Micron-level powder material sieving equipment and sieving method

A material sieve and micron-level technology, which is applied in chemical instruments and methods, solid separation, and separation of solids from solids with airflow, etc., can solve the problems of bulky, low screening efficiency, and high maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

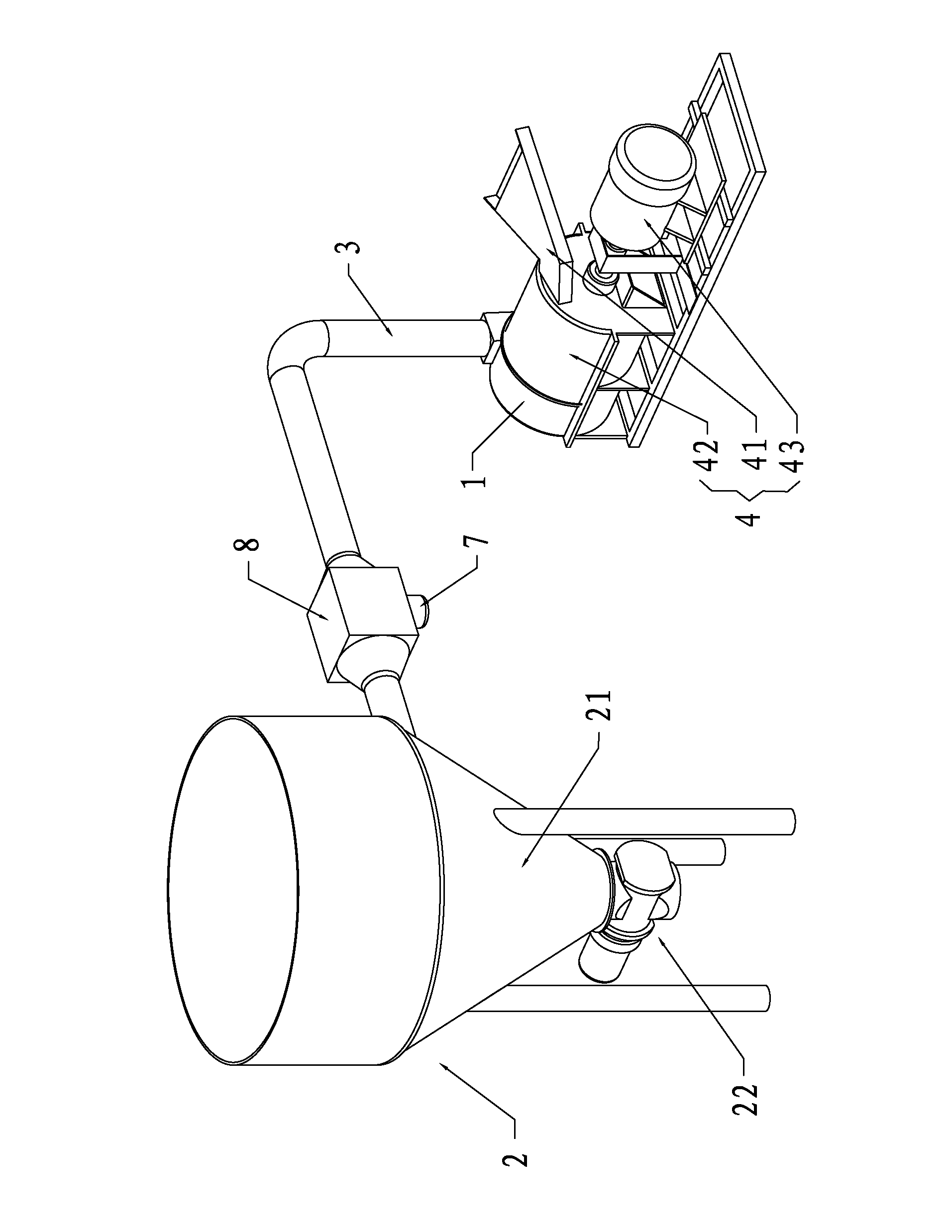

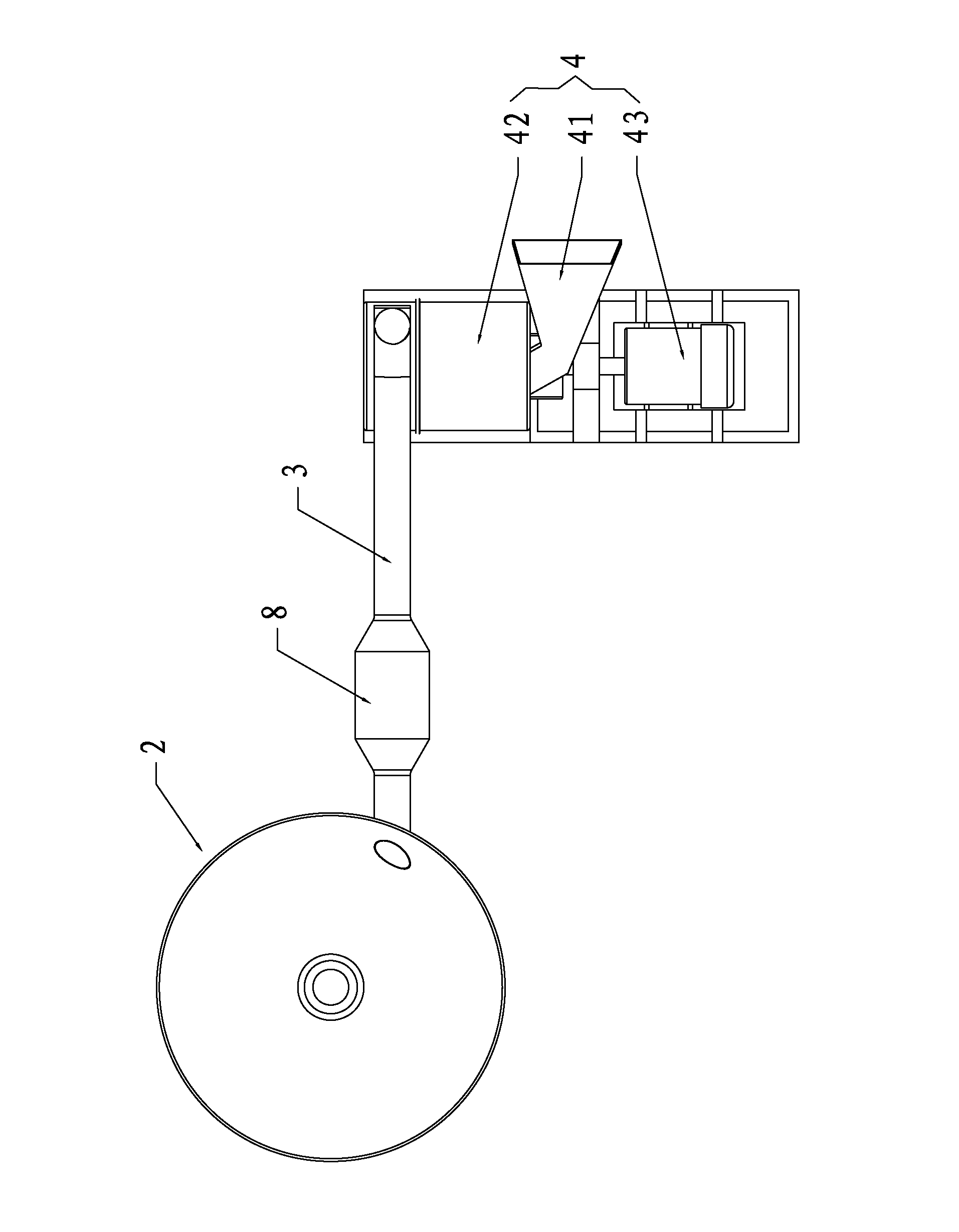

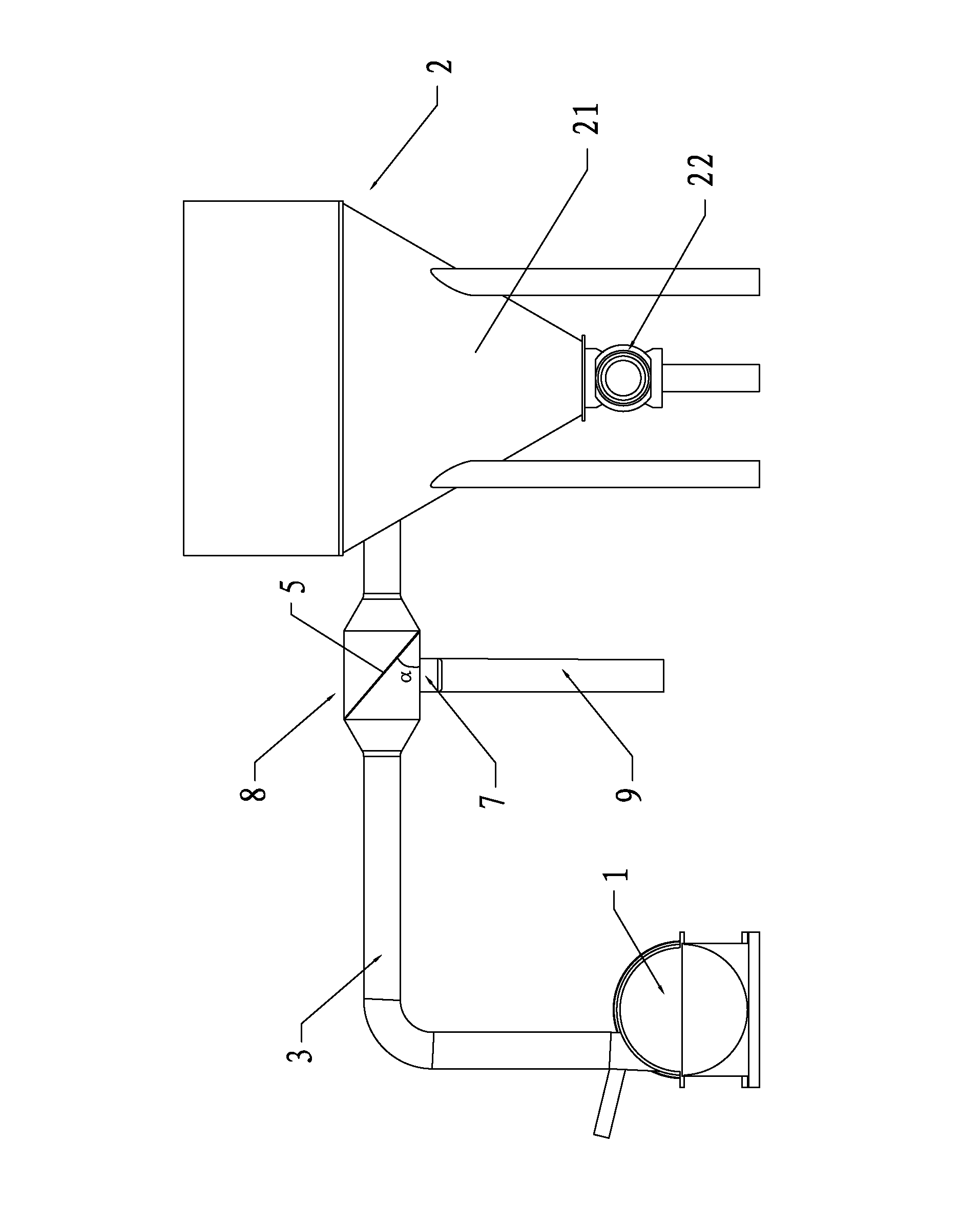

[0042] Such as Figure 1 to Figure 5 As shown, the screening equipment for micron-sized powder materials in this embodiment includes an air supply device 1, a collection device 2, and an airflow duct 3 arranged between the air supply device 1 and the collection device 2, so that The air supply device 1 is connected with a feeding device 4, and the position of the air flow duct adjacent to the collecting device 2 is provided with a screen slot 5, and the screen slot 5 is arranged obliquely, and the inclination angle is 20-80 degrees, so The screen slot 5 is inserted with a screen insert 6 cooperating with the screen slot 5, and the screen insert 6 is detachably laid with a screen, and the air flow duct 3 is adjacent to the screen A coarse material outlet 7 is provided at the lower end of the slot 5 .

