Lime slurry atomizing method and device for treating household waste incineration smoke

A technology for domestic waste incineration and lime slurry, which is applied in chemical instruments and methods, separation methods, dispersed particle separation, etc. The effect of nozzle clogging and energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

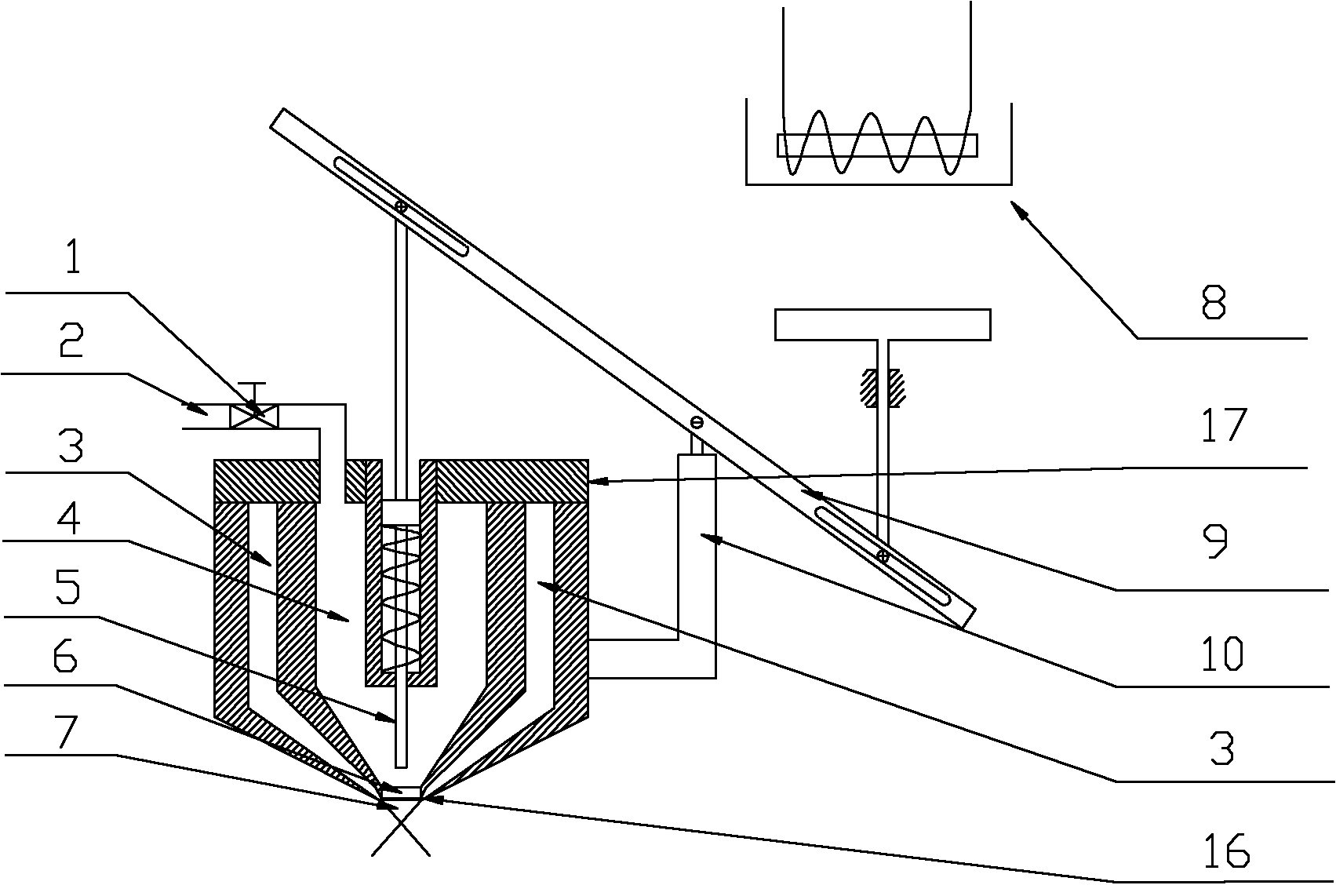

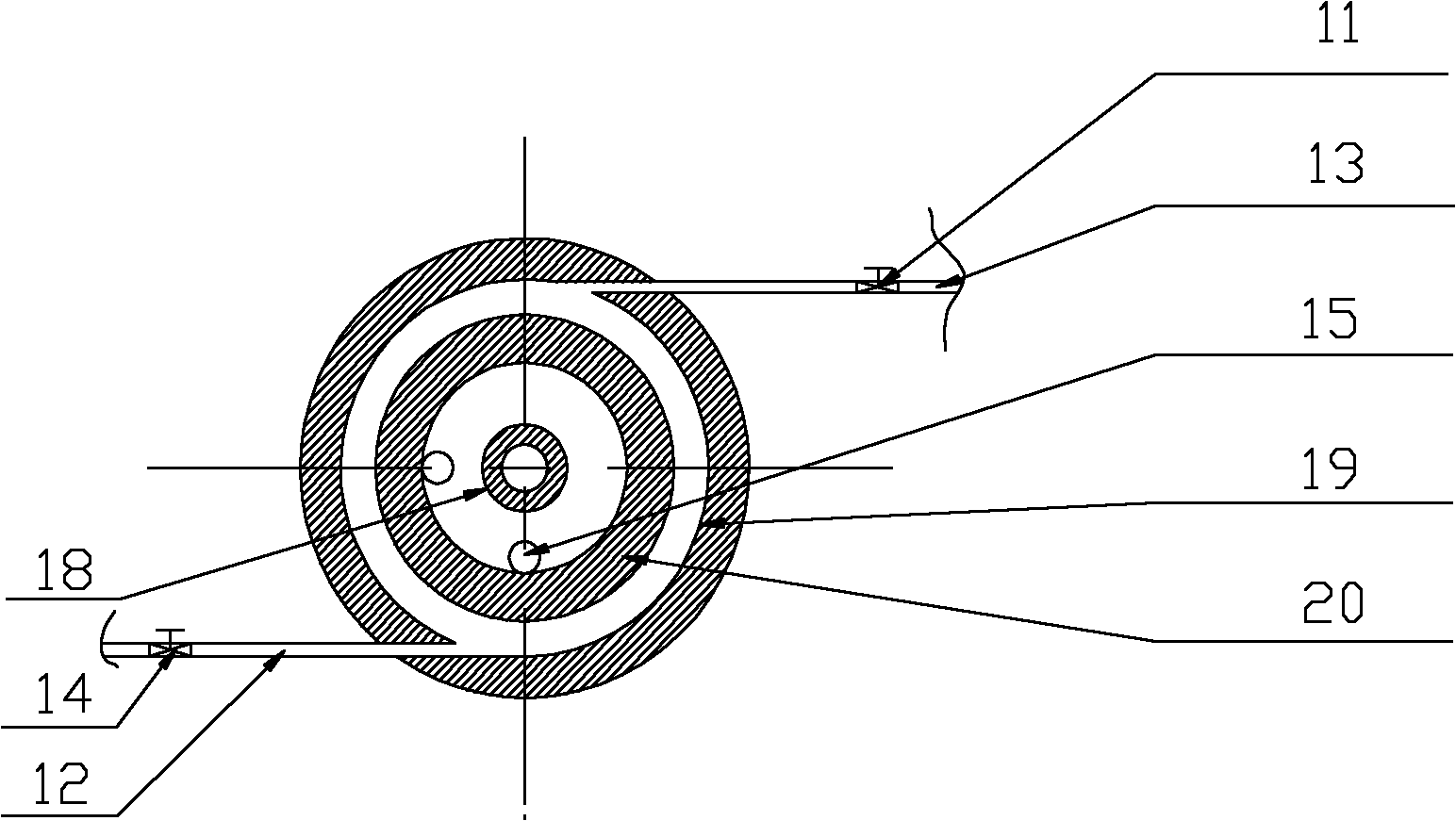

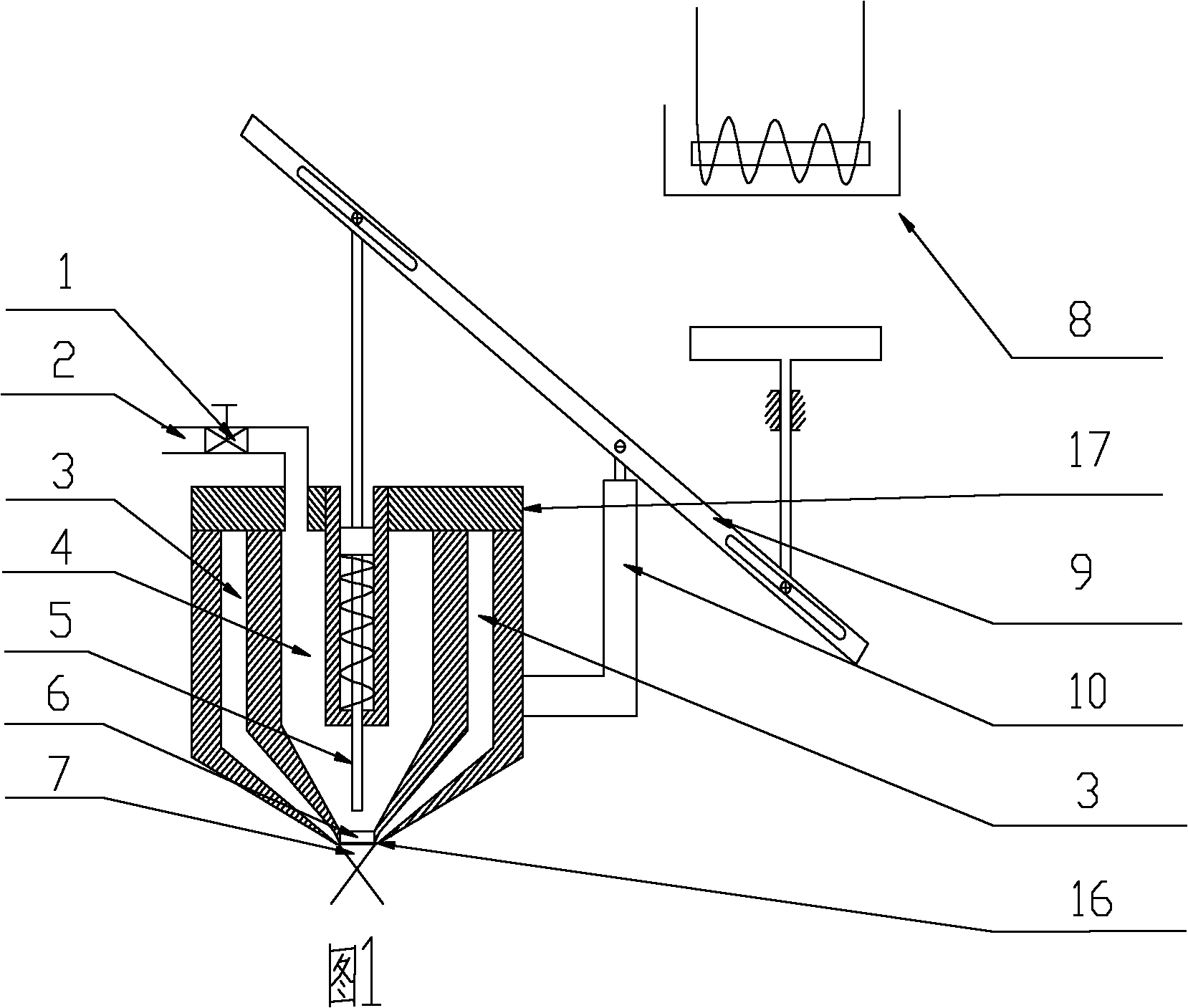

[0034] refer to Figure 1 to Figure 2 Examples of the present invention will be described.

[0035] Obviously, many modifications and changes made by those skilled in the art based on the gist of the present invention belong to the protection scope of the present invention.

[0036] An atomization device for treating domestic waste incineration flue gas, the atomization device includes a feed pipe 2, a second channel 4, a first water inlet pipe 12, a second water inlet pipe 13, a first channel 3, a first automatic flow control Valve 1, second automatic flow control valve 11 and third automatic flow control valve 14, nozzle 6, outlet 16, area 7, pressure monitoring port 15, electromagnet 8, connecting rod 9 rotate with the support of pole 10, needle core 5;

[0037]Outer tower body 19 and inner tower body 20 are the inside and outside closing conical container of an end, and the diameter size of inner tower body 20 is less than outer tower body 19, and the top of inner tower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com