Atomizer having atomizing core with protective cover

A protective cover and atomizing core technology, applied in the field of atomizers, can solve the problems of fragmentation, reduce atomization effect, and small atomization volume, achieve large heating area, improve user experience, and large atomization volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

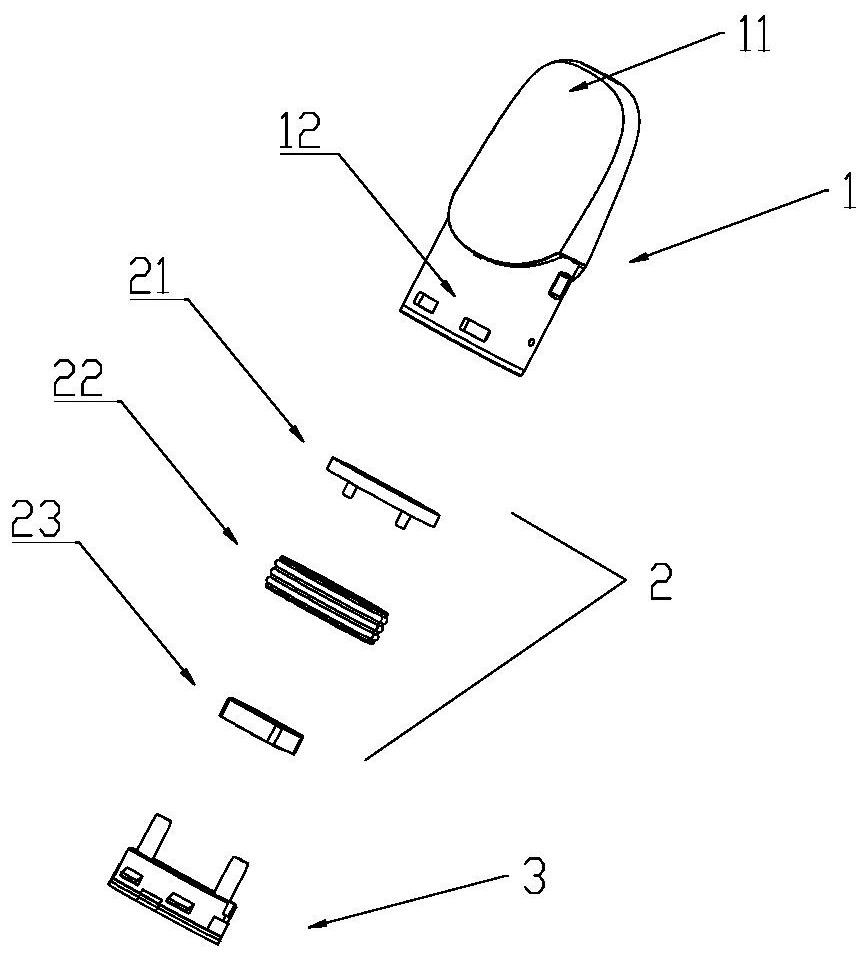

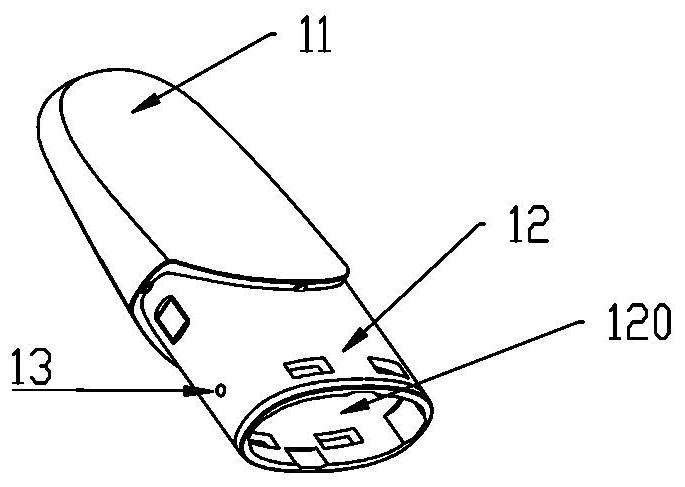

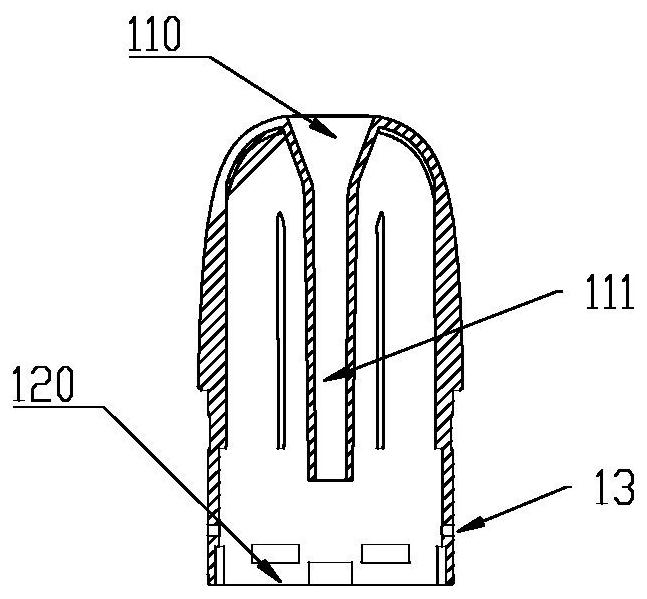

[0054] like Figure 1-Figure 3As shown, an atomizer with a protective cover for an atomizing core of the present invention includes a casing 1, the casing 1 includes a nozzle end 11 and a connecting end 12, the nozzle end 11 is provided with a suction port 110, and the suction port 110 is integrally formed downward. There is a suction pipe 111, the connecting end 12 is provided with an opening 120, the opening 120 is provided with a bottom cover 3 to seal it, the lower side wall of the casing 1 is provided with a casing air inlet 13, and the connecting end 12 can be connected with the battery assembly for It is composed of electronic atomization equipment (not shown in the figure).

[0055] like Figure 4-Figure 6 As shown, an atomizing assembly 2 is connected between the suction pipe 111 and the bottom cover 3, and a cavity is provided between the outer wall of the atomizing assembly 2 and the inner wall of the casing 1 to form a liquid storage chamber 10, and the liquid sto...

Embodiment 2

[0070] On the basis of the above-mentioned first embodiment, the structure of the air inlet hole of the casing, the air inlet hole of the bottom cover, and the atomizing core of this embodiment is slightly different.

[0071] like Figures 23-25 As shown, in this embodiment, the air inlet hole 13 of the casing is provided at the front side of the casing and the button hole where the lower part of the casing is connected with the convex buckle of the bottom cover 3 . Correspondingly, the bottom cover air inlet 33 is provided on the bottom cover side wall 36 above the convex buckle of the bottom cover 3 .

[0072] like Figure 26 As shown, the mist outlet channel of the atomizing core 23 is formed by a vertical groove 2320 disposed on the outer side of the protective cover 232 and the inner wall of the central cavity 2200 of the atomizing seat.

[0073] like Figure 27 As shown, the upper surface of the liquid guide 231 is located at the position of the orifice and is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com