[0043] When in use, start the air supply device 1, and the powder material to be screened will be blown to the screen by the strong airflow generated by the air supply device 1 ...

Embodiment 2

[0062] Such as figure 1 As shown, the difference between this embodiment and Embodiment 1 is that the feeding device 4 of this embodiment includes a pulverizer 42 connected to the air supply device 1, and the pulverizer 42 is connected to the air supply device 1 Both are driven and connected to a motor 43 through a motor shaft. The pulverizer 42 is connected to a hopper 41 , and a discharge regulating plate is provided at the lower end of the hopper 41 .

[0063] The air supply device 1 of the present embodiment is connected with a pulverizer 42, and the pulverizer 42 is arranged in front of the air outlet of the air supply device 1, and the raw materials are put into the hopper 41, and the feeding speed and the feeding speed of the raw materials are controlled by the discharge regulating plate. The amount of material, the pulverizer 42 crushes the raw materials into micron-sized powder materials, and the air supply device 1 blows the crushed powder materials to the screen for...

Embodiment 3

[0073] Such as figure 1 As shown, the difference between this embodiment and Embodiment 1 is that a hollow sieve body 8 is connected between the tail end of the airflow duct 3 of this embodiment and the collection device 2, and the sieve slot 5 It is arranged on the sieve body 8 , the two ends of the sieve body 8 communicate with the airflow duct 3 respectively, and the cross-sectional area of the sieve body 8 is larger than the cross-sectional area of the airflow duct 3 .

[0074] Specifically, the sieve body 8 is hollow and has a slightly smaller cylindrical shape at both ends, the sieve body 8 is arranged in parallel with the airflow duct 3, and the inner diameter of the sieve body 8 is larger than the inner diameter of the airflow duct 3, The screen slot 5 is welded to the screen body 8 . The two ends of the sieve body 8 are slightly smaller to ensure a stable connection between the sieve body 8 and the gas flow pipe 3, and the air tightness is good, which can effecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com