Medical functional coating applying method and application

A coating method and coating technology, which is applied in the direction of surface coating liquid devices, coatings, special surfaces, etc., can solve the problems of attenuation, return to untreated, a few minutes at a short time, and a day or two at a long time , to achieve enhanced chemical bonding, controllable thickness, and firm adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

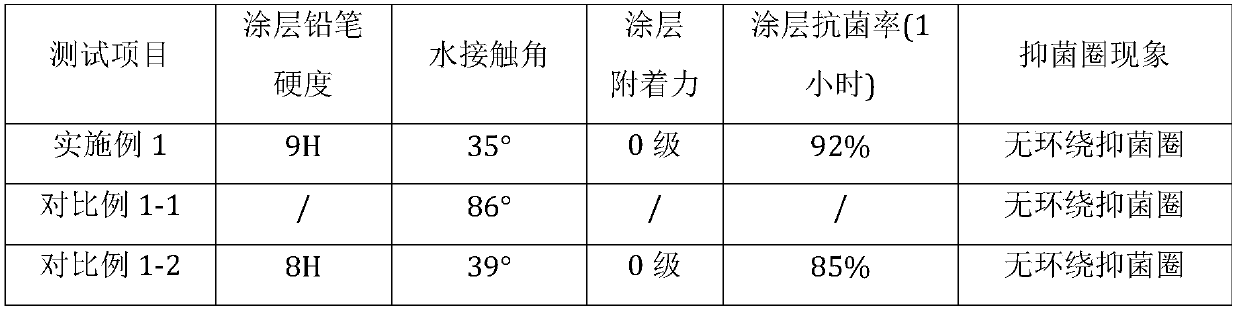

Embodiment 1

[0041] This embodiment relates to a titanium alloy internal fixation piece with an antibacterial coating, wherein the coating steps of the antibacterial coating are as follows:

[0042] 1) Put the titanium alloy internal fixation parts into an ultrasonic cleaning machine, wash them with acetone, ethanol, and water as cleaning liquids for 20 minutes each time, and then put the titanium alloy internal bone fixation parts into a blast drying oven to dry stand-by;

[0043] 2) Put the dried titanium alloy internal fixation into a vacuum plasma machine for plasma surface pretreatment; plasma surface pretreatment is carried out in two steps, the gas system used in the first step is carbon tetrafluoride and oxygen , The gas flow ratio is 1:2, the gas system used in the second step is oxygen, tetrahydrofuran and water, the gas flow ratio is 1:2:2, and the total treatment is 3 minutes;

[0044] 3) After breaking the vacuum, expose the titanium alloy internal fixation piece to the air a...

Embodiment 2

[0052] This embodiment relates to a medical syringe with a low-resistance coating, wherein the coating steps of the low-resistance coating are as follows:

[0053] 1) Take a 5ml polypropylene medical syringe in aseptic packaging, remove the needle and core rod piston, and then put it into a vacuum plasma machine for plasma surface pretreatment; plasma surface pretreatment is carried out in two steps, the first step uses The gas system is carbon tetrafluoride and oxygen, the gas flow ratio is 1:2, the gas system used in the second step is ethylene glycol dimethyl ether, oxygen and auxiliary gas ammonia, the gas flow ratio is 1:4:1 , a total of 5min;

[0054] 2) After breaking the vacuum, expose the medical syringe to the air at room temperature for two days, and then spray polysilazane solution on it; the polysilazane solution includes a coating substrate and a solvent, wherein the coating substrate is nanometer Inorganic polysilazane physically mixed and modified by silicon d...

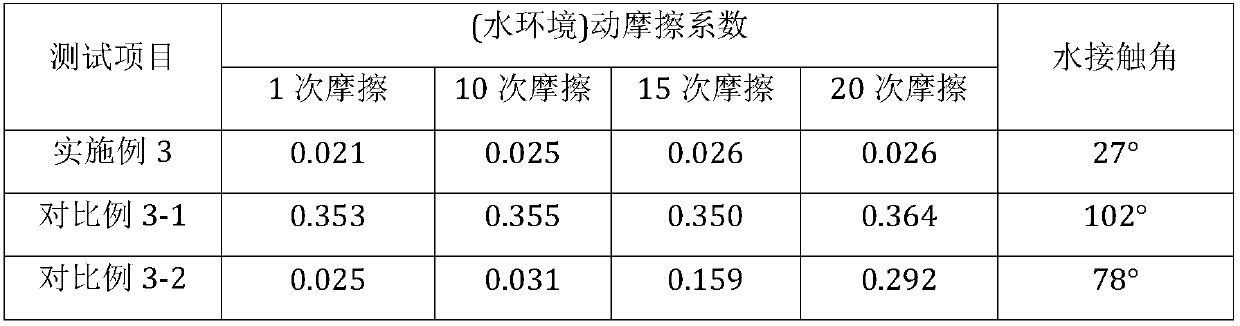

Embodiment 3

[0062] This embodiment relates to a silicone catheter with a hydrophilic super slippery coating, wherein the coating steps of the hydrophilic super slippery coating are as follows:

[0063] 1) Take the aseptically packaged silicone catheter and put it directly into a vacuum plasma machine for plasma surface pretreatment; the plasma surface pretreatment is carried out in two steps, and the gas system used in the first step is octafluoropropane and carbon dioxide , The gas flow ratio is 1:6, the gas system used in the second step is butadiene, carbon dioxide and auxiliary gas argon, the gas flow ratio is 1:3:1, and the total treatment is 5 minutes;

[0064] 2) After breaking the vacuum, expose the silicone catheter to the air at room temperature for two days, and then dip-coat it with a polysilazane solution; the polysilazane solution includes a coating substrate and a solvent, wherein the coating substrate It is a mixed solution of vinyl modified polysilazane, silane coupling a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com