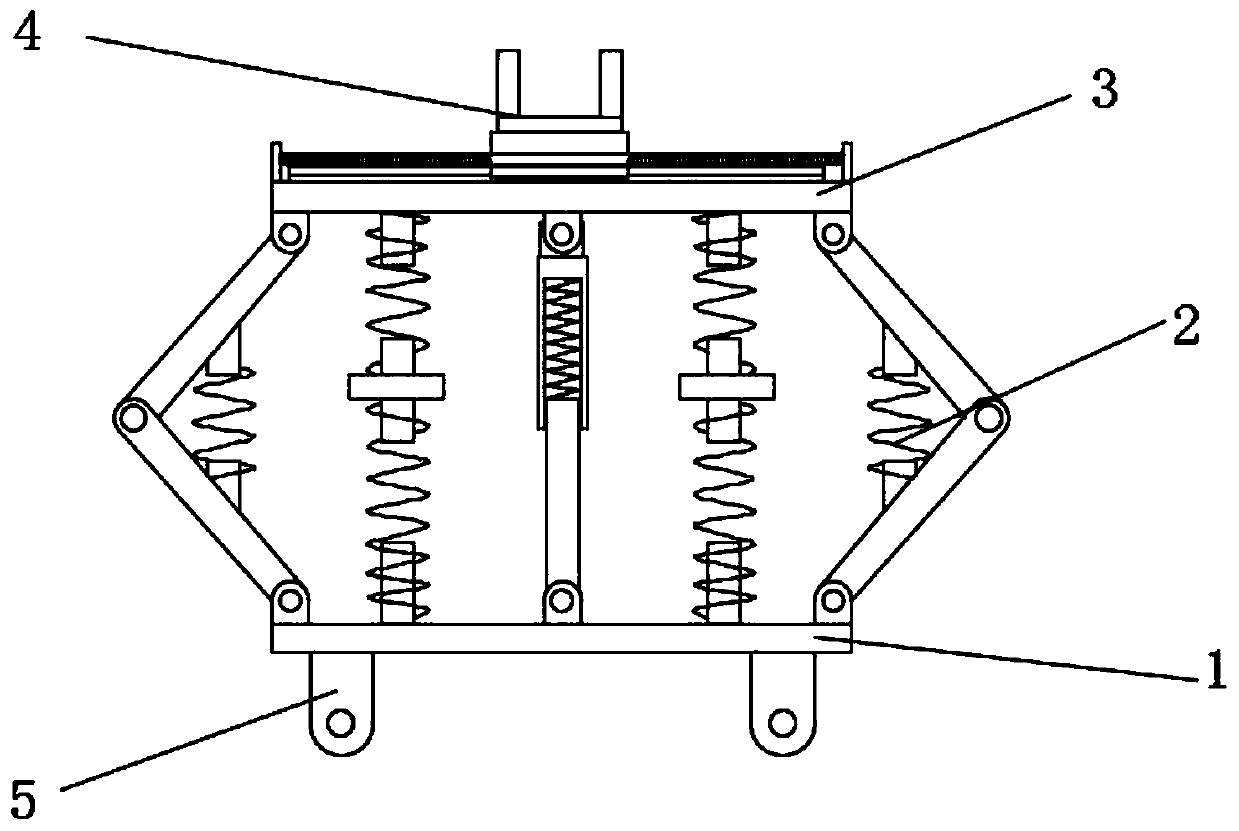

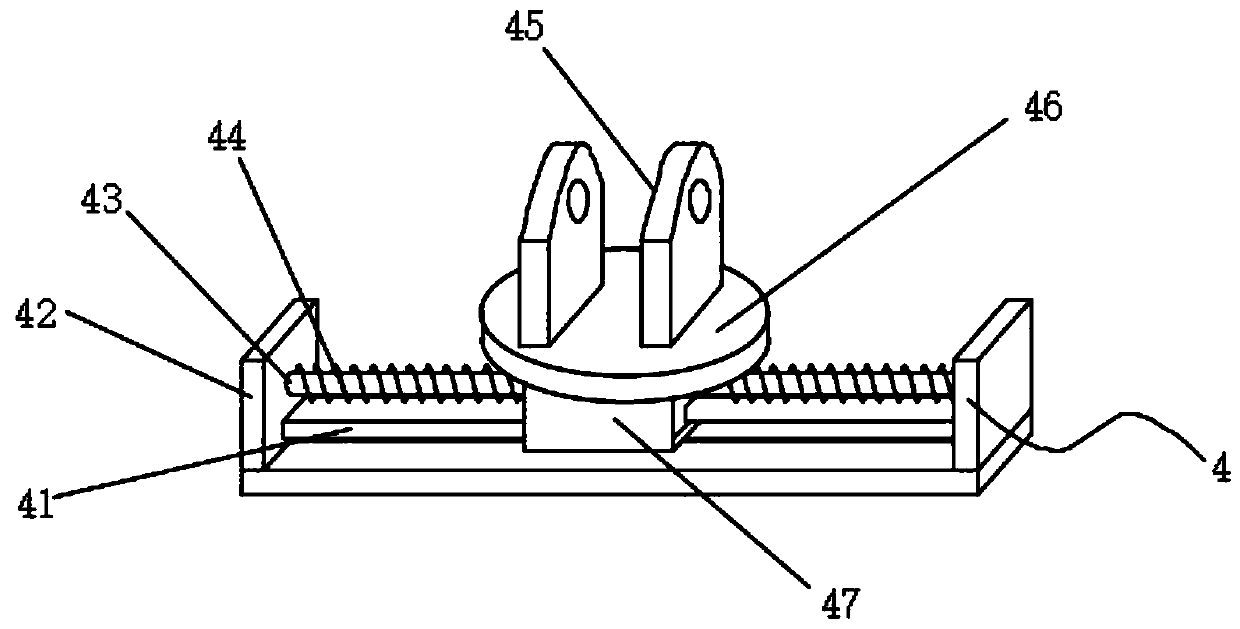

[0029] Such as Figure 1-3 As shown, a multifunctional shock absorber includes: a fixed plate 1, a shock absorbing structure 2, a support plate 3, a sliding structure 4 and a fixed support 5, and the support plate 3 is arranged directly above the fixed plate 1, The shock absorbing structure 2 is arranged between the fixed plate 1 and the support plate 3, the sliding structure 4 is installed on the top side of the support plate 3, and the bottom of the fixed plate 1 is welded and fixed with two fixed supports 5;

