Atomizer structure

A technology for atomizers and components, applied in injection devices, liquid injection devices, etc., can solve the problems of large area of nozzle holes, high production cost, noise generation, etc., and achieve low cost of use, high structural strength, and reduced noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

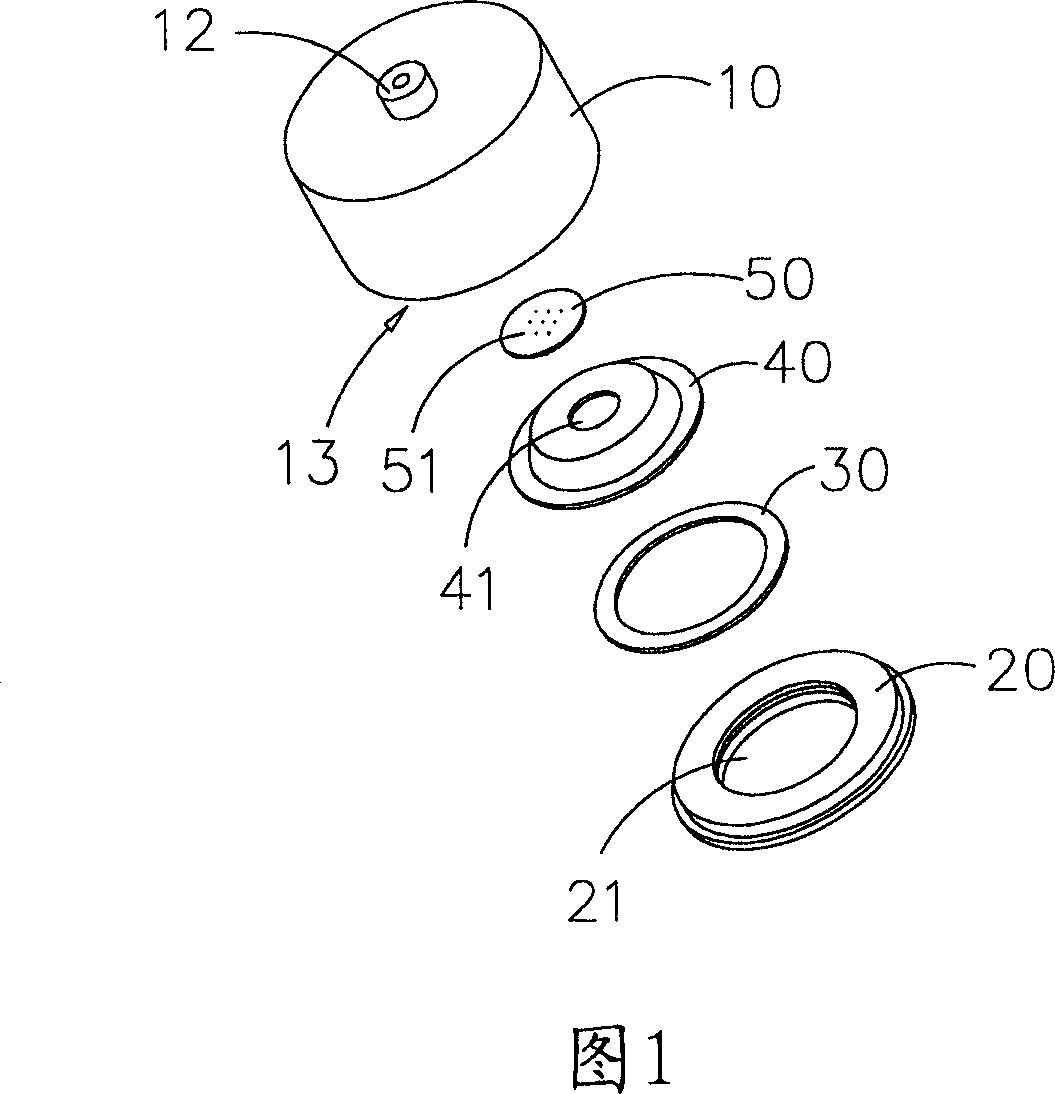

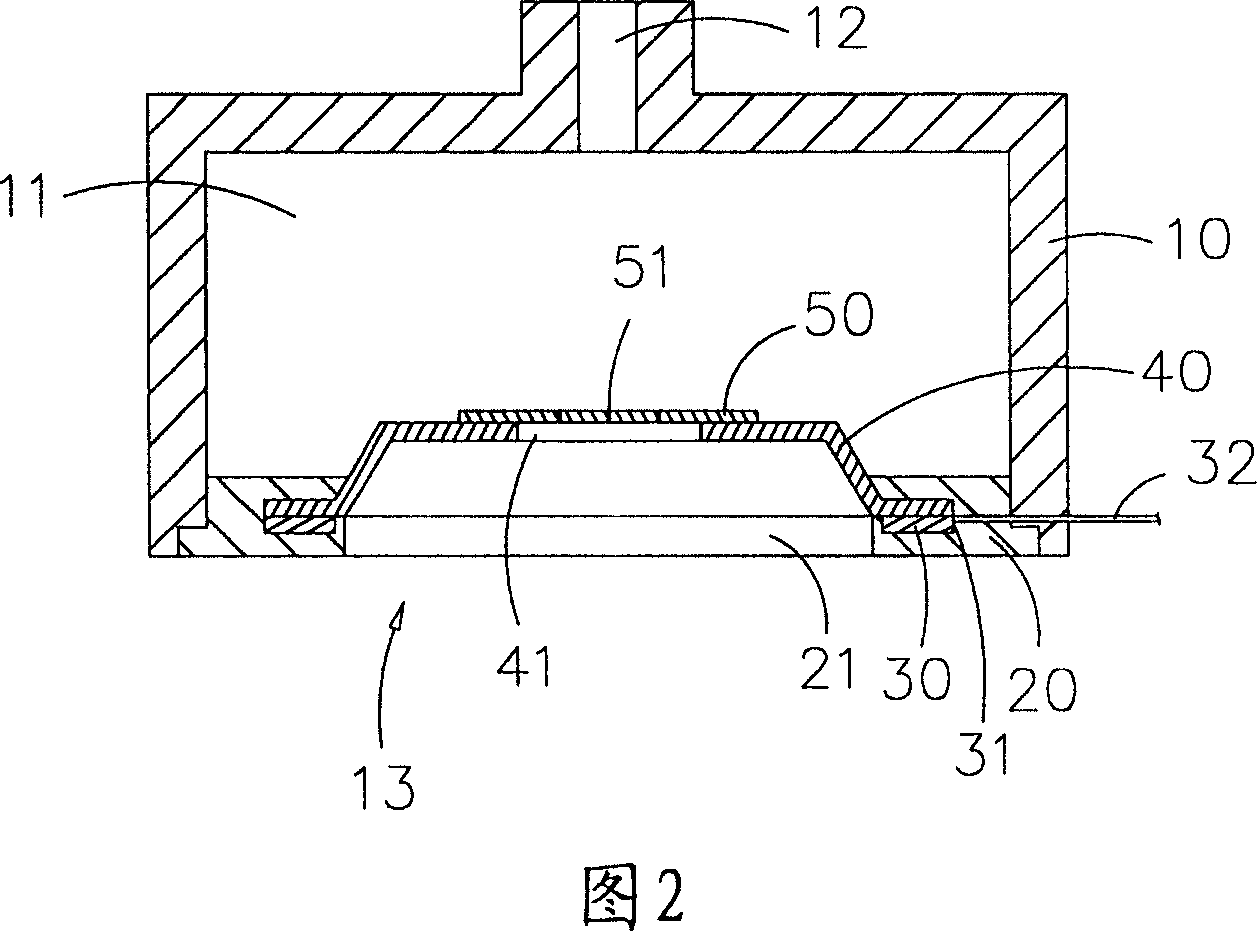

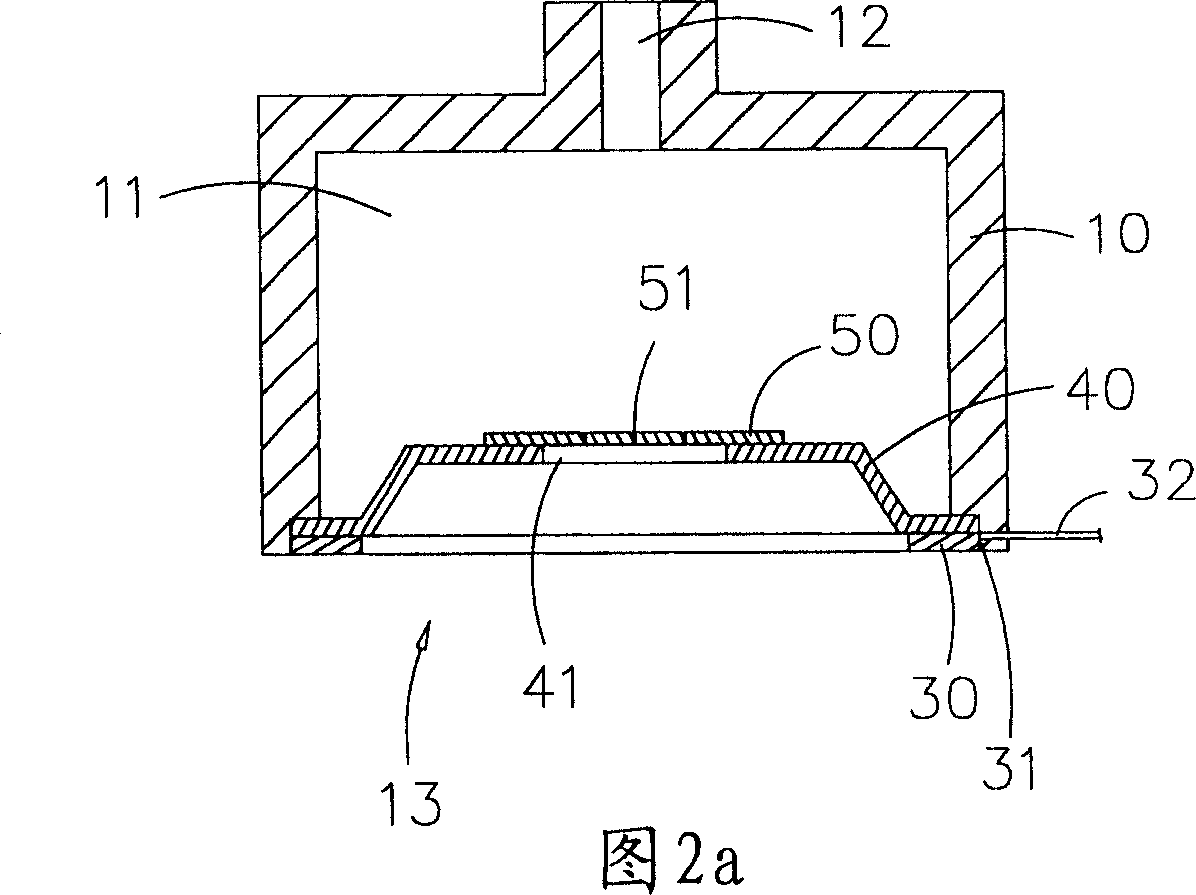

[0055] As shown in Figures 1 to 3, the present invention includes: a housing 10, which can be used to store liquid; a bearing 20, which is used to set related components; a vibration element 30, which can generate vibration force; an auxiliary vibration element 40, which has Increase the vibration amplitude effect, it can be flat plate or tool slope 401 or have step section; The purpose of slope 401 is to enlarge the nozzle hole sheet in the auxiliary vibrating element because of the slope geometric relationship when vibrating; a nozzle hole sheet 50 has several nozzle holes 51 When in use, the vibration of the vibration element 30 is used to transmit the vibration energy to the auxiliary vibration element 40, so that the auxiliary vibration element vibrates back and forth, and the nozzle hole plate 50 undulates and squeezes the liquid in the housing 10, so that the liquid is discharged from the nozzle hole 51 Fog is formed. The following will explain in detail:

[0056] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com