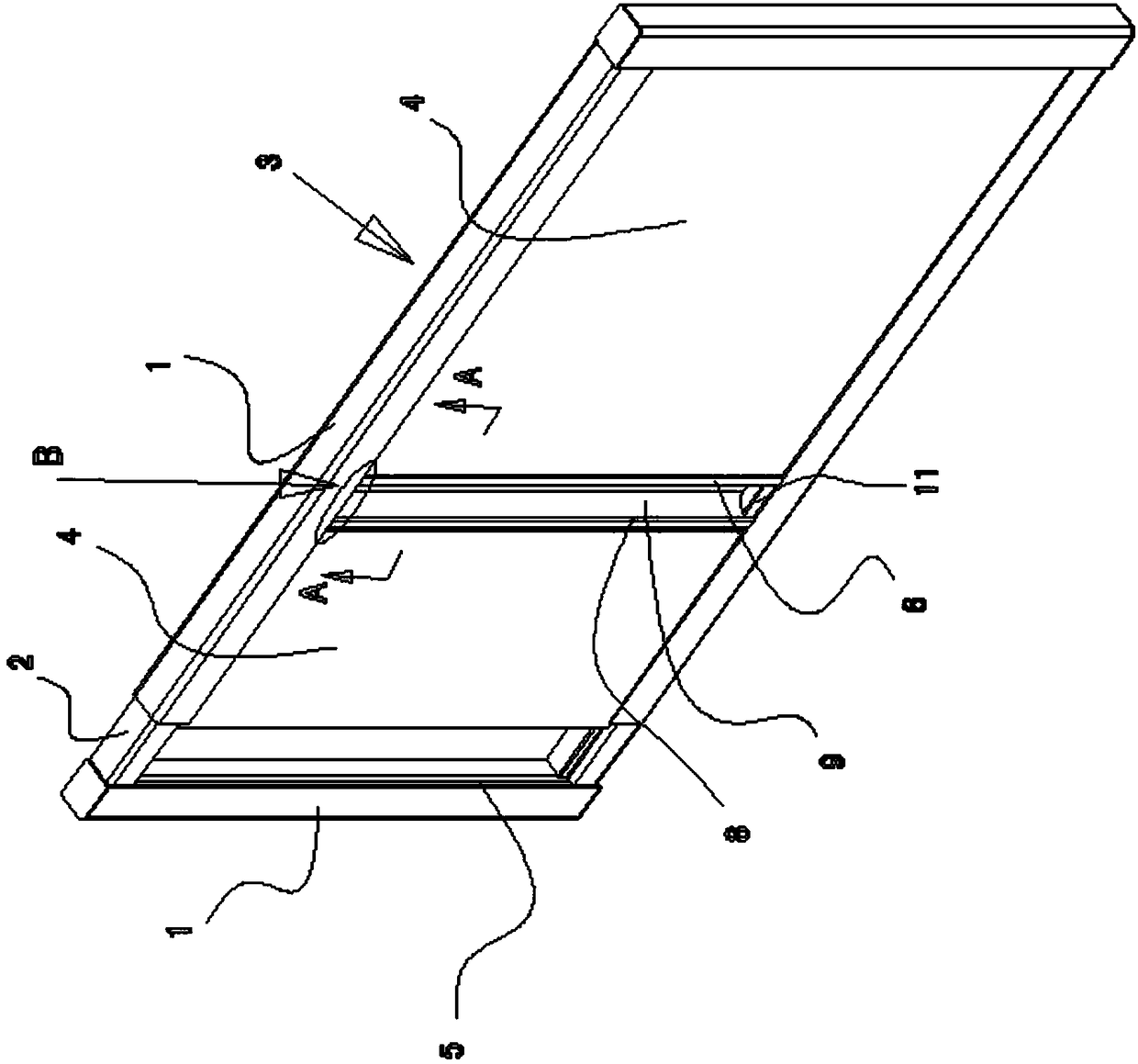

Manufacturing method of green and environment-friendly solid wood multilayer decorative board

A green environmental protection and production method technology, applied in the field of flame retardant materials, can solve the problems of increasing auxiliary treatment, increasing application, and returning frost, and achieves the effects of improving fire resistance and flame retardant performance, improving packing tightness, and low thermal seepage coefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

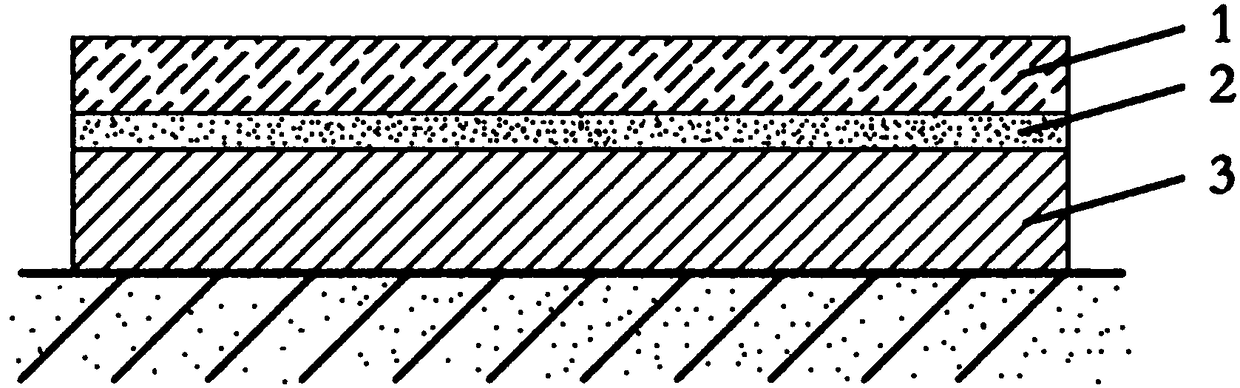

[0044] 1) Preparation of modified expandable graphite: add KMnO4 to flake graphite according to the ratio of mass ratio flake graphite: KMnO4 = 1:0.3, stir evenly, add 70% HClO3 solution, and maintain the ratio of solid to liquid at 1:4 Keep stirring at 35°C for 90 minutes, wash with water, filter with suction, and dry to obtain modified expandable graphite with an expansion volume of 550ml / g2) Preparation of modified expandable polystyrene: mix water, polystyrene Masterbatch, sodium butylnaphthalene sulfonate, polyvinyl alcohol, butane, dicumyl peroxide, hexabromocyclododecane, and antioxidant BHT in a mass ratio of 1.6:1:0.03:0.002:0.1:0.008: 0.02: 0.003 mixing, impregnation reaction at 72±2°C, pressure 0.9±0.1MPa, 100r / min speed for 10h can be obtained;

[0045] 3) Preparation of flame-retardant insulation layer: feed the modified expandable polystyrene obtained in step 2) into a pre-expansion machine with a steam pressure of 0.2 MPa and preheated to 70°C for pre-foaming. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com