Freezing point indirect evaporation cooling type natural low-phase energy engine taking water as raw material

A technology of evaporative coolers and engines, which is applied in the direction of engine components, combustion engines, machines/engines, etc., can solve the problems of high application cost, achieve low cost, reduce the peak power consumption of the power grid, and achieve the effects of small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

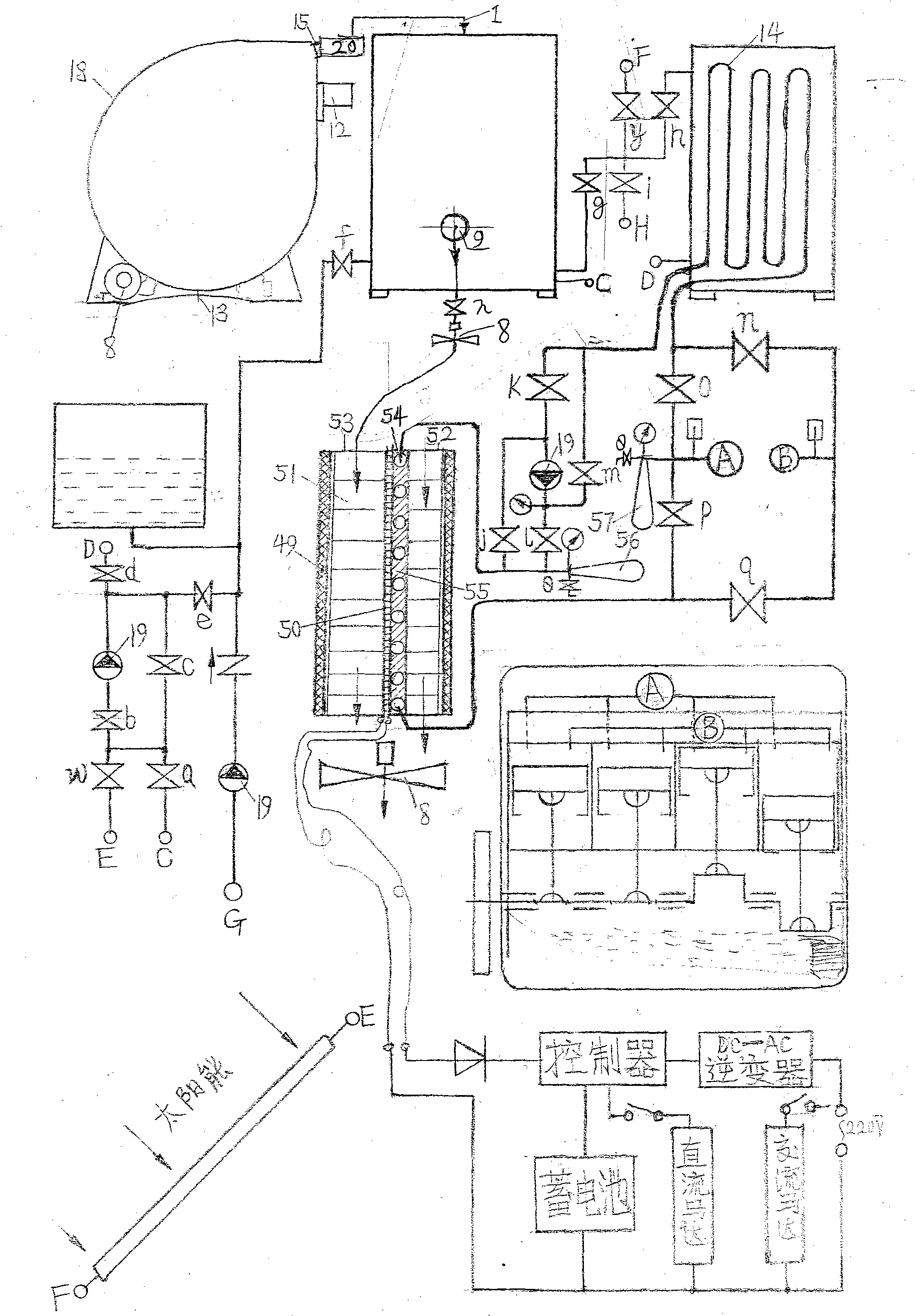