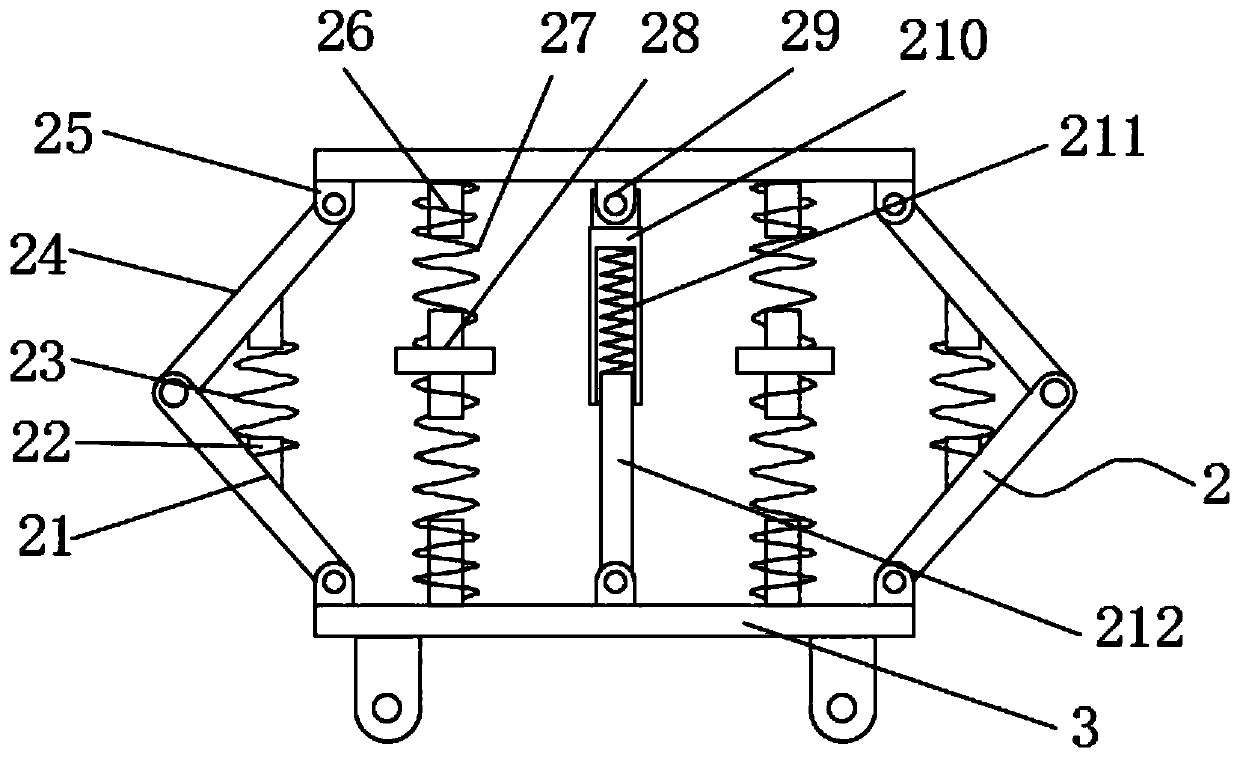

[0030] The shock absorbing structure 2 includes a first side connecting rod 21, a limit rod 22, a limit spring 23, a second side connecting rod 24, a first connecting support 25, a positioning rod 26, a shock absorbing spring 27, a cross The positioning frame 28, the second connecting support 29, the shock absorbing sleeve 210, the return spring 211 and the shock absorbing insert rod 212, the top side of one end of the fixed plate 1 and the bottom side of one end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com