Method for trapping coal-fired PM2.5 by using agglomeration of attapulgite turbid liquid

A technology of attapulgite clay and suspension, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. Friendliness, reunion Process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further elucidated below in conjunction with the accompanying drawings and specific embodiments of the description.

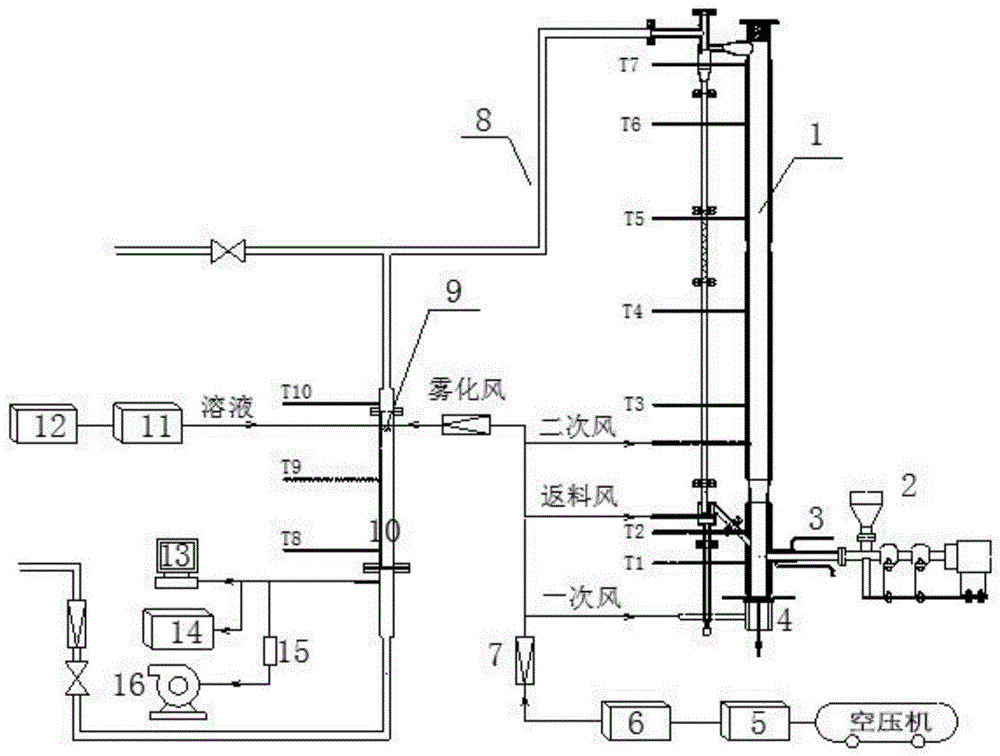

[0031] figure 1 Shown is the agglomeration of attapulgite clay suspension to trap coal-fired PM 2.5 The system diagram of the device is mainly composed of the circulating fluidized bed body, the air supply system, the feeding system, the feeding system, the electric control system, the agglomeration chamber and the spraying system. The fuel used in the experiment is American bituminous coal, and the particle size of the incoming coal is 0.6-1.5mm. During the experiment, the combustion temperature was controlled at 900°C, and the experiment was carried out in an air atmosphere. 1kg / h American bituminous coal was fed into the furnace by a screw feeder, and the air compressor provided primary and secondary air to the furnace to help the fuel burn fully. The unburned coal particles return to the furnace through the cyclone se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com