High-pressure gas mist linkage automatic fire extinguishing system

An automatic fire extinguishing system and high-pressure gas technology, which is applied in fire rescue and other directions, can solve the problems of secondary disasters of protective materials, open welding, water leakage, air leakage, and high system maintenance costs, and achieve fast and reliable pipe connection, reduce leakage, and fire extinguishing high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the present invention easier to understand, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation.

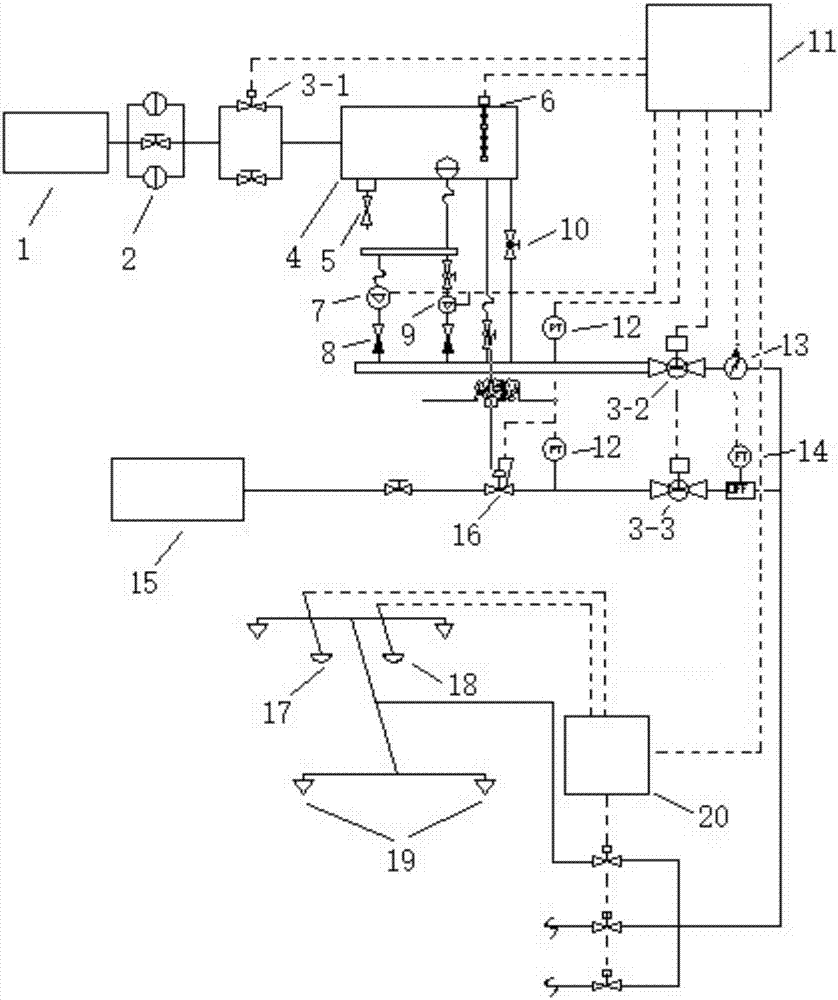

[0017] figure 1 It is a schematic diagram of the structure of the present invention, showing the various components of the present invention and their interaction with each other. according to figure 1 As shown, a high-pressure water supply system, a high-pressure nitrogen system, a fire alarm device 20, a smoke sensor 17, a temperature sensor 18 and a nozzle 19, the high-pressure water supply system includes sequentially connecting a water source 1, a filter 2, an electric control valve-3- 1 and water tank 4, the bottom of the water tank is connected to the primary water supply pipeline, the primary water supply pipeline is connected to the secondary water supply pipeline through the pipeline with the high pressure pump 7 and the check valve 8, and the primary water sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com