Thin-wall three-way pipe clamping device

A technology of clamping device and tee pipe, which is applied in the direction of auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of time-consuming and laborious, low processing accuracy, and low operation efficiency, and achieve accurate positioning and lighten Self-respect, effect of improving versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

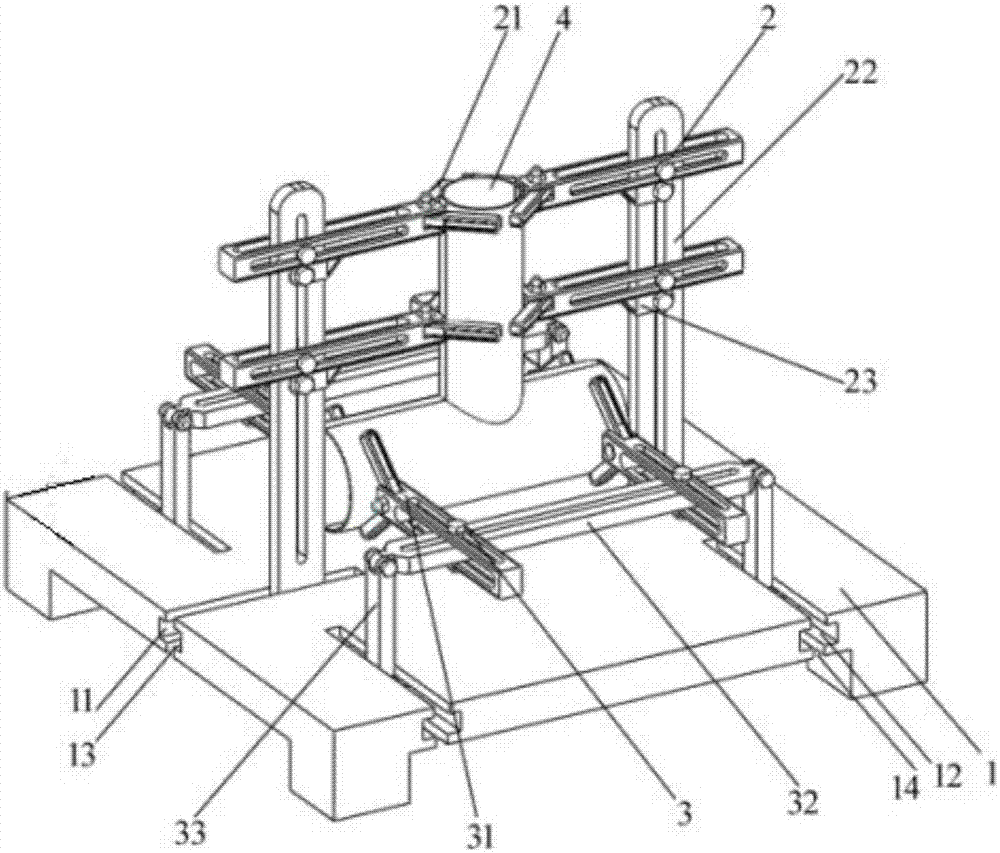

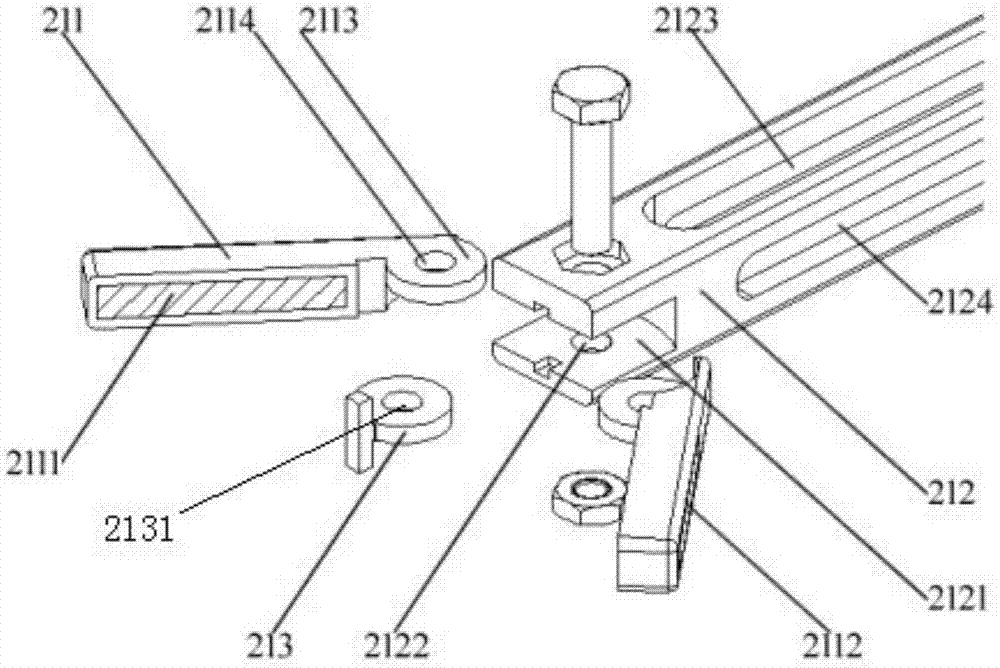

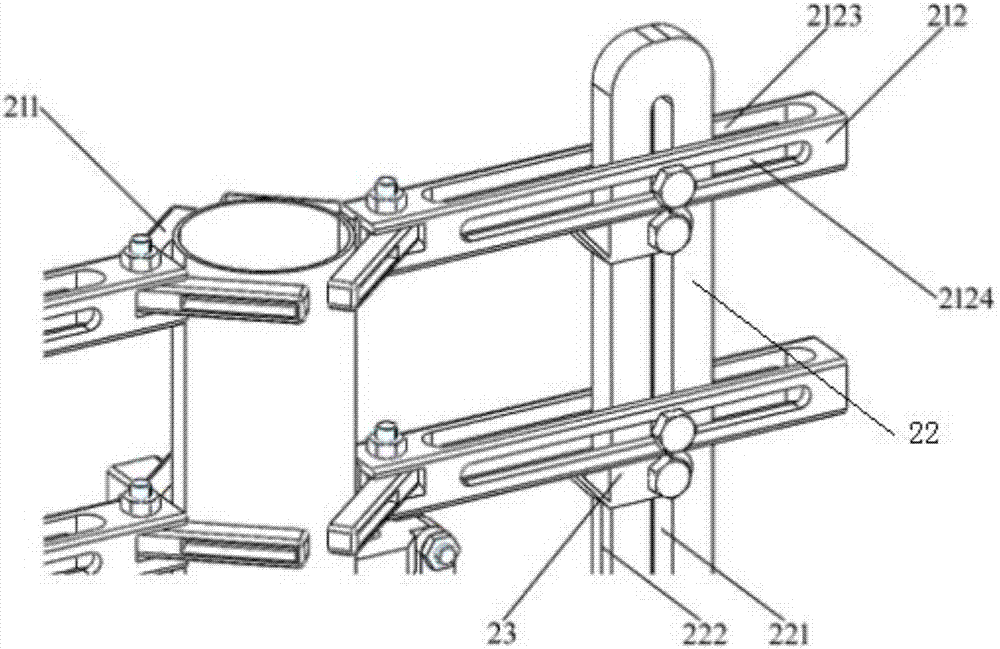

[0028] A kind of thin-walled tee pipe clamping device of the present embodiment, such as Figure 1-6 As shown, it includes a bottom plate 1, and the thin-walled three-way pipe vertical section clamping module 2 and the thin-walled three-way pipe horizontal section clamping module 3 are installed on the described bottom plate 1; the thin-walled three-way pipe vertical section The section clamping module 2 includes a vertical slide bar 22 that is movably installed on the base plate 1, and the vertical section V-shaped clamping mechanism 21 is movably installed on the described vertical slide bar 22, and the described vertical slide bar 22 and A trapezoidal support frame 23 for positioning is installed between the V-shaped clamping mechanisms 21 of the vertical section; the clamping module 3 of the horizontal section of the thin-walled tee pipe inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com