Novel atomizing core

A new type of atomizing core technology, applied in therapeutic atomizers, tobacco, food science, etc., can solve the problems of film quality, porous ceramic surface roughness, etc., to achieve safe and uniform quantitative atomization, stable interface and safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

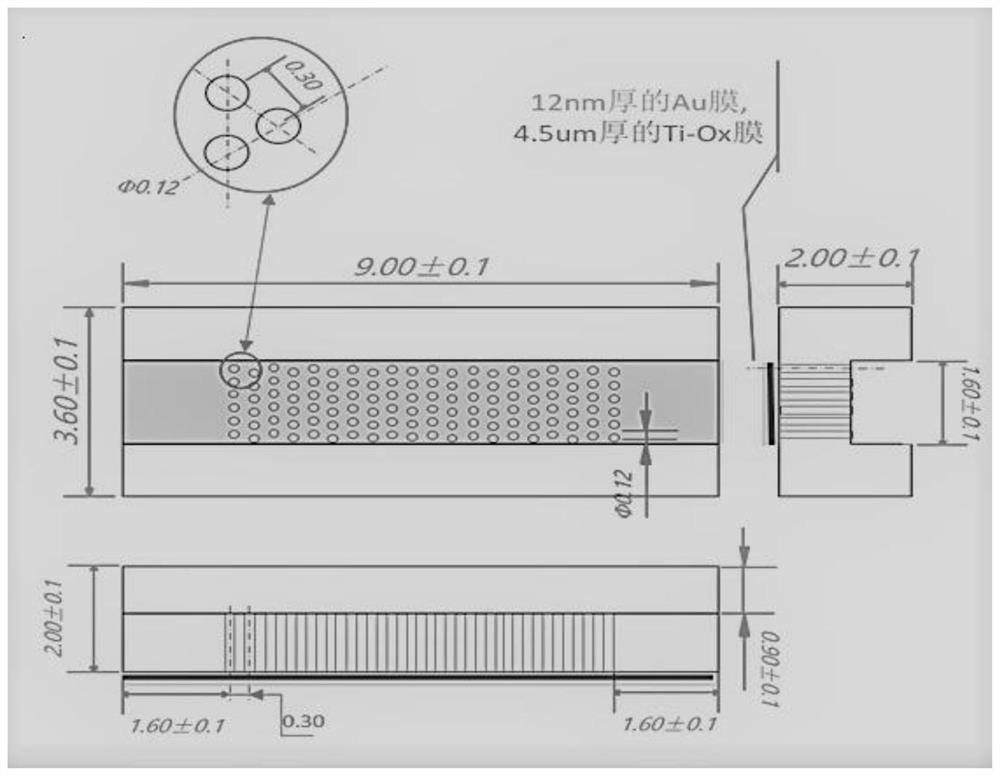

[0034] The substrate is made of alumina single crystal material. After numerical control processing into dimensions, the zoom laser is used to gradually form hole arrays on the substrate. The hole diameters are 120 microns, 100 microns, 80 microns and 60 microns, and the hole wall spacing is controlled separately. At 250 microns, 200 microns, 150 microns, and 100 microns, the array of holes can be arranged in a triangular close-packed arrangement, or in a matrix or other shape. Thereafter, a titanium oxide film or a tantalum oxide film with a thickness ranging from 0.35 microns to 5 microns is formed by sputtering or electron beam evaporation figure 1 The titanium oxide film is 4.5 microns in the middle), and the thickness is directly related to the oxygen component in the film. According to different oxygen content designs, a passivation film is covered on the surface of the film with low oxygen content, such as a gold film of about 12 nanometers (such as the attached figure...

