Paint spraying device for submerged speed reducer

A technology of reducer and spray head, which is applied in the direction of spraying devices, manipulators, manufacturing tools, etc., which can solve the problems of poor painting quality, low efficiency, and high labor cost, and achieve the effect of high painting quality, fast painting and low labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

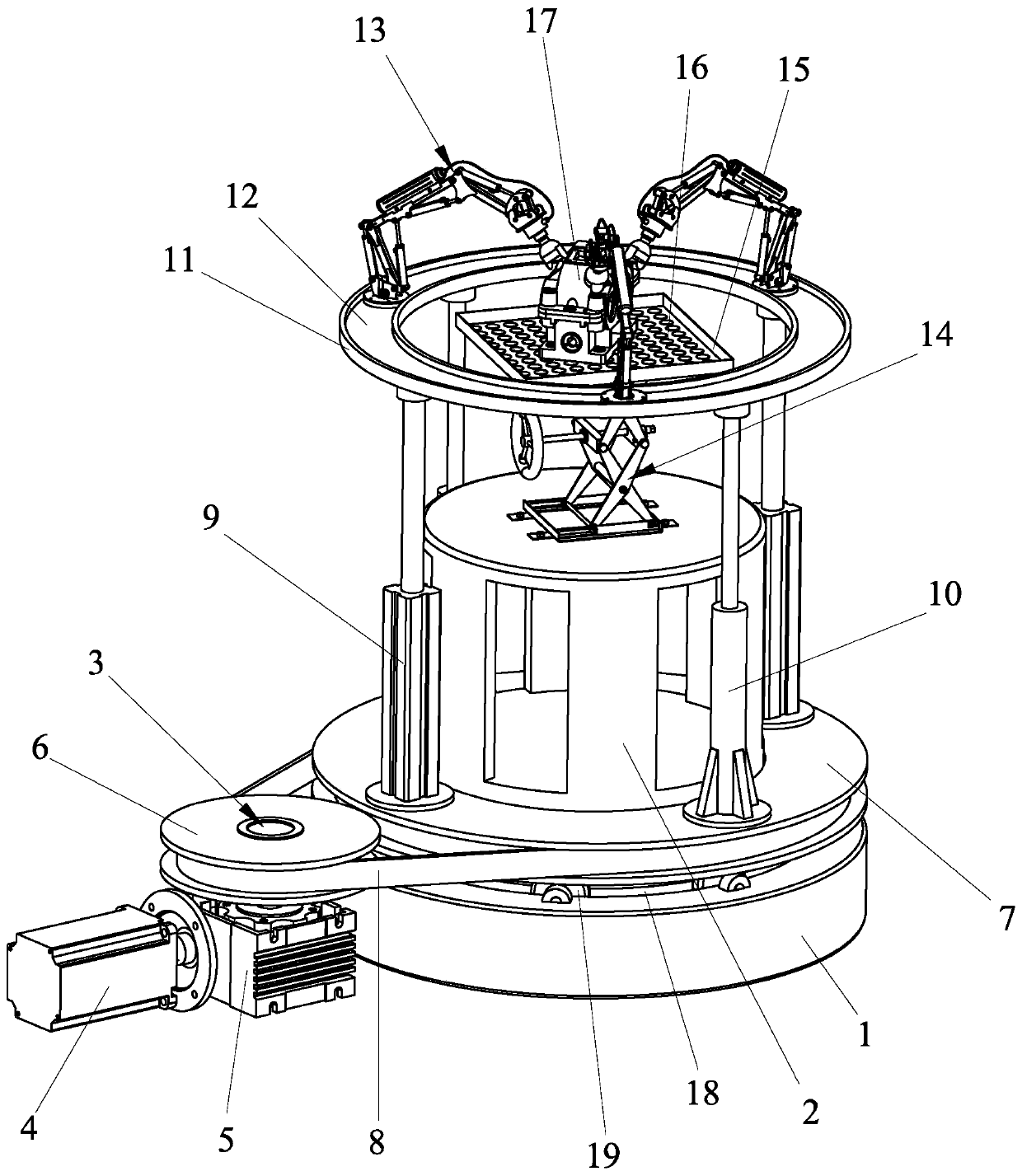

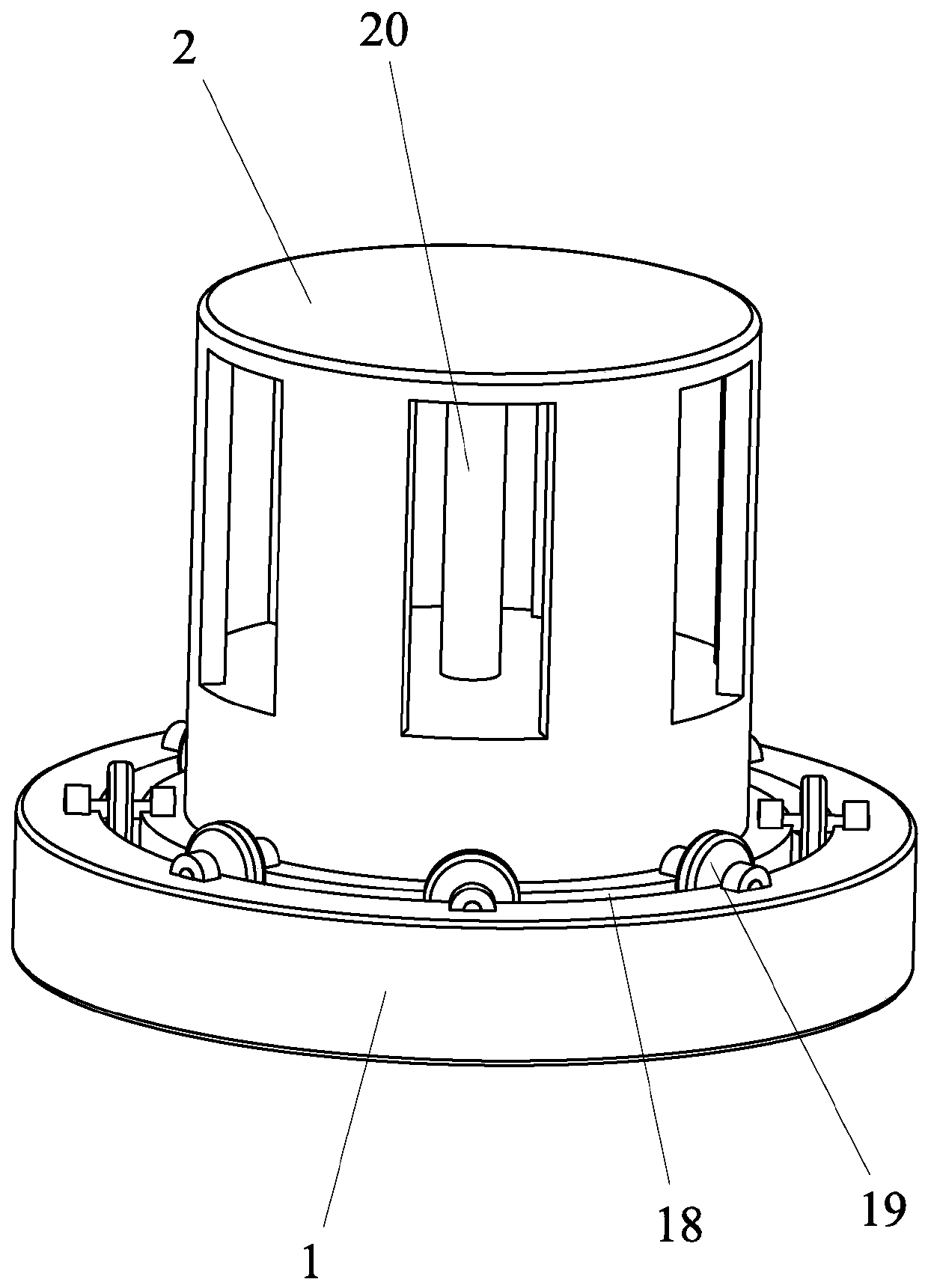

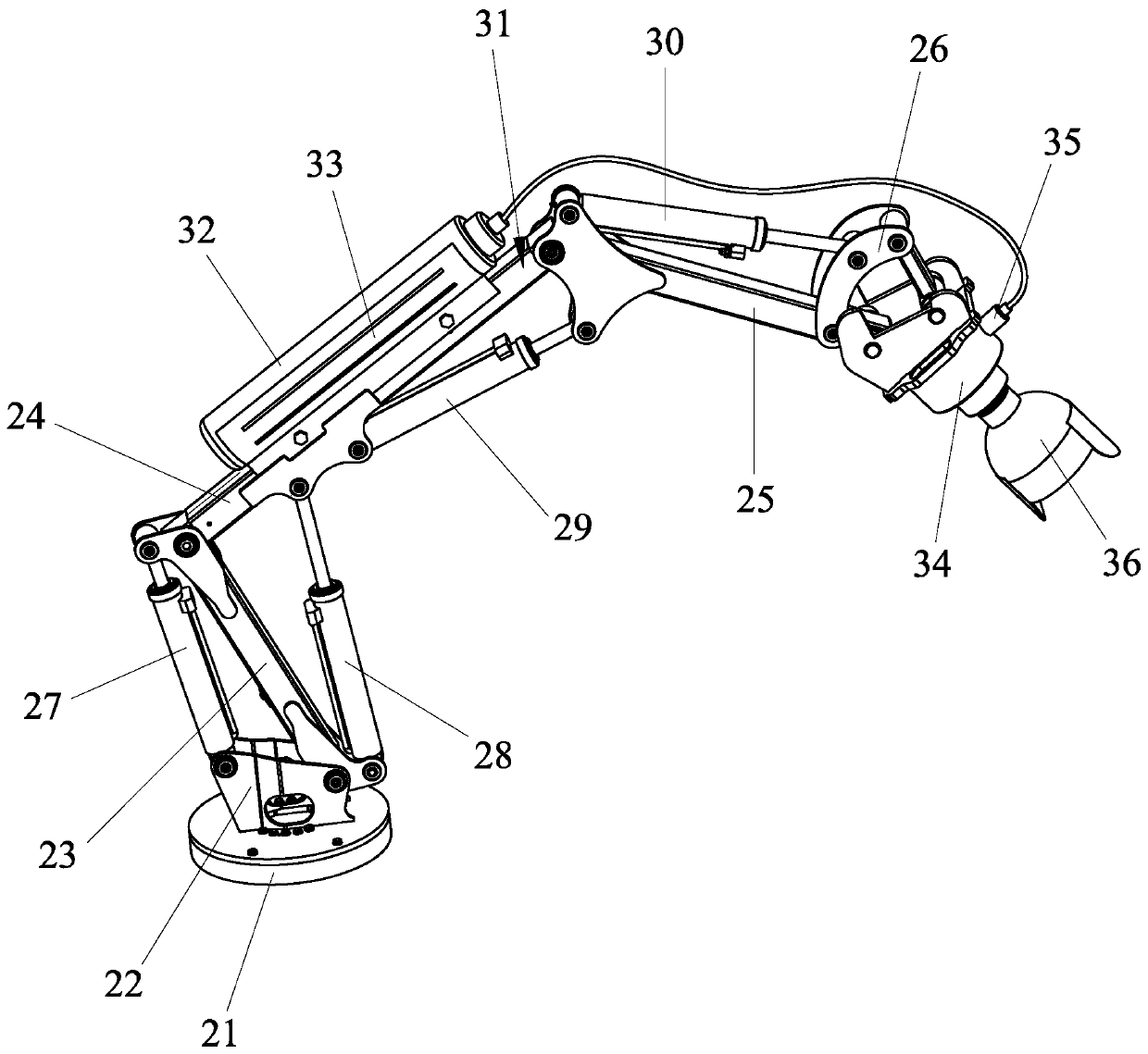

[0031] Embodiment: a paint spraying device for submerged reducer, constituted as attached Figure 1-5 As shown, including a base 1, the base 1 is provided with a fixed platform 2 and a rotary lifting device 3, and the fixed platform 2 is provided with an operation platform 15 for placing a submerged reducer 17, and the upper surface of the operation platform 15 is provided with There are a plurality of anti-skid pads 16, which can improve the friction between the operating platform 15 and the submerged reducer 17, and prevent the submerged reducer 17 from sliding. The rotary lifting device 3 is provided with a plurality of painting manipulators 13 acting on the submerged reducer 17, and the rotating lifting device 3 drives the painting spraying manipulators 13 to perform spiral upward or spiral downward movements; the painting spraying manipulators 13 include a chassis 21 , the chassis 21 is provided with a pneumatic linkage mechanism 31, the pneumatic linkage mechanism 31 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com