Piezoceramic ultrasonic atomizer

A technology of ultrasonic atomizer and piezoelectric ceramics, which is applied in the field of atomizers, can solve problems such as inappropriateness, and achieve the effects of convenient design and arrangement, improved atomization effect, and reduced energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

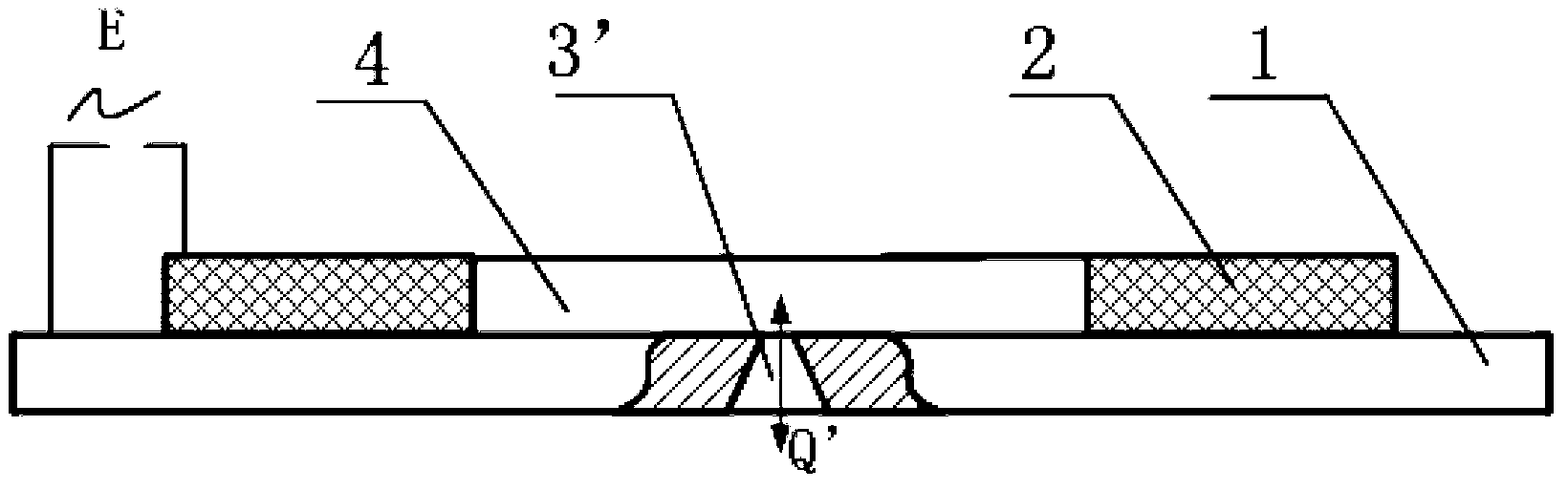

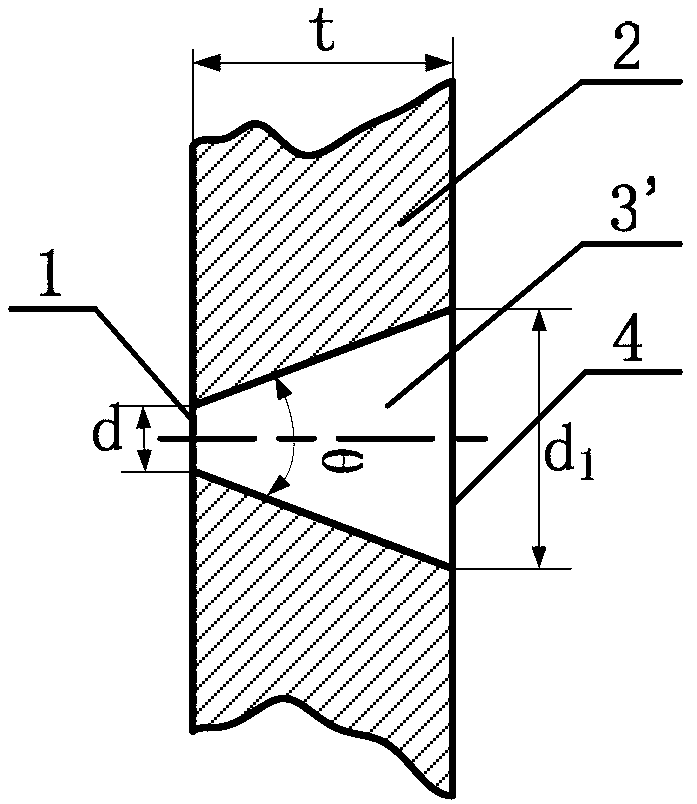

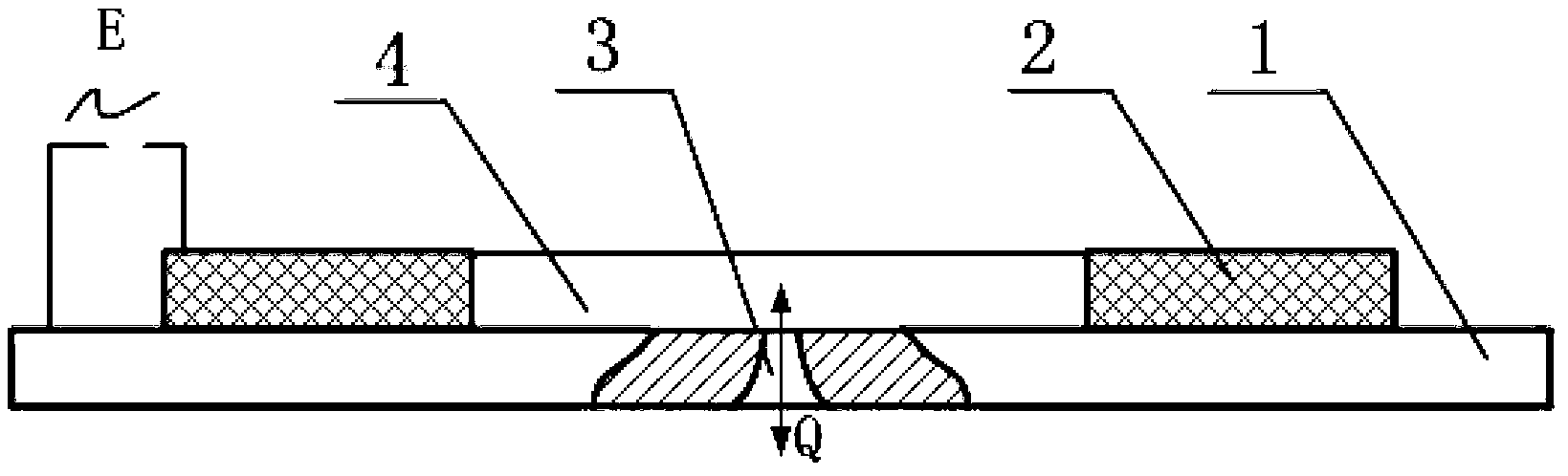

[0026] Such as image 3 , Figure 4 and Figure 6 As shown, the piezoelectric ceramic ultrasonic atomizer includes a connected metal diaphragm 1 and a piezoelectric ceramic ring 2, the outer diameter of the piezoelectric ceramic ring 2 is less than or equal to the diameter of the metal diaphragm 1, and the The central area of the piezoelectric ceramic ring piece 2 is provided with a through hole 4, and the area corresponding to the central area of the metal diaphragm 1 and the central ceramic ring piece 2 is provided with a group of dense atomization holes 3, and the atomization holes 3 face The first opening diameter of the piezoelectric ceramic ring piece 2 is smaller than the second opening diameter of the atomization hole 3 facing away from the piezoelectric ceramic ring piece 2, and the outline of the wall of the atomization hole 3 is curved. The metal diap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com