Arc fan nozzle used for reducing dust

A technology of nozzle and nozzle body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

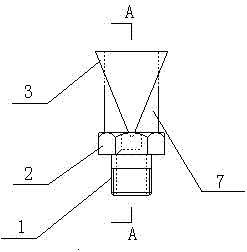

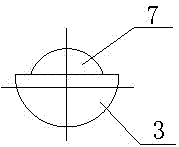

[0018] Such as Figure 1-Figure 3 As shown, the arc fan nozzle for dust reduction of the present invention is mainly composed of a nozzle body 2 and a guide body 3, the bottom of the nozzle body 2 is provided with a threaded joint 1, and the guide body 3 is located at the outlet of the nozzle body 2; The inner hole of the nozzle body 2 described above is divided into an inlet section 4, a gradual throat section 5 and an outlet section 6, which are sequentially connected into a unified body. Both the inlet section 4 and the outlet section 6 are cylindrical pipe sections, and the gradually changing throat 5 is a transition part between the inlet section 4 and the outlet section 6, and its inner diameter is gradually changed. The guide body 3 is a fan-shaped cone, the height of the fan-shaped cone is 1-10cm, and the central angle corresponding to the fan-shaped surface of the fan-shaped cone is between 30°-180°. The nozzle body 2 includes a connector and an extension section 7 p...

Embodiment 2

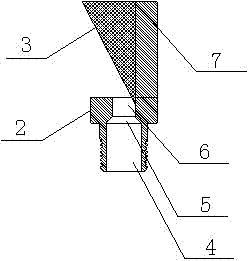

[0020] Such as Figure 4-Figure 6 As shown, the arc fan nozzle for dust reduction of the present invention is mainly composed of a nozzle body 2 and a guide body 3, the bottom of the nozzle body 2 is provided with a threaded joint 1, and the guide body 3 is located at the outlet of the nozzle body 2; The inner hole of the nozzle body 2 described above is divided into an inlet section 4, a gradual throat section 5 and an outlet section 6, which are sequentially connected into a unified body. Both the inlet section 4 and the outlet section 6 are cylindrical pipe sections, and the gradually changing throat 5 is a transition part between the inlet section 4 and the outlet section 6, and its inner diameter is gradually changed. The guide body 3 is a fan-shaped cone, the height of the fan-shaped cone is 1-10cm, and the central angle corresponding to the fan-shaped surface of the fan-shaped cone is between 30°-180°. The nozzle body 2 includes a connection head and a conduit 8 arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com