Atomizing core with directional micropores

An atomizing core and microporous technology, which is applied in the direction of therapeutic atomizers, tobacco, inhalers, etc., can solve the problems of reduced aerosol reduction degree, reduced atomization volume, and different pore sizes, and achieves improved reduction. degree, increase the amount of atomization, and the effect of not easy to burn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

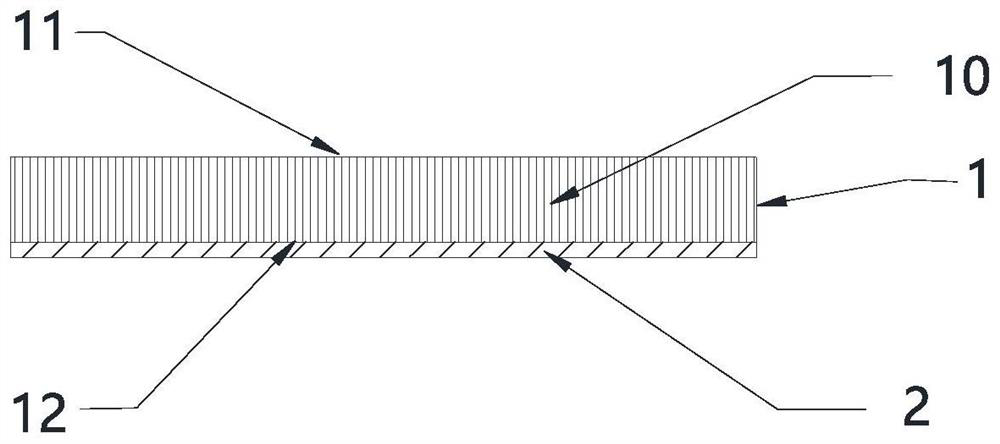

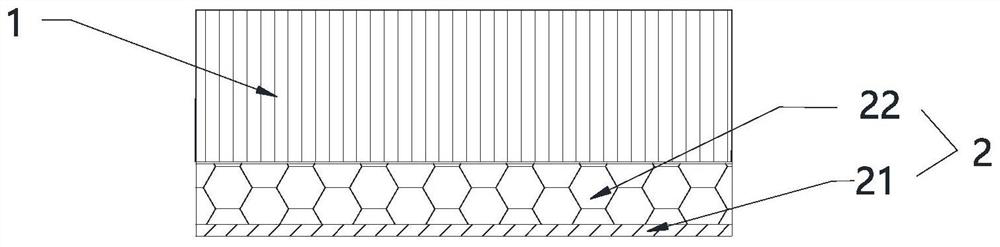

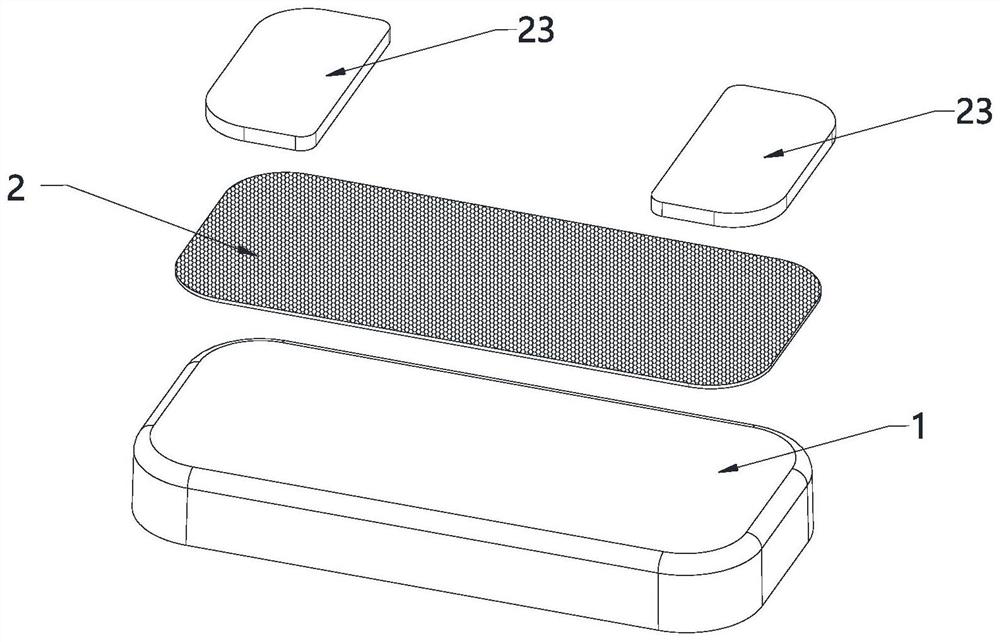

[0023] Such as figure 1 As shown, the present invention has an atomizing core with directional micropores, which is composed of a conductive liquid 1 and a heating element 2. The conductive liquid 1 is a solid that has a microporous structure and can be used to absorb, conduct, and store atomized liquid. The conductive liquid 1 is designed There is a liquid absorbing surface 11 and an atomizing surface 12. The liquid absorbing surface 11 can communicate with the liquid storage chamber in the atomizer to absorb and conduct the atomized liquid to the inside of the conducting liquid 1. The atomizing surface 11 can store the liquid in the conducting liquid 1. The atomized liquid is heated and evaporated to generate aerosol, and the heating element 2 is arranged on the atomized surface 11 . The conductive liquid 1 is provided with many directional micropores 10 from the liquid-absorbing surface 11 to the atomizing surface 12 . Oriented micropores refer to tubular micropores with o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com