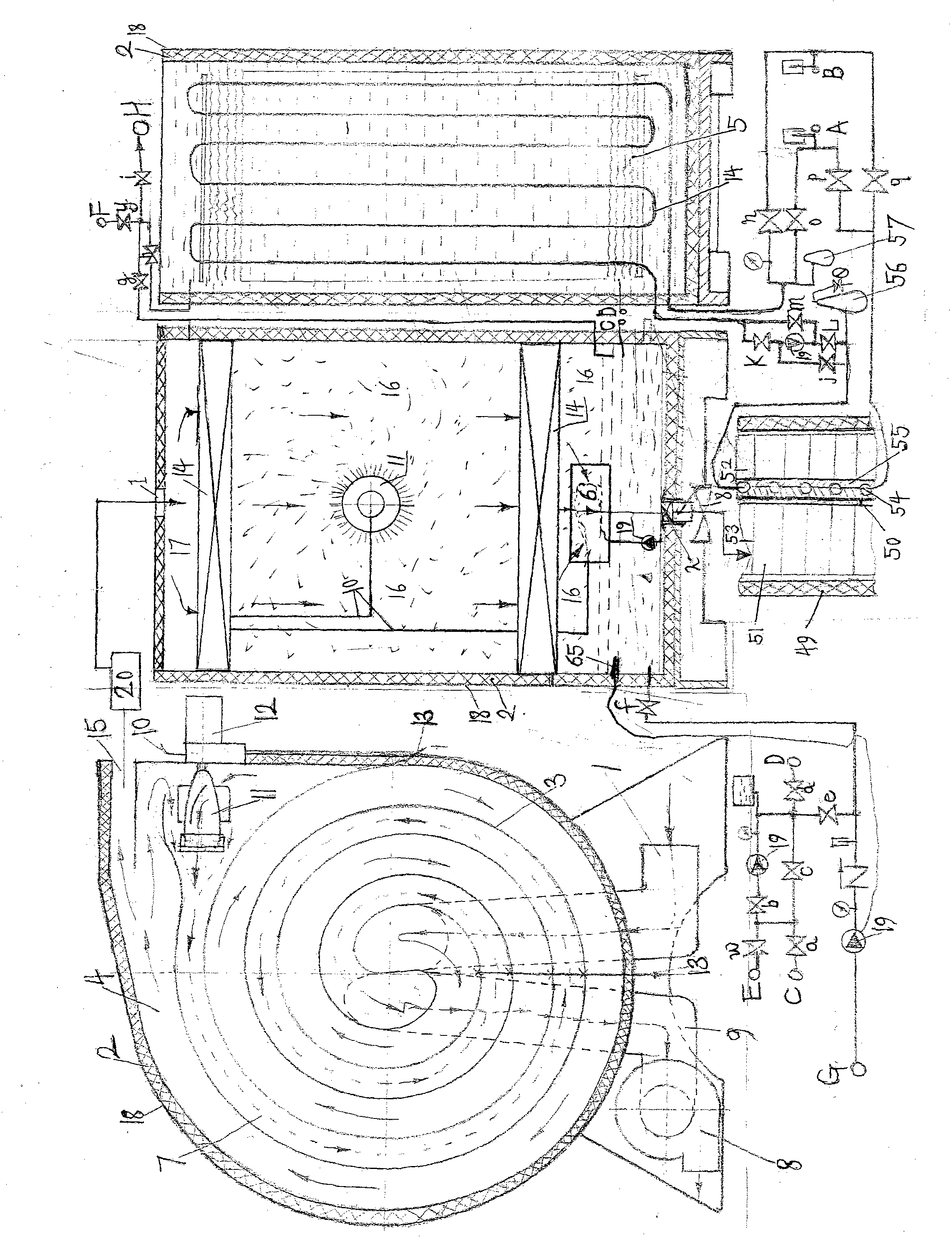

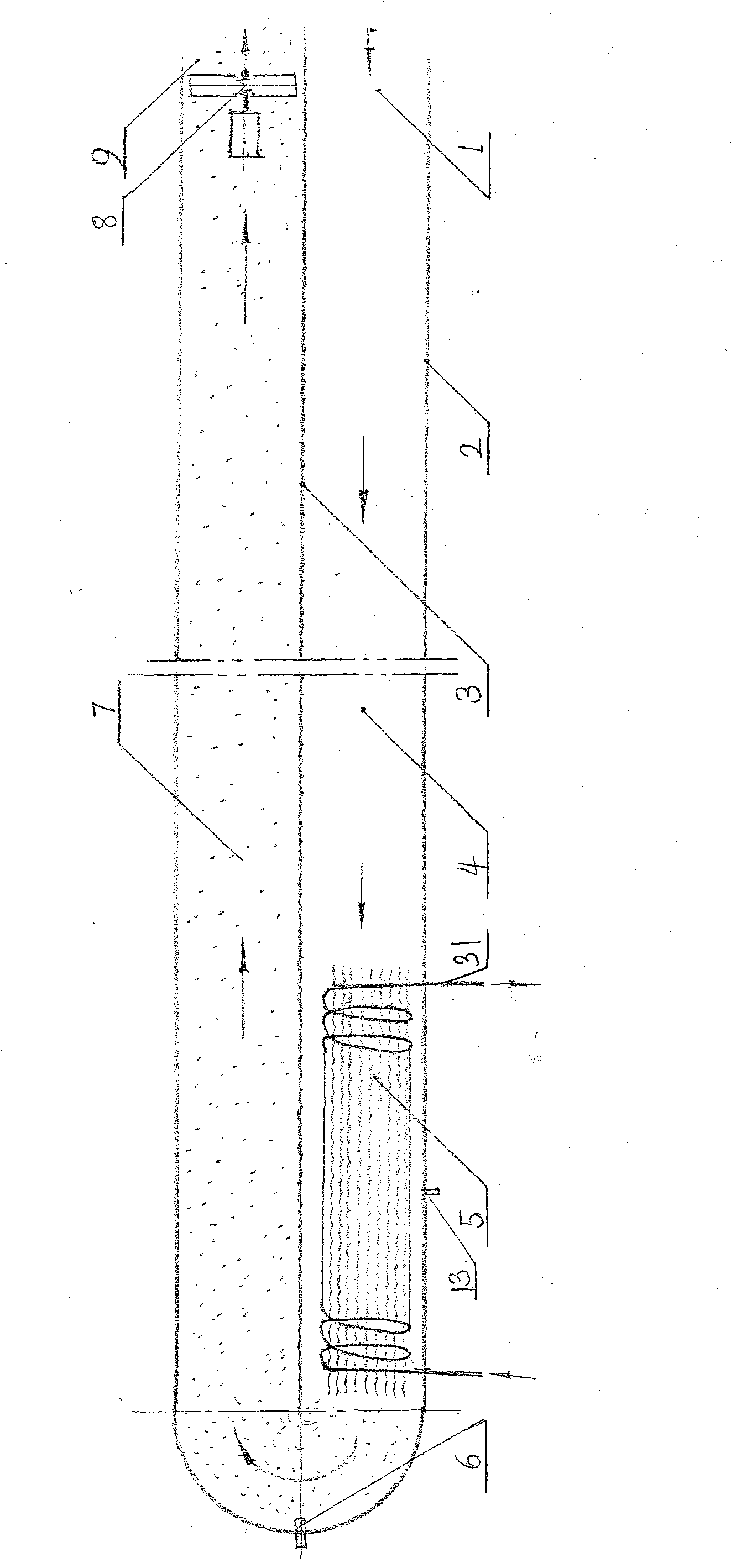

[0055] see figure 1 , figure 2 As shown in the embodiment, the water evaporation energy engine is connected to the outer dehumidifier 20 by the finished air outlet 15 of the spiral dew point indirect evaporative cooler, and connected to the air inlet 1 of the coil dew point indirect evaporative cooler, forming a freezing point indirect Evaporative cooler, solar energy, low-level energy collector of atmospheric thermal energy, piston engine, and thermoelectric engine are composed. The working cycle process: the dehumidifier 20 dehumidifies the primary air with sub-dew point temperature generated by the spiral dew point indirect evaporative cooler, Reduce the specific humidity to d≥3.5g steam / kg dry air, and then perform internal dehumidification, adiabatic humidification and heat exchange cycles in the coil cooler to produce finished air wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com