Embodiment 2

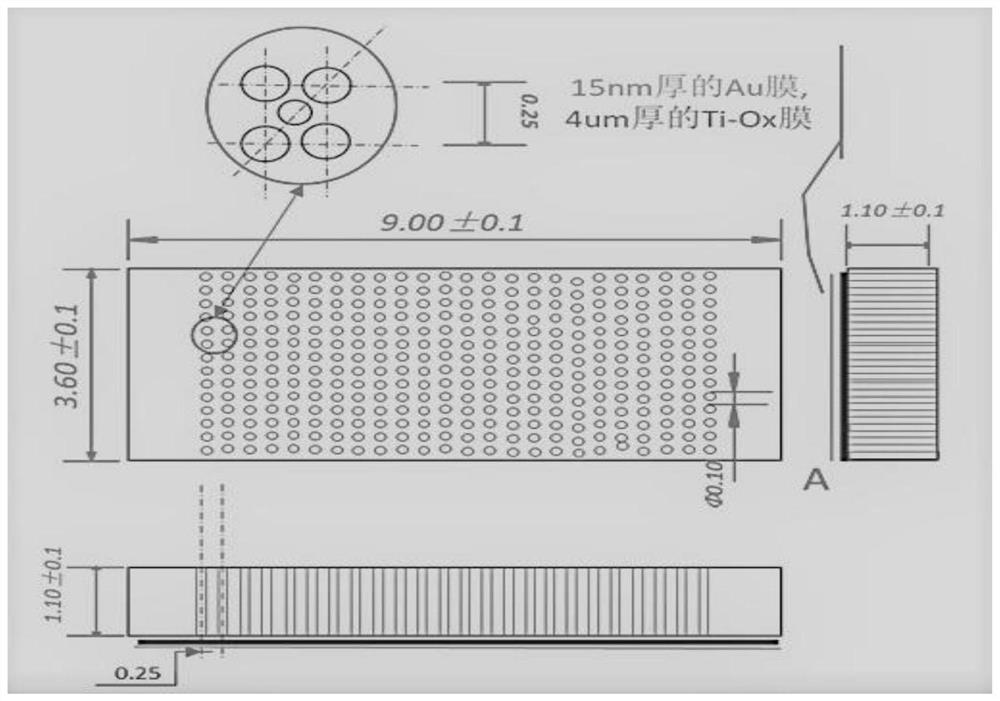

[0036] The substrate is made of alumina single crystal material. After numerical control machining into dimensions, the zoom laser is used to gradually form a hole array on the substrate. The diameter of the holes is 100 microns, and the distance between the hole walls is controlled at 200 microns. The hole arrays are closely packed in triangles. Arrangements can also be arranged in a matrix or other shapes. Thereafter, a titanium oxide film or a tantalum oxide film with a thickness ranging from 0.35 microns to 5 microns is formed by sputtering or electron beam evaporation figure 2 The titanium oxide film is 4 microns in the middle), and the thickness is directly related to the oxygen component in the film. According to different oxygen content designs, a passivation film is covered on the surface of the low oxygen content film, such as a gold film of about 15 nanometers (such as the attached figure 2 ), and then form electrodes with safe conductive paste at both ends, and ...

Embodiment 3

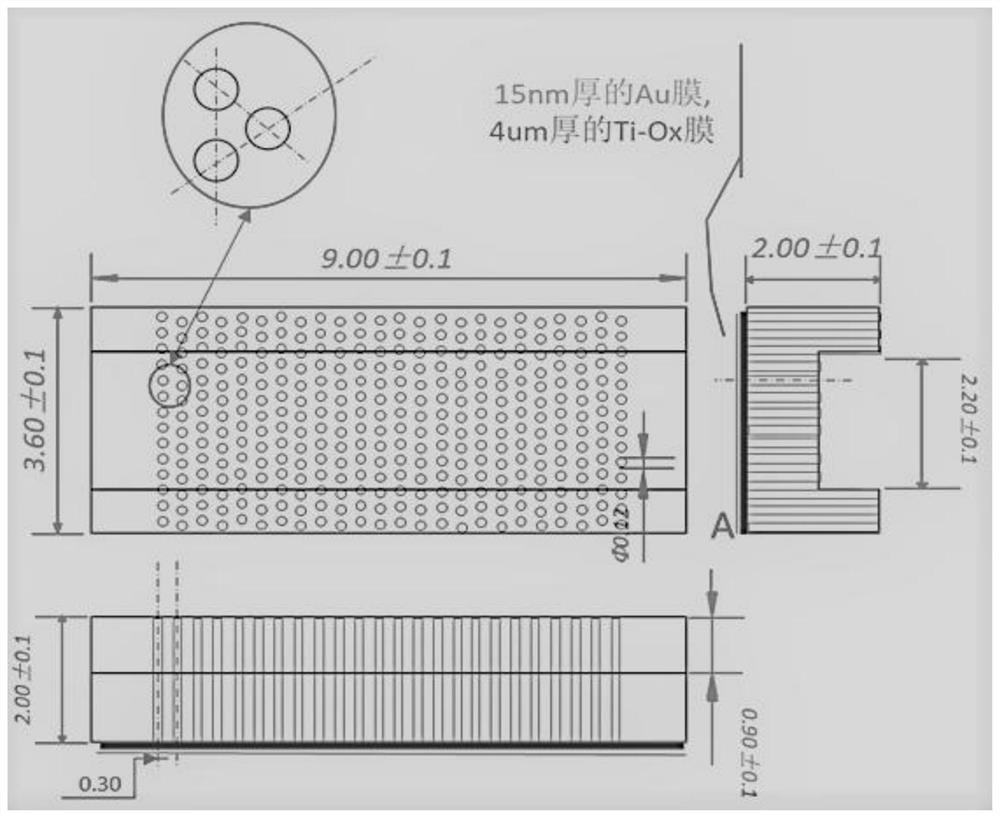

[0038] The substrate is made of transparent quartz glass. After numerical control processing into dimensions, a zoom laser is used to gradually form a hole array on the substrate. Arrays are arranged in a triangular close-pack, but can also be arranged in a matrix or other shape. Thereafter, a layer of titanium oxide film or tantalum oxide film with a thickness ranging from 0.35 microns to 5 microns is formed by sputtering or electron beam evaporation, and the thickness is directly related to the oxygen component in the film. According to the design of different oxygen content, the surface of the film with low oxygen content is covered with a passivation film, such as a gold film of about 15 nanometers, and then electrodes are formed with safe conductive paste at both ends and connected to the battery. The thin film deposited between the hole walls forms a uniform temperature field and nucleation center, and forms a controllable liquid flow and air flow channel during the atom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com