Preparation method for safety electrode of ceramic sealing ring of power battery

A ceramic sealing ring and ceramic sealing technology, applied in the directions of copying/marking methods, sealing materials, battery pack components, etc., can solve the problems of inconsistent thickness of molybdenum-manganese layer, poor air tightness of packaging, low work efficiency, etc., to ensure quality , The effect of good sealing and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

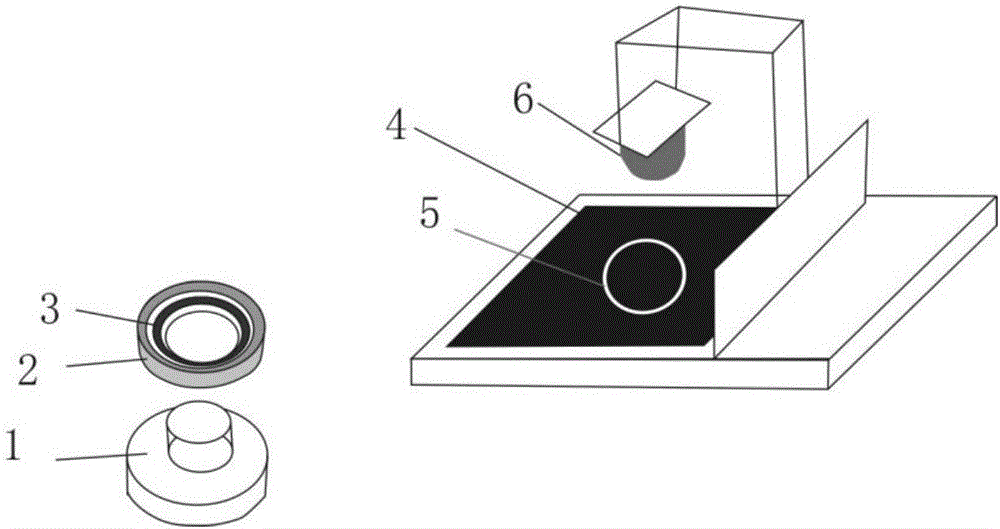

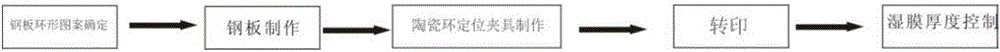

[0032] like figure 1 , 2 As shown, a method for preparing a safety electrode of a power battery ceramic sealing ring provided by the present invention comprises the following steps:

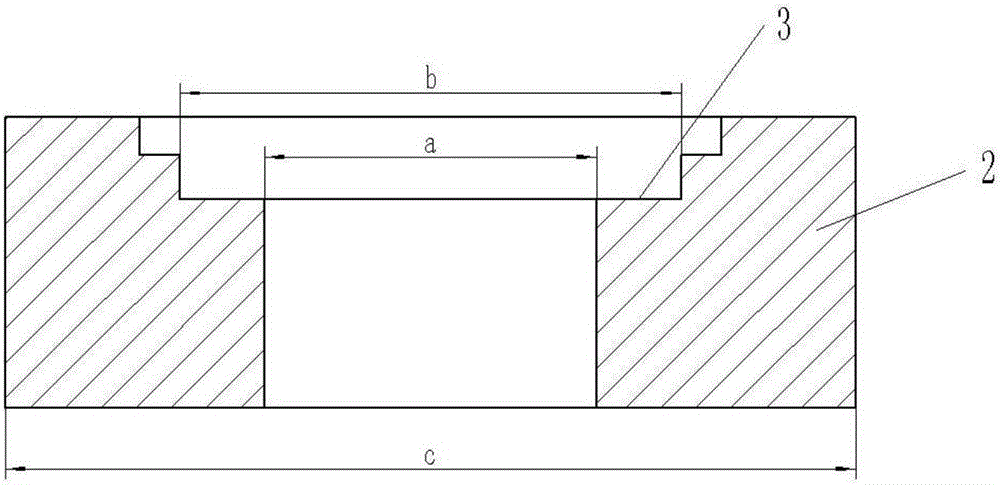

[0033] Step (1): According to the size of the stepped surface 3 of the groove of the ceramic sealing ring, make an annular pattern 5 on the steel plate 4, wherein the outer diameter of the annular pattern 5 is 0.5mm smaller than the outer diameter of the stepped surface 3 of the groove of the ceramic sealing ring, and the annular pattern 5 The inner diameter of 5 is 0.5 mm larger than the inner diameter of the stepped surface 3 of the groove of the ceramic sealing ring, and the depth of the annular pattern 5 on the steel plate 4 is 0.15 mm.

[0034] To illustrate with specific data: the outer diameter b of the stepped surface 3 of the groove of the ceramic sealing ring is 20 mm, the inner diameter a of the stepped surface 3 of the groove of the ceramic sealing ring is 14 mm, the outer diameter o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com